Our History

- TDK History

- Social events, history of electronics

-

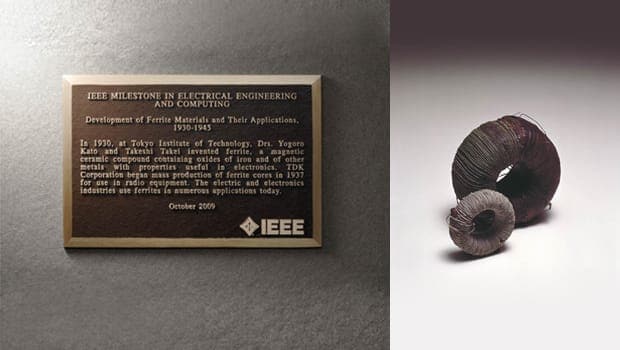

1930Invention of magnetic material "ferrite".

-

1931Invention of electron microscope. Charles Lindbergh successfully.

crossed the North Pacific by airplane. -

1935Development of radar. TV broadcasting started

in Germany.

With the objective of commercializing the world’s first ferrite core, Kenzo Saito, TDK’s first president, acquired the patent to ferrite from Dr. Yogoro Kato and Dr. Takeshi Takei and established Tokyo Denki Kagaku Kogyo K.K. in Tamura-cho, Shiba-ku, Tokyo City.

Bringing clear sound and pictures to people's homes.

The world's first application of ferrite as a ferrite core results in a dramatic reduction of noise.

Until about 1950, listening to the radio often was marred by noise and interference, and reception sensitivity was not very high.

But once ferrite cores came into use, the noise decreased and the sound became clearer, allowing more people

to listen and to obtain a wide range of information.

During the postwar economic growth period in Japan, the advent of television ushered in the age of visual information.

Ferrite from TDK was used extensively for the deflection

yoke cores in the CRT tubes of television sets which increasingly found their way into people's homes.

-

1937Kamata Plant constructed in Tokyo.

Ferrite core reaches the market under the

product name "Oxide Core." Production of color movies becomes widespread. -

1938Invention of magnetic sound recording system with AC biasing method.

-

1939Japanese Naval Institute of Technology

formally adopted ferrite cores

for use

with marine radio. -

1940Ferrite cores produced

in large numbers,

for use in mu-tuning

units of radios. Hirasawa Branch Plant

constructed in Hirasawa-cho,

Akita Prefecture. -

1945Kamata Plant burns down (April).

Ferrite production restarted (October, Hirasawa Plant). Computer with stored program proposed. Concept of communications satellite announced. -

1947Rapid rise in demand for IF

transformer cores for use in

superheterodyne type radio

receivers. Invention of the transistors. -

1951Black-and-white TV deflection

yoke cores reached the market. Production of standard-size cylindrical

type

ceramic capacitors started

at Hirasawa Plant. -

1953"Synchro Tape" brand of magnetic recording tape introduced. DNA double helix structure discovered.

-

1954World's first transistor

radios introduced. -

1955Disc-shaped

capacitors

"Ulcon"

introduced. -

1956Ichikawa Plant in Chiba Prefecture constructed. Development of hard disk drives.

-

1957World's first artificial satellite Sputnik

1 successfully launched by the Soviet Union. -

1958"Paramistor PM-4"

(parametron

arithmetic

element)

won the

Grand Prix at the

Brussels World

Exposition. -

1959Invention of integrated

circuits (ICs). -

1960TDK introduced its first barium

ferrite magnets. -

1961TDK listed on the First Section

of the Tokyo Stock Exchange. First manned space flight. -

1962Ferrite heads for magnetic drums introduced. Experimental TV satellite

broadcasting

carried out successfully. -

1966Introduced first

domestically produced

cassette tape.

(as OEM: June 1966,

as TDK brand: September 1966)

"Taking one's music along" creates a new lifestyle.

Cassette tapes designed specifically for music become immensely popular and make the TDK name known to the world.

Music on phonograph records or open-reel tapes required bulky equipment and therefore could only be enjoyed indoors, usually at home. Only after recording on the much more compact cassette tape became possible, people could take their favorite

music with them.

A living environment came to be filled with music anytime, anywhere.

In the latter half of the 1970s, video cassette recorders (VCRs) for home use came onto the market. Benefitting from its extensive experience

in audio cassette tapes, TDK began to mass-produce high-performance video cassette tapes.

