Our Technology

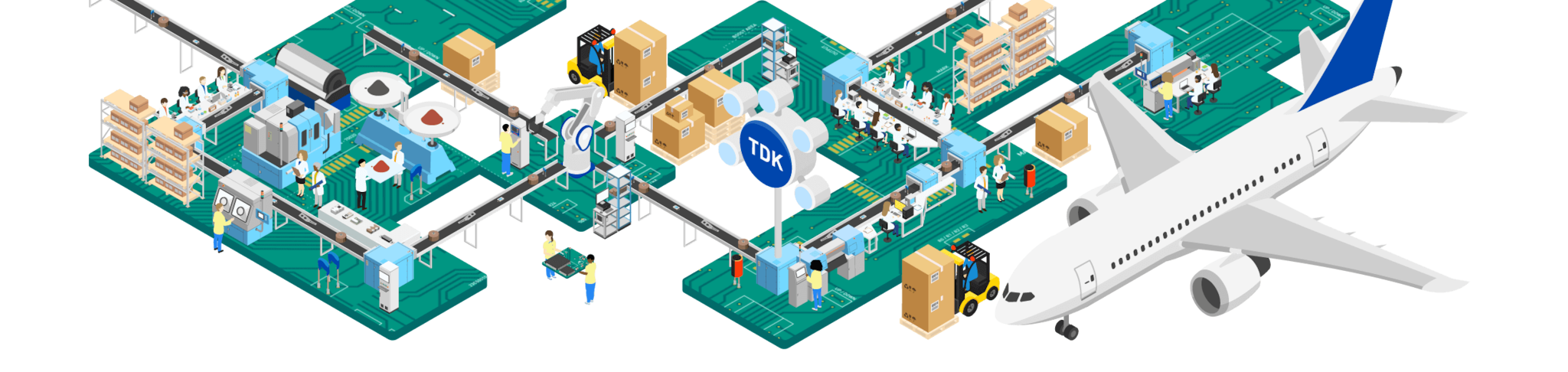

TDK was established in 1935 for the purpose of commercializing ferrite, a previously unknown magnetic material. Since then, TDK has used exceptional materials technologies and process technologies that maximally leverage the characteristics of materials to create innovative products from the ground up and support the development of the global electronics industry. Here, we introduce three key terms that support TDK’s Monozukuri (manufacturing excellence) : five core technologies, four great innovations, and Ferrite Tree.

