Sustainability | Governance | Supply Chain ManagementSustainable Procurement

Our Approach

TDK Group not only complies with laws and respects social norms but also fulfills social responsibilities such as respecting human rights and preserving the global environment, together with our business partners.

As an enterprise with a global range of manufacturing sites, the TDK Group stipulates the TDK Purchasing Policies to realize its Purchasing Principles and conducts purchasing activities in accordance with these principles.

"Global Partnership Purchasing" --- Purchasing Principles

TDK engages in global production with manufacturing sites in Japan, Asia, Europe and the Americas. Within the procurement activities that support production, the development of global procurement structures is crucial, and we strive to use those systems to develop products rapidly to remain competitive in the race to be first to market in the electronics industry.

Manufacturing sites engage in local procurement, but in today's society with ubiquitous IT networks, procurement activities require close collaboration with suppliers in ways that overcome time and distance. In addition, measures to fulfill corporate social responsibilities such as compliance with applicable laws and regulations, observance of social norms, and preservation of the global environment are promoted actively through partnerships between TDK and its suppliers.

Purchasing Policies

Compliance

All applicable laws and regulations are followed in purchasing activities. Moreover, TDK strives not only to follow the letter of the law, but its spirit as well.

Respect for Human Dignity

TDK respects the human dignity of workers who are active in all stages of the supply chain.

CSR

The procurement divisions of the TDK Group implement CSR activities on a continuous basis, while performing evaluations of suppliers at regular intervals using the CSR Check Sheet, to promote understanding of our CSR concept and raise recognition of our initiatives. In addition, as part of the common understanding of social issues, we have established the TDK Group Business Partner Code of Conduct.

Green Procurement

As one aspect of its companywide environmental protection activities and in the pursuit of harmony with the global environment, TDK engages in green procurement, i.e., the purchase of environment-conscious products.

Fair and Open Business

TDK conducts fair business regardless of company size or nationality. TDK bases its purchasing decisions on comprehensive evaluations of quality, price, delivery time, ability to provide a stable supply, and other factors.

TDK does not accept gifts of any kind from business partners.

As a general rule, TDK does not accept dining or other forms of entertainment from business partners.

Partnership

TDK seeks to build mutually beneficial relationships with suppliers based on shared goals.

VA*Activities

TDK values suppliers that can lower costs and provide new materials and technologies through VA activities.

IT Utilization

Information exchanges with suppliers using IT and networks are essential for accelerating the pace of business and reinforcing ties.

Quality, Delivery Time and Stable Supply

TDK always considers quality, delivery time and stable supply by establishing solid partnerships with its suppliers.

- VA (Value Analysis) is a concept developed by the GE Company in 1947. VA provides a method to increase the value of a product or service, specifically by analyzing various factors associated with the value relative to the minimum resources necessary to produce said product or service (its cost). TDK uses the terms VE (Value Engineering) and VA synonymously.

The TDK Group has established a TDK Group Business Partner Code of Conduct grounded in the Group's TDK Purchasing Policies. The Code of Conduct asks suppliers to comply with the code of behavior stipulated by the Responsible Business Alliance (RBA), and also specifies the Group's expectations for compliance in how suppliers conduct their operations, under several categories: labor, health and safety, environment, ethics, information security, trade control, management systems, and supply chain measures. Furthermore, we expect our suppliers to recognize the risks associated with CSR and to take human rights and safety into consideration in their activities in the supply chain, as well as to reduce the environmental load of their operations.When selecting suppliers, we will be proactively seeking to work with companies that have expressed their agreement with the TDK Group Business Partner Code of Conduct.

Governance

Within TDK Group, to fulfill social responsibility across the entire supply chain, the headquarters' materials function, business groups, and headquarters' HR education and CSR functions work collaboratively to promote activities. Progress on key themes is discussed and reported at monthly review meetings. Additionally, monthly reports are made to the Corporate Planning Department, which then provides an annual report to the Board of Directors.