-

1968TDK Taiwan Corporation established. Radio wave anechoic chambers introduced. First cassette tapes for music

recording "SD" launched in the USA. Liquid crystal displays

reached the market. -

1969Internet R&D began. Apollo 11 moon landing.

-

1970Glass-bonding

heads for

magnetic discs

introduced. -

1971Multilayer ceramic chip

capacitors introduced. Microprocessors introduced. -

1972Winchester heads developed.

-

1973High coercivity ferric oxide

material

"Avilyn" for

magnetic tapes developed. Oil crisis -

1974Switching power supplies

introduced. Samarium cobalt magnets

introduced. -

1976"AVISERT" automatic inserters for

printed circuit

boards with vertical

lead components introduced. VHS home video recorders introduced. -

1977Multilayer ceramic chip

capacitors used in

low-profile

portable radios. -

1978VHS and Betamax video

tape products released. Test-tube baby was born. -

1979Portable cassette tape players with headphones introduced. Cellular car phone services started.

-

1980Multilayer inductors introduced.

Ever smaller, and ever more capable. TDK drives the progress of home electronics.

Revolutionary multilayering technology leads the way towards smaller, thinner, and lighter home electronics.

After multilayer chip components came into use, home electronics suddenly became much smaller, thinner, and lighter.

Portable telephones which used to require a bulky shoulder-carried unit shrank into mobile phones easily held in one

hand.

Passport-size video cameras could be taken anywhere and brought the joy of watching videos to the general public.

And nowadays, all of these functions are usually integrated in a single smartphone.

-

1982TDK shares listed on the

New York Stock Exchange. Compact Disc players introduced. -

1983Company name changed to TDK Corporation. Home video game consoles introduced. World's first portable mobile phones.

-

1986SAE Magnetics (H.K.) Ltd., a magnetic recording

head manufacturing company based in Hong Kong,

joins the TDK Group. High-temperature

superconductivity discovered. -

1987Thin-film magnetic

heads introduced.

Making "a computer on

every desk" a reality

Thin-film magnetic heads enable building smaller computers with more data storage capacities.

In the early stages of the computer age, an electronic computer was a large-scale device for calculation assembled with advanced technologies. But programming required specialized knowledge and computer use was limited to a few experts.

After hard disk drives with high storage capacities were developed in the 1990s, more software such as spreadsheet or word processing programs, image processing software etc. could be installed on a single computer, and personal computers

became an indispensable part of most offices.

The rapid progress towards smaller and lighter hardware with higher storage led to the spread of notebook computers.

Sending email and documents via the Internet became common,

and computers can now be used anywhere by anyone.

-

1988Multilayer integrated device (MHD)

introduced. Giant magnetoresistance (GMR) effect

discovered. -

1989Fall of the Berlin Wall.

-

1990Technical Center in

Ichikawa,

Chiba

Prefecture

completed. Internet service

started. Hubble Space

Telescope launched. -

1992Recordable organic

dye film optical discs

(CD-Rs) introduced. -

1994TDK subsidiary established

in Xiamen, China. High-density recording

MR heads introduced. -

1995Personal

computers

became

widespread. -

1996Cloned sheep "Dolly" was born.

-

1997World's first hybrid cars introduced.

-

1998GMR heads introduced. Terrestrial digital TV

broadcasting started in the

United Kingdom. -

1999TMR heads developed successfully. European single currency Euro introduced.

-

2000Headway Technologies, Inc.,

a US-based magnetic head maker, joins the TDK Group. -

2001Digital audio players introduced.

-

2002System of corporate

officers introduced. -

2003Human genome

sequencing completed. -

2005PMR (perpendicular magnetic recording)

heads released. TDK Museum opened in Nikaho City, Akita Prefecture. Amperex Technology Ltd. (ATL),

polymer lithium battery manufacturing and sales, joins the TDK Group. Lambda Power Group including Densei Lambda,

development/manufacture/sales of power supply products, joins the TDK Group. -

2007Marketing and sales operations for TDK brand

recording media sold to Imation Corp.. Smartphone introduced in the USA, rapidly

gained popularity. -

2008EPCOS, a Germany-based electronic device manufacturer,

joins the TDK Group. Global economic crisis triggered

by Lehman Brothers collapse. -

2009"Development of Ferrite Materials and

Their Applications" recognized as

IEEE Milestone. -

2010Age of the

smart

society

arrived. -

2011TDK formulated TDK Environmental

Action 2020 Plan

(implemented from April 2011) World population exceeded seven billion. -

2012Dysprosium (Dy) free magnets developed.