-

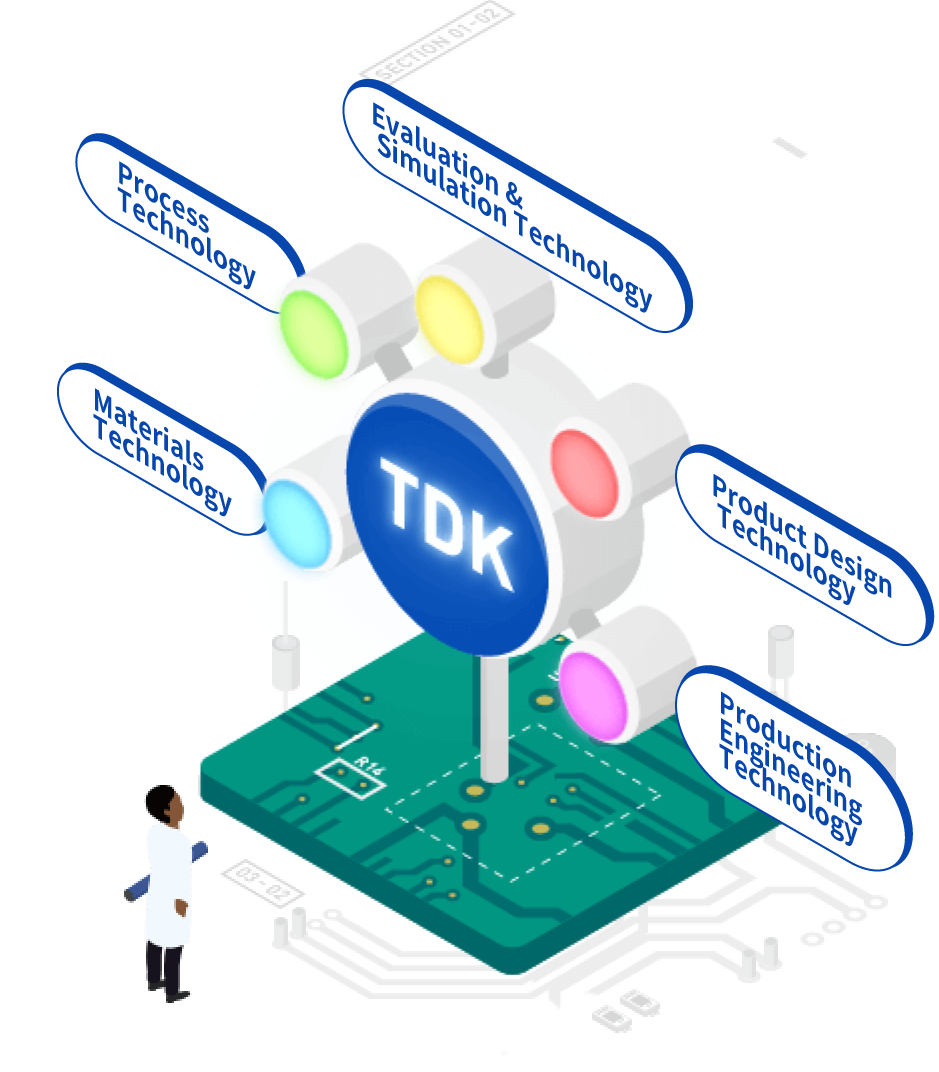

A description of five technologies that form the basis for the creation of cutting-edge electronic components, including materials technologies and process technologies.

-

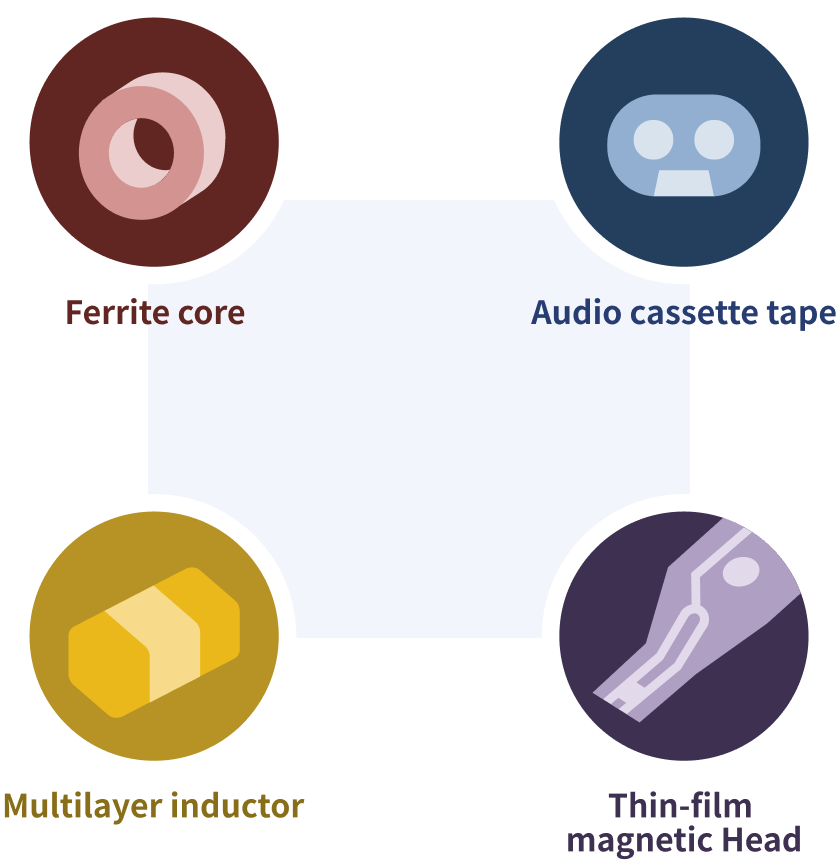

An introduction of four technologies created by TDK that have had significant impact on society: ferrite cores, music cassette tapes, multilayer inductors, and thin-film magnetic heads.