TDK’s Sustainable Supply Chain Management

How this operates in practice is explained in the “Initiatives” section below.

Sustainable-procurement education

The procurement department has created an e-learning course titled "Sustainability and CSR" that is available to all team members (employees). This course aims to promote understanding of the importance of sustainable procurement among procurement stakeholders.

We have also established classes relating to sustainable procurement, with the aim of providing e-learning content that all team members can utilize. In addition, we invite instructors from third-party organizations to give lectures to help cultivate personnel able to perform on-site CSR audits on suppliers’ premises.

For those personnel working in procurement-related units, both in Japan and overseas, we have provided a webinar on data management for promoting the reduction of Scope 3 CO2 emissions. Those personnel who successfully complete this training are deemed to have demonstrated their ability to apply the skills required for their role.

Membership of the RBA

In February 2020, the TDK Group joined the Responsible Business Alliance (RBA), * the world’s largest industrial coalition dedicated to CSR in the global supply chain. Accordingly, the TDK Group made a commitment to society that it fully supports the RBA’s vision and mission and, in accordance with the RBA’s code of conduct (labor, health and safety, environment, ethics, management systems), will continuously improve the human rights of workers, health and safety, and the environment in the TDK Group and primary suppliers.

In accordance with the RBA standards, the TDK Group will endeavor to make continuous improvements in two stages, self-assessment and audit, depending on the transaction status with suppliers (primary production materials), sub-contractors, and worker dispatch and labor agencies and the nature of their business.

- RBA : The Responsible Business Alliance (RBA) is a global industrial coalition embracing over 200 companies dealing in electronics, retail, automobiles, and toys. It stipulates standards of conduct related to the improvement of industrial health and safety, the protection of human rights, consideration of the environment, and fulfillment of ethical responsibilities in the supply chain and calls on affiliated companies and their suppliers to practice these standards.

-

Vision:

A coalition of companies driving sustainable value for workers, the environment and business throughout the global supply chain. -

Mission:

Members, suppliers and stakeholders collaborate to improve working and environmental conditions and business performance through leading standards and practices.

Strategy

In response to the increasing expectations from stakeholders regarding accountability in supply chain management and changes in the external environment, such as the development of new standards and frameworks by public institutions and private organizations, the TDK Group has initiated new supply chain management efforts based on a new framework for material suppliers starting from FY March 2025. By using due diligence in the supply chain, we are aiming to realize the respect for human rights which forms part of TDK’s materiality. Through these initiatives, we will share information on environmental and human rights issues with our suppliers and promote awareness-raising activities together. To ensure that our purchasing practices do not impede suppliers' environmental and human rights initiatives, we prohibit placing orders with unreasonably short lead times or asking for unfair benefits, and we periodically discuss rising labor, raw material and energy costs.

