Predicting Anomalies Before Breakdowns Occur: Ultracompact Sensor Module Redefines the Status Quo of Equipment Maintenance

Factories and manufacturing sites need to prevent anomalies in machinery and equipment to minimize downtime. Productivity can be raised by predicting problems and performing maintenance preemptively, instead of reacting only after breakdowns have occurred. To facilitate this type of predictive maintenance, TDK has developed i3 Micro Module—the world’s first ultracompact sensor module featuring embedded edge AI.

The technical challenges of implementing predictive maintenance on the manufacturing floor

Generally, manufacturing sites are expected to operate their machinery and equipment at 100% capacity. This is because productivity can be held high by running at full capacity—in fact, many factories operate 24 hours a day, 365 days a year. Today, the concept of predictive maintenance is gathering considerable interest as a means to reduce the downtime of machinery and equipment. It refers to using sensors to monitor factory machinery and equipment in real time, predict anomalies and failures before they occur, and take preemptive action.

In contrast to traditional reactive maintenance, where actions are taken after failures or anomalies occur, predictive maintenance is believed to reduce the risk of failures, minimize manufacturing downtime, and extend equipment life. It is a major theme within the ongoing global movement toward smart factories*1, and is expected to be adopted in a variety of manufacturing settings.

In predictive maintenance, the real-time monitoring of equipment and machinery conditions using sensors is known as Condition Based Monitoring, which is considered to be a particularly key technology. Trying to achieve this, however, presents two major challenges. First, in factories, various sensors and analysis tools are generally provided as disparate systems, which complicates the collection and processing of data, thereby making it difficult to utilize the results of analyses. Secondly, due to wiring and other physical constraints, sensing at the positions desired by users is often unfeasible, hindering optimal condition monitoring.

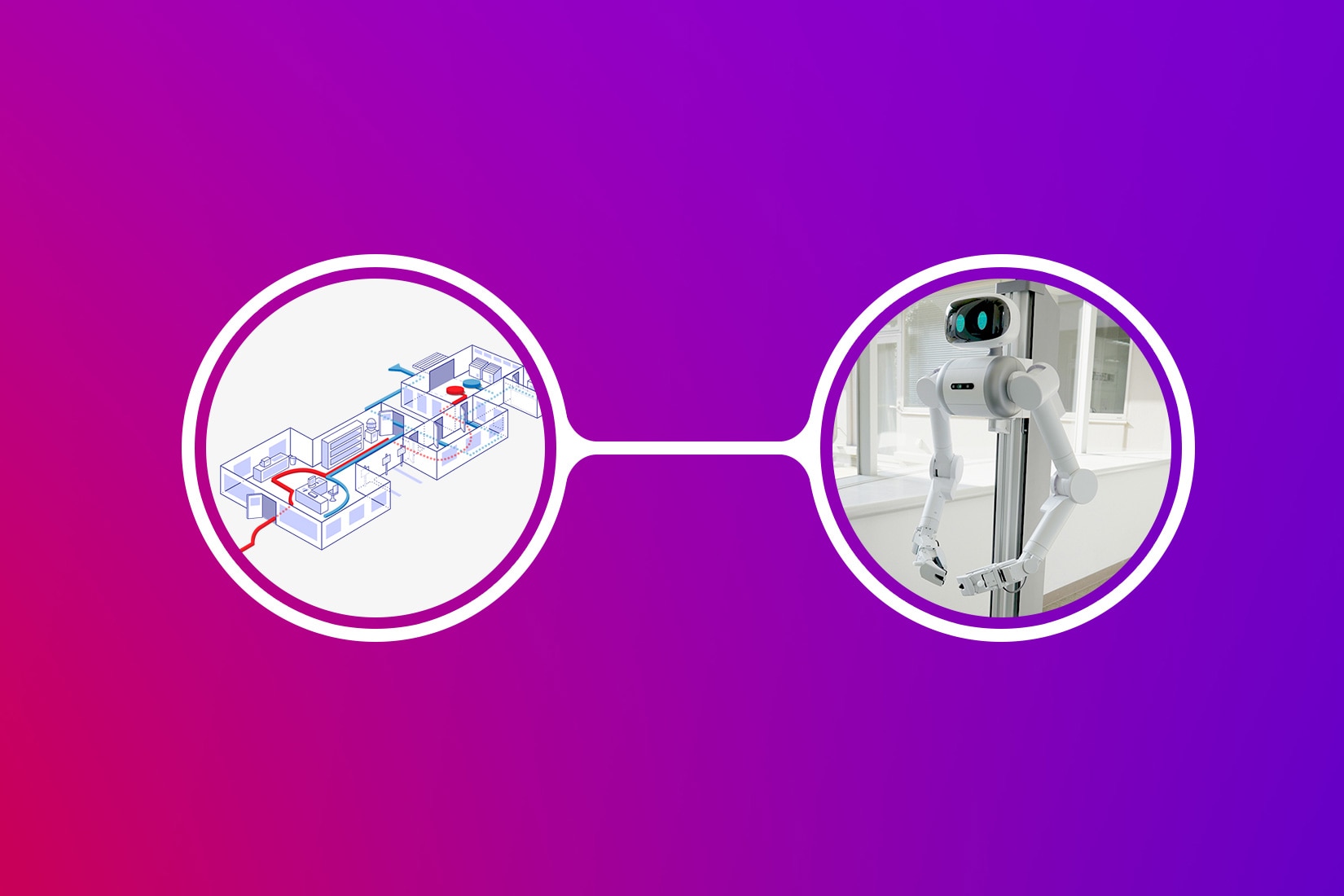

Predictive maintenance in factories

Sensors, edge AI and networking integrated into an ultracompact sensor module solution