-

2014TDK withdrew from the recording media

business. Ferrite selected as one of "Top 100

Innovations in Postwar Japan." World's first fuel cell vehicles

introduced. -

2015Age of IoT and AI arrived. Successful observation of

gravitational waves. -

2016TDK Environmental Vision 2035 established. TDK Museum reopened after renewal. Micronas Semiconductor Holding AG, a sensor maker,

joins the TDK Group. Hutchinson Technology Inc., a US-based maker of suspensions for HDD heads,

joins the TDK Group. Tronics Microsystems SA, an MEMS inertial sensor maker,

joins the TDK Group. -

2017Business alliance with Qualcomm and

the establishment of RF360 joint venture agreed. InvenSense, a US-based manufacturer

of inertial sensors, joins the TDK Group. ICsense, a Belgium based ASIC specialist,

joins the TDK Group. -

2019TDK Ventures established

as

a corporate

venture company. -

2020TDK joined the Responsible Business Alliance,

an initiative dedicated to corporate

social responsibility in global supply chains. COVID-19 became a global pandemic. -

2021Reinforcement of environmental

initiatives to achieve net-zero CO2 -

2022TDK joined the RE100,

an international environmental initiative. Business alliance formed by ATL and CATL and joint venture company established. Global population reached 8 billion. -

2023TDK started using 100% electricity derived from

renewable energy for operations

at all Japan manufacturing sites. Qeexo, Co, a leading developer of automated machine-learning platforms, joins the TDK Group. -

2024TDK SensEI Pte. Ltd, an AI venture established to

advance industrial machine health through edge AI and sensor fusion. -

2025SoftEye, Inc, a leading enabler of technologies

used in AI/Smart glasses, joins the TDK Group.

TDK will continue to use

its tech power

to make the

impossible available in daily life.

![]()

- A new type of radio triggers a sudden demand for ferrite.

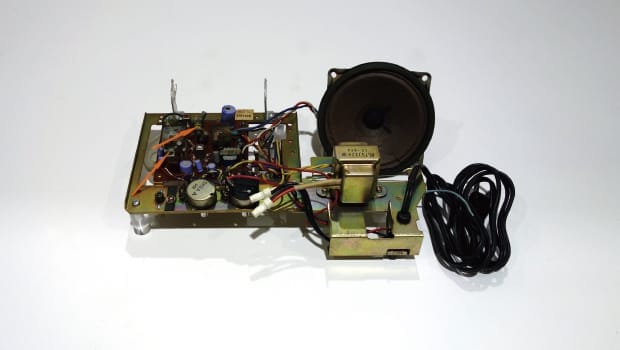

- In 1947, just after the end of WWII, the old type of radio (4-tube radios and similar) which suffered from noisy reception was replaced by a new principle called a superheterodyne receiver, offering much better performance. However, these receivers require an intermediate frequency transformer (IFT) that in turn needs a ferrite core, and orders for ferrite suddenly started pouring in at TDK, the only ferrite manufacturer in Japan at the time. This enabled TDK to overcome the difficulties of the postwar phase and build a solid foundation that lasts until this day. In 1955, Japan's first transistor radio hit the market. It was equipped with a bar antenna that used a ferrite core from TDK. In this way, TDK made a significant contribution in the field of radios which were the forerunners of today's wide range of audiovisual equipment.

![]()

- Ferrite demand jumps with launch of TV broadcasting.

- In 1950, as NHK (Japan's national public broadcasting organization) began experimental television broadcasting, TDK embarked on the research and development of prototype ferrite cores for the deflection yokes and flyback transformers necessary in order to display an image on a cathode-ray tube. The cores were finally ready for mass production in 1953, around the same time when regular TV broadcasting got under way in Japan. Some seven years later, color TV broadcasting was launched in 1960. In the 1980s, TV screens rapidly became much larger, driving the demand for more complex deflection yoke shapes and higher performance. Power ratings also increased, leading to an increase in demand for power ferrite materials to be used in transformers for switching type power supplies.

![]()

![]()

- 1955

- Disc-shaped

capacitors

"Ulcon"

released.