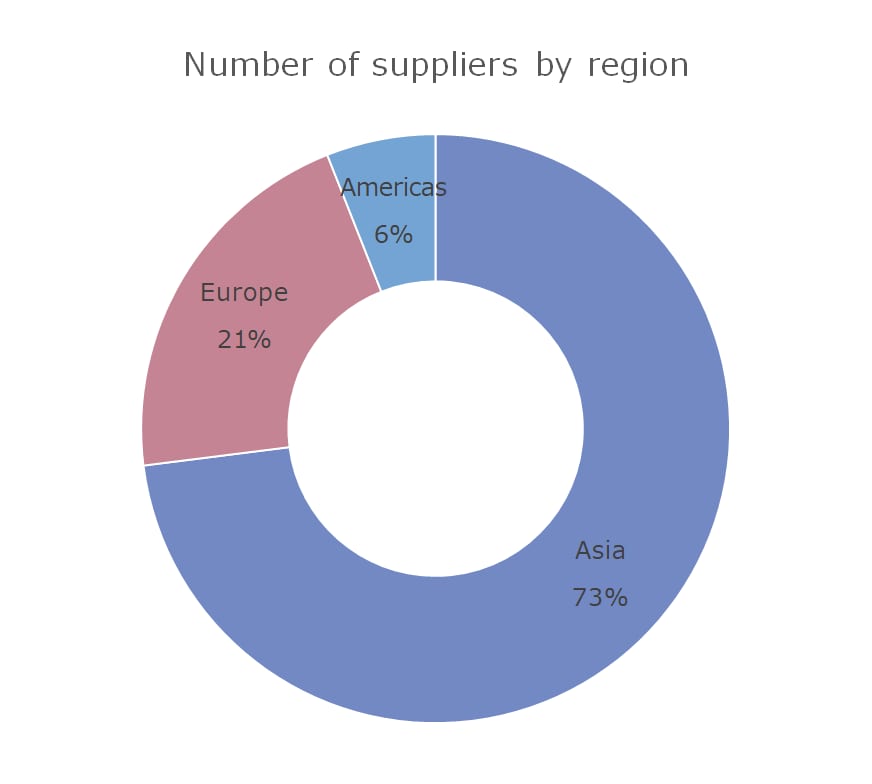

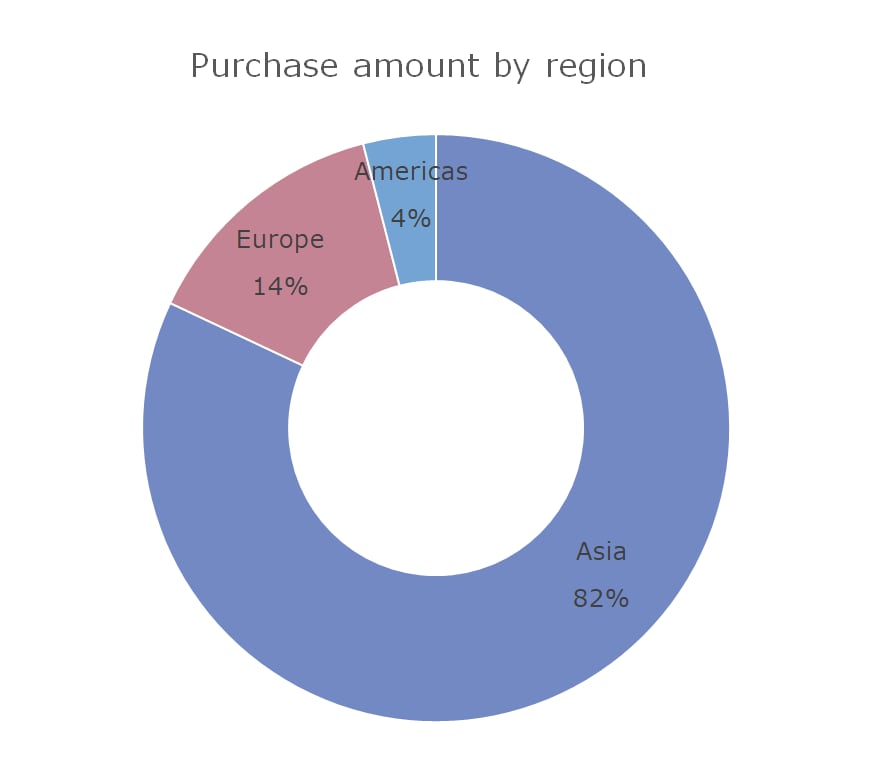

TDK Group Supply Chain

As of March 2025, TDK Group conducts business with approximately 3,900 material suppliers worldwide (excluding businesses from which we procure non-production materials such as office supplies and equipment), with an annual procurement amount of approximately 600 billion yen.

Risk Management

At TDK, we have established an Enterprise Risk Management (ERM) Committee to implement company-wide risk management activities. The ERM Committee analyzes and evaluates risks across the entire company, identifies risks that require countermeasures, and promotes enterprise-wide risk management by assigning risk owner departments to lead risk countermeasures. For individual risks, the assigned risk owner departments lead the implementation of risk countermeasures, and the committee monitors the status of these measures.