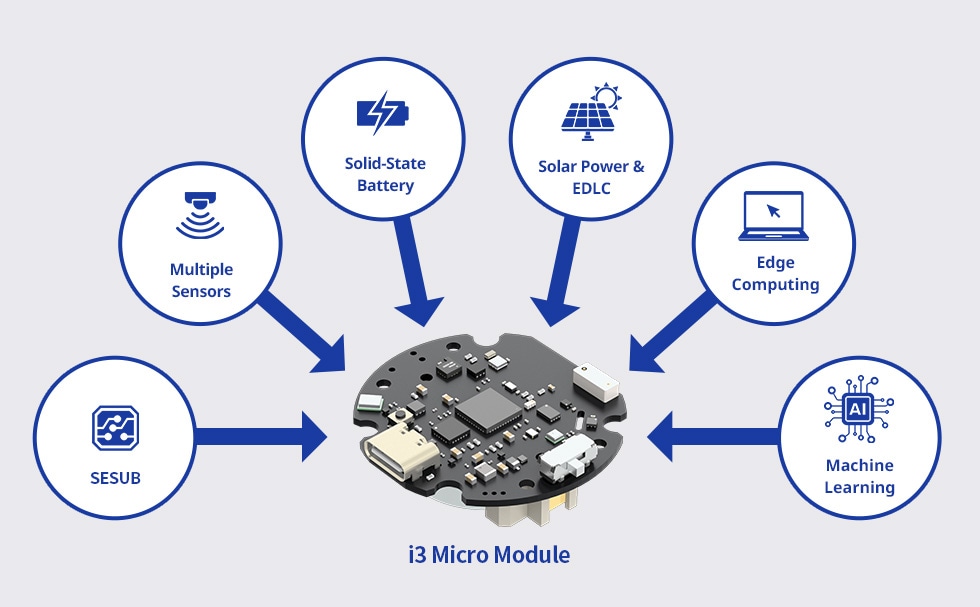

TDK has developed i3 Micro Module, the world’s first sensor module with built-in edge AI*2, overcoming the two aforementioned challenges.

i3 Micro Module integrates various sensors (vibration, temperature, sound, pressure etc.), edge AI, and mesh network*3 functionality into a single unit, facilitating data aggregation, integration and processing, which had been difficult in the past. Because it is an ultracompact, battery-powered wireless sensor module, users can achieve sensing at any desired position without physical constraints like wiring. This dramatically facilitates the prediction of anomalies in machinery and equipment, enabling an ideal Condition Based Monitoring implementation.

Numerous benefits are brought to the manufacturing floor, such as monitoring through visualized equipment information instead of relying on manpower, understanding the health of machinery and equipment to help extend their lives, and minimizing production downtime by preventing unexpected failures—thereby contributing to establishing an ideal predictive maintenance system.

i3 Micro Module is a multi-sensor

Predictive maintenance based on edge AI (conceptual illustration)

The great potential of sensor modules empowered by edge AI

CbM Development Unit

Condition based Monitoring Business Unit

Next Generation Products & Solutions Group

TDK Corporation

Battery-powered module products like i3 Micro Module require advanced technology to miniaturize and integrate sensors and wireless communications, and to optimally control everything inside the module in a power-efficient manner. The miniaturization and integration of such components and power-saving control were made possible by applying technologies cultivated through the vast experiences with electronic components and batteries, TDK’s core products. TDK has also long been conducting research and development on edge AI as an applied technology that builds on its sensor products, successfully developing the world’s first sensor module with embedded edge AI capabilities.

Kazuyuki Endo of TDK Corporation’s Next Generation Products & Solutions Group spoke about the future of i3 Micro Module. “We will continue to incorporate new sensing technologies and power supply technologies like solid-state batteries while we expand the range of applications, and integrate them into even smaller packages so that they can be embedded in all kinds of equipment. We also plan to further mature the embedded edge AI to enable it to continuously learn the situation at the point of installation and make autonomous decisions, thereby evolving the module to be able to support the types of advanced decision-making required at the forefront of integration.”

TDK is also envisaging offering i3 Micro Module to its customers as a solution that incorporates cloud integration.

Through advanced software and hardware development and integration, TDK will continue to help bring next generation smart factories to life.

The future of i3 Micro Module: A module that supports advanced decision-making

Terminology

- Smart factory: An initiative aimed at the forefront of manufacturing to promote the collection and utilization of real-time big data as well as the automation and autonomous operation of production lines by utilizing digital technologies such as IoT, AI, and robotics.

- Edge AI: The technology of building AI into Edge devices such as IoT devices and sensors, allowing the Edge devices to learn and infer. Inference and decision-making are performed within the Edge device based on data collected through the Edge.

- Mesh network: A communication network in which multiple relay devices in an equal relationship with each other form a mesh-like transmission path and transfer data by passing them around.