![]()

- 1958

- "Paramistor PM-4"

(parametron

arithmetic

element)

won the

Grand Prix at the

Brussels World

Exposition.

![]()

- 1966

- Launch of

first domestically produced

OEM cassette tape.

![]()

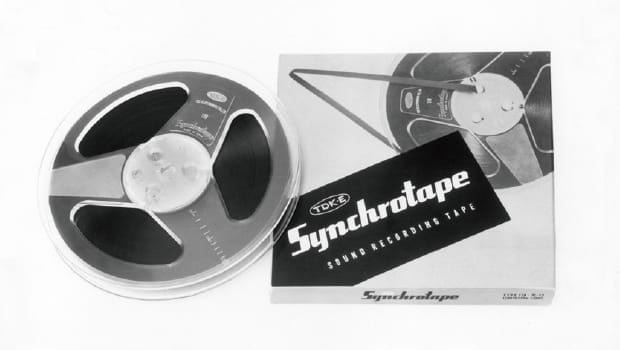

- Audio tape and video tape adopted by broadcasting stations

- In 1950, the year the first tape recorder made in Japan was introduced, TDK embarked on a research and development project for magnetic tape as a new business, harnessing the company's strength in magnetic materials technology. Three years later, in 1953, a magnetic tape product called "Synchrotape " for open reel tape recorders was launched. Ongoing research resulted in further refinements in terms of materials technology and manufacturing techniques. In recognition of its broadcast level performance, Synchrotape was adopted by broadcasting stations in 1957. Technical cooperation by TDK also was instrumental in the effort to develop a locally produced video tape. In 1963, the "Synchro Video Tape" developed by TDK was selected for use in broadcasting. At the Tokyo Olympics held in the following year, about 60 percent of the video tapes used for broadcasting applications were TDK products.

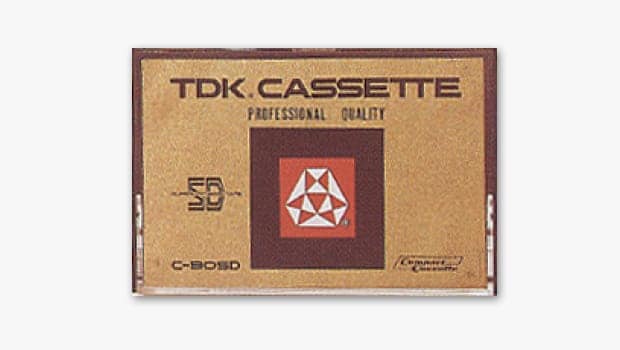

- SD cassette makes the TDK name famous worldwide.

- The wider a magnetic tape, and the faster its travel speed, the more information can be recorded on it. In 1966, TDK brought a cassette tape product called "Synchro Cassette" onto the market, but due to the narrow width of the tape and its slow speed as compared to open-reel tapes, the cassette was not suitable for music recording. In order to solve this problem, TDK developed a new type of magnetic powder with vastly improved characteristics, which made it possible in 1968 to present the world's first cassette tape for music recording, branded as the "SD Cassette". With a clever sales strategy also paying off, the SD Cassette took the market by storm and received overwhelming feedback from users around the world. It became a monumental product that cemented the name of TDK as the world's foremost magnetic tape manufacturer.

- Contributing to TDK's image and brand recognition

- The first video tape recorder (VTR) was introduced in the U.S. in 1956, but the extremely high sales price limited its appeal mainly to TV stations and similar. Followed by the open-reel type, the 1960s saw the introduction of cassette type video recorders (VCRs), and in the 1970s , two competing systems of more compact VCRs for household use were developed: Betamax and VHS. TDK had already been supplying video tape as an OEM (Original Equipment Manufacturer), but as VCRs gained in popularity, TDK released a video tape product under its own brand name in 1978. To meet increased production capacity needs, a new plant dedicated to video tapes was constructed at Mikumagawa (Hita City, Oita Pref.) in 1982. At the time, video tape accounted for more than half of the company's entire net sales. TV spots and other types of advertising provided a strong boost to TDK's name recognition and significantly lifted the company's brand image.