In the procurement area of ERM, risks such as "insufficient checks and monitoring of suppliers" and "unfair practices towards suppliers" are recognized.

The former is the risk of selecting suppliers that do not meet the standards of our company or are affiliated with anti-social forces due to inadequate supplier selection criteria and CSR checks. This could result in reputational damage or operational stoppages due to illegal activities by such suppliers.

The latter risk involves the potential for reputational damage to TDK through exposure by authorities, public disclosure of our company name, and media coverage due to making unreasonable demands on suppliers. To mitigate this risk, we are providing thorough education for our team members, including training on subcontracting laws.

Metrics and Targets

Medium- and Long-term Goals

To ensure that we respect human rights (which forms part of TDK’s materiality) in relation to suppliers, we perform CSR audits. If we discover any non-conformance that is particularly serious, we implement corrective measures and improvement activities.

Goals and Achievements in FY March 2025

| FY March 2025 Goals | Achievements |

|---|---|

| Percentage of key suppliers implementing self-checks (FY March 2025-2026) | 61% |

| Achieve 100% implementation of CSR self-checks at sub-contractors (FY March 2025-2026) | 32% |

| Achieve 100% implementation of CSR self-checks at labor agencies used by manufacturing sites in the high-risk countries in Asia | 100% |

Evaluations and Future Activities

We have maintained a supplier CSR conformity rate of 100%. Starting from 2024, we are implementing self-assessment for key suppliers every two years, with the first set of results due to be published towards the end of FY March 2026.

In FY March 2025, we achieved our goal of implementing on-site CSR surveys at 46 suppliers. In 2025, we planned to implement on-site CSR surveys at 50 suppliers.

| FY March 2026 Goals |

|---|

| Achieve CSR compliant supplier rate of 100% (FY March 2025-2026) |

| Achieve 100% implementation of CSR self-checks at sub-contractors (FY March 2025-2026) |

| Achieve 100% implementation of CSR self-checks at labor agencies used by manufacturing sites in the high-risk countries in Asia |

Initiatives

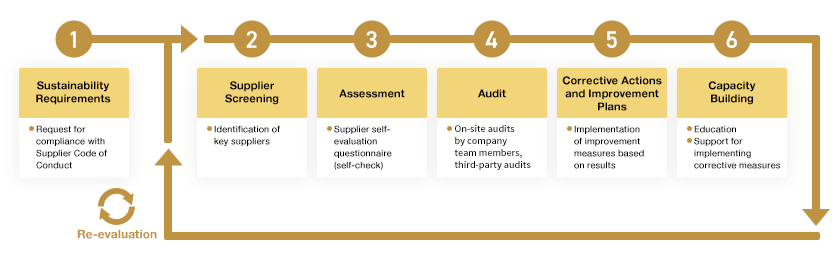

Sustainable Supply Chain Management Initiatives

(1) Sustainability Requirements

TDK Group communicates the sustainability requirements it expects all suppliers to comply with in their transactions by incorporating CSR-related clauses such as legal compliance, environmental conservation, prohibition of forced labor, respect for human rights, and product safety into their basic transaction agreements. In addition, we formulated the TDK Group Business Partner Code of Conduct in October 2024, establishing common requirements that all suppliers are expected to comply with.

(2) Supplier Screening

TDK Group identifies critical suppliers for each business, taking into account the following requirements:

- Suppliers with large purchase amounts

- Suppliers providing materials or components that are difficult to substitute

- Suppliers providing materials or components critical to the business

- Suppliers selected from an ESG perspective, etc.

As of March 2025, we have identified approximately 660 companies as key suppliers, accounting for 76% of the total annual purchase amount across the group. Additionally, we have identified 38 secondary and subsequent suppliers as key suppliers. The review of key suppliers is conducted annually.

(3) Assessment

TDK Group conducts CSR self-checks for all suppliers at the start of business relationships to confirm their CSR initiatives, and only begins transactions with companies that pass the evaluation. From 2024, we will conduct evaluations of critical suppliers in principle once every two years to determine whether to continue business relationships.

Regarding implementation methods, each company adopts appropriate techniques. However, the CSR self-check sheet created by the headquarters' procurement function consists of 63 items based on RBA standards, focusing on areas that TDK considers particularly important: "Human Rights and Labor," "Environment," "Safety and Health," "Fair Trade and Ethics," "Information Security," and "Management Systems." We request reports on management systems and implementation status for each item.

In FY March 2025, we conducted CSR self-checks on 1,417 companies (including 403 key suppliers) and confirmed that approximately 3,900 material suppliers (excluding non-production material suppliers such as office supplies) are CSR-compliant suppliers.

(4) Audit (5) Corrective Actions and Improvement Plans (6) Capacity Building

TDK conducts the CSR-specific on-site auditing of critical suppliers based on RBA auditing standards.

When violations of laws and regulations are discovered, we require suppliers to take “corrective actions” and monitor them from the development of corrective action plans to their completion. If necessary, we also provide support on implementation of corrective actions. If there are opportunities for improvement that do not result in legal violations, we make a "request for improvement".

In 2024, we implemented audits at approximately 70 companies in and outside Japan, and discovered two instances of non-conformity. Having discovered that one supplier was requiring employees to work excessively long hours, and that another was failing to provide health checkups for employees, we provided guidance to the suppliers in question, and got them to make changes to the relevant internal rules. We subsequently confirmed the status of implementation of corrective measures, verifying that the problems had been remedied.

For some audits, suppliers undergo RBA VAP audits conducted by third-party organizations and share the reports through RBA-Online, which helps improve efficiency.

Re-evaluation

As part of our series of initiatives, we terminate contracts with suppliers who are unable to meet minimum requirements within a specified period.

Supplier evaluations

In addition to CSR self-checks focused on CSR, the TDK Group conducts management system assessments of material suppliers at the time of new registration and periodically to ensure healthy transactions. These assessments determine whether to initiate or continue transactions. Each company adopts appropriate methods, and transactions are conducted only with companies that have no issues based on the assessment results.

The main categories covered by the evaluation are quality management, chemical substances*management, environmental management, and corporate social responsibility (CSR) including strict observation of human rights and other legal obligations as well as compliance with social norms. Any problems that come to light through the evaluation are disclosed to the supplier with a request for corrections or improvements.

- The chemical substances in the evaluation are based on the “TDK Green Procurement Standards.”

Related link

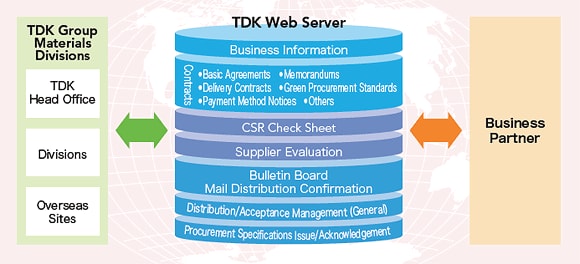

Supplier Partnership System

TDK requires its suppliers to reply to a CSR check sheet through the Supplier Partnership System. This Supplier Partnership System is a system by which the management of company information, distribution of purchase specification forms, sharing of agreement documents, and so on, which previously was conducted by paper or magnetic recording media, are managed uniformly online. It benefits both sides by speeding up and boosting the efficiency of work. To raise both supplier awareness and motivation to make improvements, the check sheet is designed to immediately display the results on-screen when answering questions. If problems occur with responses, individual requests are issued for improvements.

Green procurement

In order to promote green procurement aimed at prioritizing purchase of products that contribute to reducing the burden on the environmental and that fulfill social responsibility. TDK’s Green Procurement Standards are revised as necessary to take account of laws and regulations in Japan and other countries, changes in social requirements, and other factors. They can be viewed on the TDK website. In December 2024, we revised the annexes to the Standards, adding a number of new substances, including DP and UV-328, to the list of prohibited substances.