- A new technology for cobalt coating the needle-shaped magnetic powder

- The characteristics of the magnetic powder which is applied on the plastic base film have a vital influence on the performance of the magnetic tape. By employing a powder with extremely fine needle-shaped particles for the SD Cassette, TDK was able to break through the performance barrier of cassette tapes, making them a viable music recording medium for the first time. Moving towards further advancement, TDK perfected a new technology in 1973 for coating the surface of the needle-shaped particles with cobalt. This enabled outstanding characteristics significantly better than the chromium dioxide that was the standard for high-performance tapes at the time. The new magnetic powder called "Avilyn" became the basis for the entire range of "SA" (Super Avilyn) products for music and video. The excellent sound and image quality afforded by these tapes provided a major boost to the culture of audio and video recording.

![]()

![]()

- 1972

- Winchester heads developed.

![]()

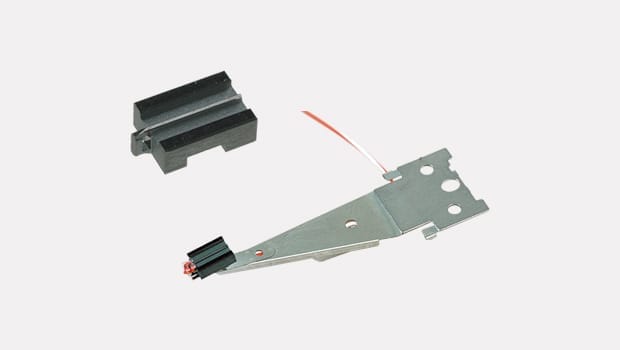

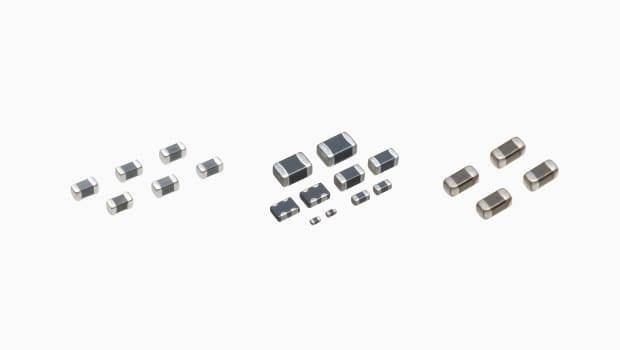

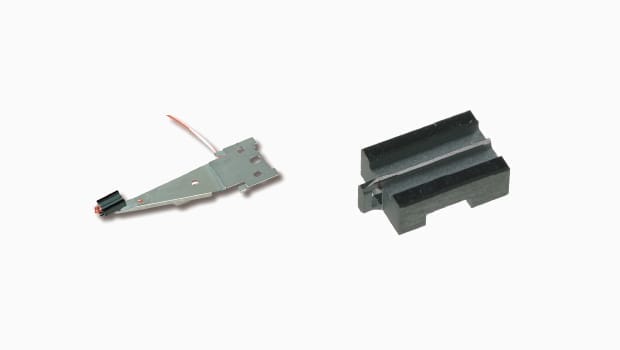

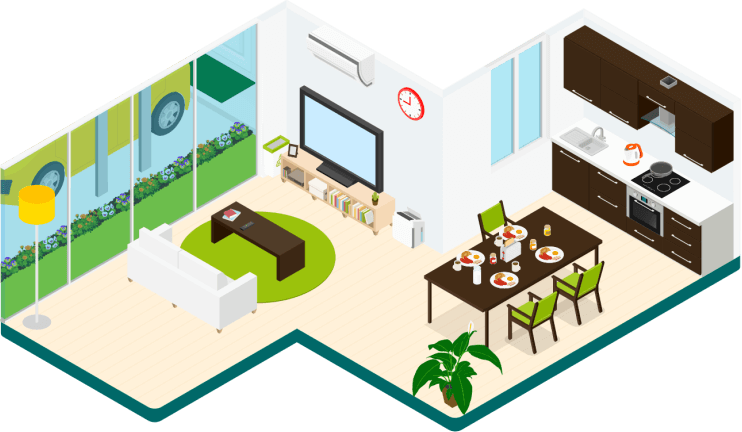

- Chip components and SMT (Surface Mount Technology) by automated placement equipment

- In the early days of electronics, most electronic components used to have long "legs" in the form of lead wires that were inserted into holes on the printed circuit board and then soldered to create a product. But in the 1970s a major innovation revolutionized the way in which electronic products were built. Very small chip-like components without lead wires are placed directly on the printed circuit board by high-speed automated pick-and-place equipment in a process that became known as SMT (Surface Mount Technology). An ultra-thin pocket radio that came onto the market in 1976 was the very first consumer product manufactured with SMT, and it featured multilayer ceramic chip capacitors from TDK. In the course of the next decade, chip components became ever smaller, triggering an amazing reduction in size and weight of electronic products.