TDK’s procurement master provides links to data consistent with TDK’s green procurement standards, firmly controls the content of prohibited substances and chemical substances requiring content management, and discloses and provides information as necessary.

Responsible Raw Materials Procurement

In line with the TDK Group Occupational Health/Safety and Environmental Charter, we strive to reduce the burden on the environment, by reducing CO2 emissions, energy use, and water use throughout the product lifecycle, from procurement through development, manufacturing, delivery, and use to disposal. To promote these efforts, we have put in place a framework, under the supervision of the responsible director, to clarify roles and responsibilities in regard to environmental activities. These activities have positive spillover effects on suppliers throughout the value chain, on external contractors and other business partners, and on our customers. “Resources,” as defined in our basic policy for this area, includes raw materials.

For example, our procurement-related units have been collaborating with suppliers and other external stakeholders, and have succeeded in building the electronics industry’s first recycling system for reusing the PET film used in the production of multilayer ceramic chip capacitors (MLCCs).

We also perform risk assessment in relation to raw materials suppliers using CSR assessment, to verify that suppliers’ production processes do not have negative impacts on the environment or on society. If serious negative impacts on the environment or on society are identified, we arrange for corrective measures to be taken promptly and strive to address the problem and mitigate its impact, thereby contributing toward the realization of a sustainable society.

Strengthening of BCP/BCM in the supply chain

In unforeseen circumstances, such as the outbreak of a large-scale natural disaster, TDK, as a member of the supply chain, has a duty to share social responsibility with suppliers and meet demands so as to ensure the stable supply of products required by customers.

Recognizing that the securing of stable supplies is an important responsibility, TDK addresses this issue in three main ways:

- BCP/BCM surveys of suppliers

- Advance collection and arrangement of information to use in an emergency

- Prompt initial responses using a BCP Confirmation System

In particular, regarding BCP/BCM surveys of suppliers, a joint industrial initiative has begun, and TDK implements the supplier BCP/BCM surveys utilizing the Supply-Chain Business Continuity Questionnaire of the Japan Electronics and Information Technology Industries Association (JEITA). Furthermore, TDK endeavors to strengthen supply chain BCP/BCM by, among other activities, holding BCP/BCM seminars for business partners. Additionally, we send individual feedback sheets to each company to encourage improvement.

Strengthening of compliance (TDK Corporation)

TDK has clarified a company-wide policy regarding offers of gifts and entertainment from suppliers, publicized that policy throughout the Group, and requested the understanding and cooperation of suppliers.

Furthermore, regarding the exclusion of antisocial forces, TDK conducts preliminary surveys of suppliers when starting or restarting business with them.

Supplier Education and Capacity Building

TDK organizes seminars and offers individual support on several CSR-related topics with the aim of strengthening the initiatives of our suppliers.

- Individual support to strengthen information security at suppliers and contract manufacturers has been provided to several dozen companies, with support continuing for several months for each company. In this way, we have been able to ensure that these companies have the technology in place to make them more resilient to cyber-attacks.

- TDK also conducts surveys of suppliers’ environmental initiatives to reduce CO2 emissions, etc. Based on the results obtained in these surveys, we have for five years now been holding supplier award activities and providing feedback on the survey results. This feedback includes not only the assessment results, but also information on where each company’s performance stands within its peer group. We have also been arranging for lecturers from CDP to provide webinars for a total of approximately 150 companies to explain the CDP Supply Chain Program. Additionally, we conducted on-site energy-saving diagnostics for several suppliers, offering advice on how to reduce electricity consumption. These activities have been recognized, with TDK receiving an A rating in the CDP Supplier Engagement Assessment for five consecutive years.

Declaration of Partnership Building

In May 2021 TDK issued its "Declaration of Partnership Building" as a means of building relationships of coexistence and co-prosperity with its suppliers. "Declaration of Partnership Building," used as a general term, is an initiative launched by the Council on Promoting Partnership Building for Cultivating the Future, whose membership consists of the chairman of the Japan Business Federation (Keidanren); the chairman of the Japan Chamber of Commerce and Industry; the president of the Japanese Trade Union Confederation; the Minister of State for Economic and Fiscal Policy ; the Minister of Economy, Trade and Industry; the Minister of Health, Labour and Welfare; the Minister of Agriculture, Forestry and Fisheries; and the Minister of Land, Infrastructure, Transport and Tourism. Each participating company issues its own declaration under the name of a corporate representative, the aim of each declaration being to build new partnerships by promoting cooperation, co-existence, and co-prosperity between the issuing company and its suppliers and other business partners seeking to create added value. A company issuing a declaration states that it will seek coexistence and co-prosperity across its supply chain, promote new forms of cooperation irrespective of such factors as size or relationship to the supply chain, and observe appropriate transaction practices between main subcontracting entrepreneurs and subcontractors, all in an effort to boost the added value of the entire supply chain.

Concern for Human Rights in Relation to Employees of Suppliers (Including Contract Manufacturers and Staffing Agencies

Initiatives Targeting Materials Suppliers

As part of our promotion of CSR-aware procurement, we implement CSR self-checking (based on the items required by the RBA) within the supplier approval process. In principle, self-checking is performed by all suppliers when TDK first starts doing business with them, and starting from FY March 2025, in the case of key suppliers, it continues to be implemented once every two years after that. The self-check items include items relating to human rights aspects of labor affairs, health & safety, and other human rights related matters. We also implement on-site CSR audits, selecting audit recipients in light of the importance of the products that they supply, TDK’s degree of dependence on them, etc.

Regarding the CSR self-check results for materials suppliers to TDK Group companies in FY March 2025, the CSR-compliant supplier rate (based on verification since beginning to do business with that supplier) was 100%, meeting our target.

Initiatives for Suppliers Other Than Material Suppliers

CSR Self-Check and Audits for Contract Manufacturers

For contract manufacturing companies, we conduct CSR self-checks based on RBA criteria, similar to our material suppliers. We set ourselves the target of assessing all of our contract manufacturers over the two-year period from FY March 2025 to 2026; in FY March 2025, the first year of implementation, assessment was performed for 32% of contract manufacturers.

In the case of contract manufacturers that are highly dependent on TDK, we also implement CSR audits, based on the RBA standards. In FY March 2025, we implemented CSR audits for three companies in Japan and one company overseas.

CSR Self-Check for Staffing and Employment Agencies

Regarding worker dispatch and labor agencies, it was recognized that inappropriate responses in such agencies were an issue in certain countries in Asia where risks relating to human rights and recruitment are thought to be high. For this reason, the CSR self-check is implemented every year for labor agencies used by manufacturing sites in high-risk countries in Asia, excluding Japan. With the aim of confirming management control relating to human rights and ethics, the self-check list consists of specified content related to the prohibition of forced labor, prevention of child labor, humane treatment and elimination of discrimination, fair wages and working hours; prevention of corruption and ethical violations; prevention of information leakage and risk avoidance; etc. In FY March 2025, self-checks were conducted at all 60 targeted labor agencies (100%). Regarding agencies that failed to achieve a certain level of results in the survey, the manufacturing sites using those agencies carry out improvements.

Holding of the Supplier Sustainability Summit (SSS)

TDK has held its first sustainability event for suppliers. The Supplier Sustainability Summit (SSS) was held to explain to suppliers TDK’s goals and requirements in relation to sustainability, supply chain resiliency, information security, and CSR, and as a venue for appealing to suppliers to work together with TDK in these areas. The SSS was held online on a global scale, with representatives of approximately 140 of TDK’s key suppliers taking part (182 individual participants from 22 countries).