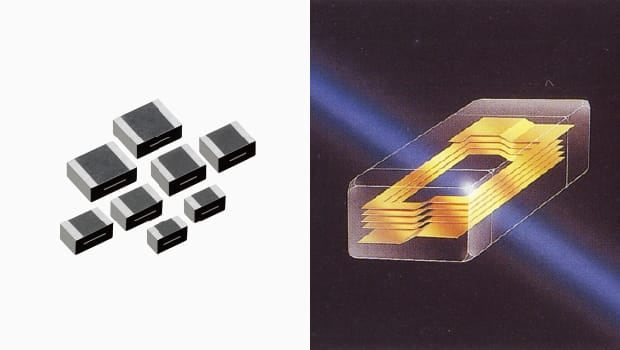

- Chip components realized with fine multilayer technology from TDK

- Inductors are normally made by winding coil wire around a magnetic core. But a breakthrough technology introduced by TDK in 1980 made it possible for the first time to form a coil by a layering process without winding, resulting in the world's first multilayer chip inductor reaching the market. TDK followed this up by "fine multilayering," a proprietary, highly advanced technique for simultaneous sintering of different materials such as ferrite and dielectric ceramics. Further development extended the technique to composite chip components integrating capacitor and inductor functions, and to a multilayer integrated device (MHD) comprising an IC. All of these greatly contributed to make portable electronic devices such as video cameras and personal music players much smaller and lighter while at the same time capable of higher performance.

![]()

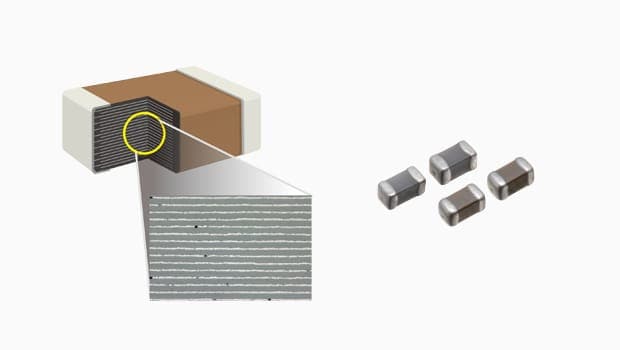

- Alternating dielectric sheet and internal electrode in layers

- Currently, more than 80% of all capacitors manufactured worldwide are multilayer ceramic chip types. A single smartphone or notebook computer may contain upwards of 500 of these. The world's first multilayer ceramic chip capacitor was developed in the U.S. in the 1940s, but it saw only limited use in special military or industrial applications. Only after mass production technology had been developed in Japan in the 1970s, multilayer ceramic chip capacitors found their way into consumer products in large numbers. There are many different variations and manufacturing methods, but the basic principle involves screen-printing of the internal electrodes on a dielectric sheet, layering the result, and then cutting it into individual chips.

- Applications include noise countermeasure components and circuit protection devices

- The availability of electronic components in chip format since the 1980s, along with the progress of SMT (surface mount technology) has greatly contributed to the realization of smaller, lighter, and higher functionality electronic equipment. TDK applied its original fine multilayering technology not only to capacitors and inductors but also to various other chip type products including noise countermeasure components and circuit protection devices. Turning electronic components into chips requires highly accurate screen printing techniques, advanced processing methods, and superior materials technology. Of utmost importance is a full mastery of the entire range of electroceramic materials which includes ferrite (magnetic ceramics), dielectric ceramics, and semiconductor ceramics.

![]()

![]()

![]()

![]()

- 1990

- Technical Center in

Ichikawa,

Chiba

Prefecture

completed.

![]()

- 1994

- TDK subsidiary established

in Xiamen, China.

![]()

- 2005

- TDK Museum opened in Nikaho City, Akita Prefecture

![]()

- 2009

- "Development of Ferrite Materials and

Their Applications" recognized as

IEEE Milestone.

![]()

- 2016

- TDK Museum reopened after extensive

renewal.