-

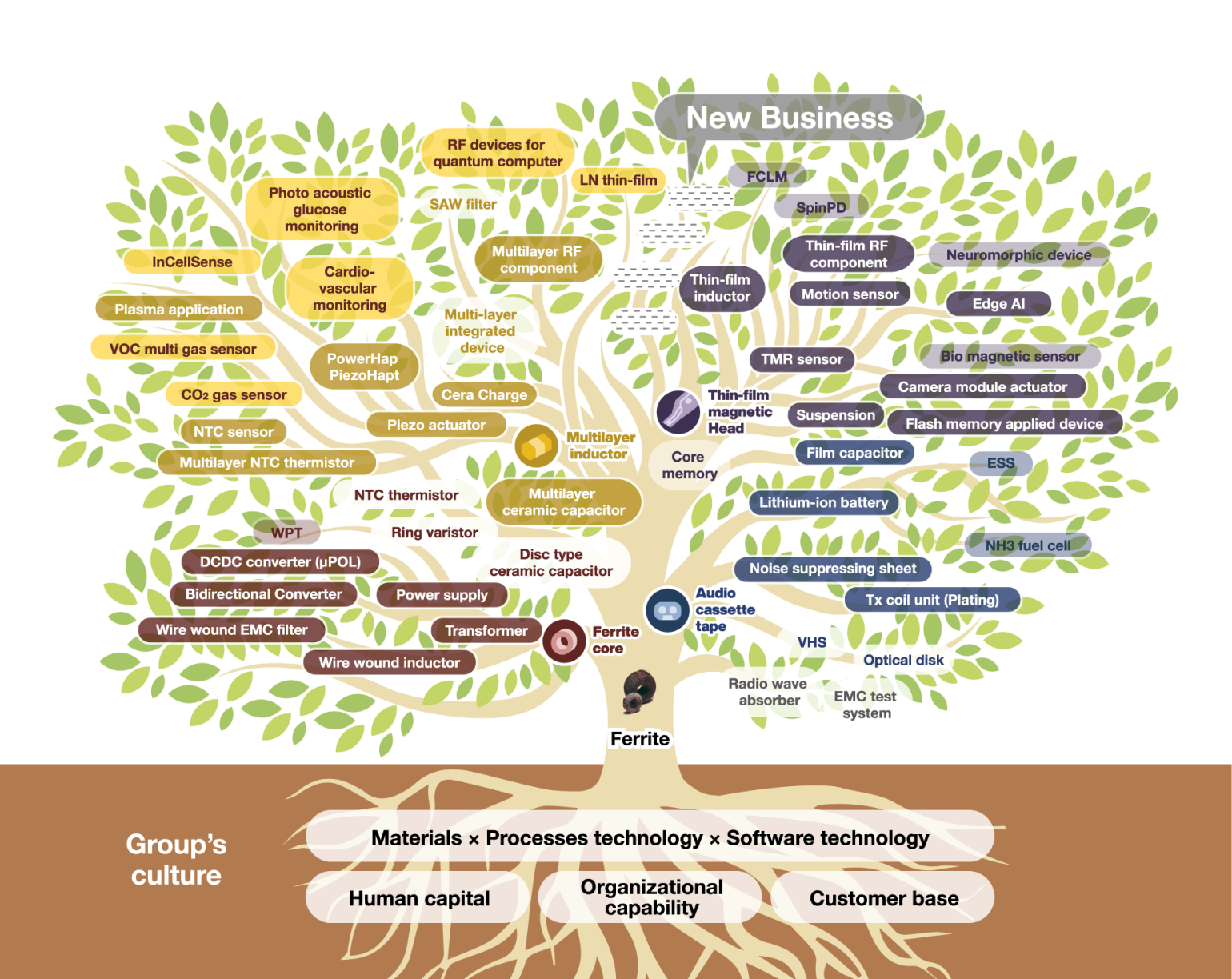

The Ferrite Tree represents TDK’s technological connections and business growth trajectory starting with ferrite, a magnetic material.

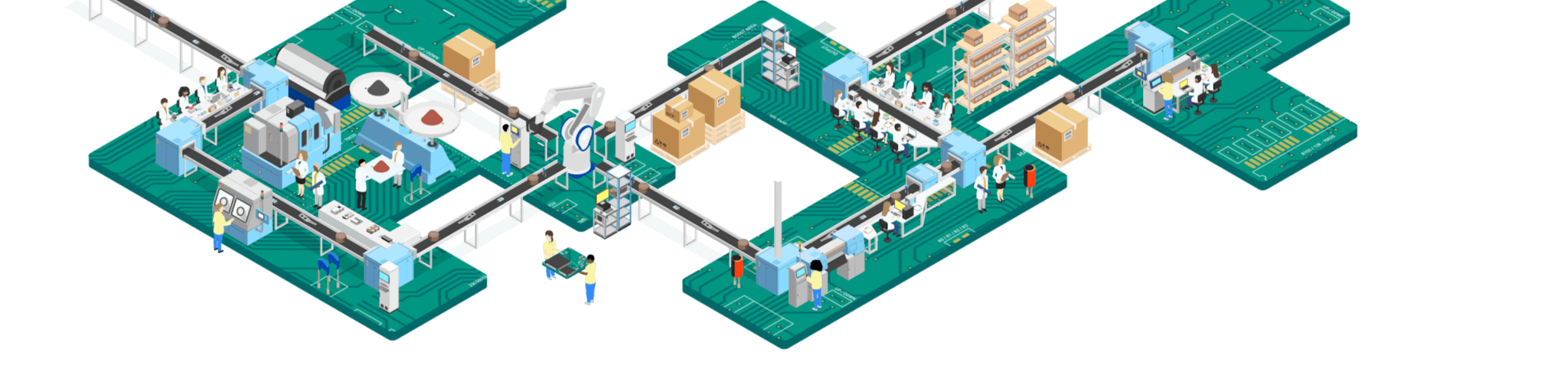

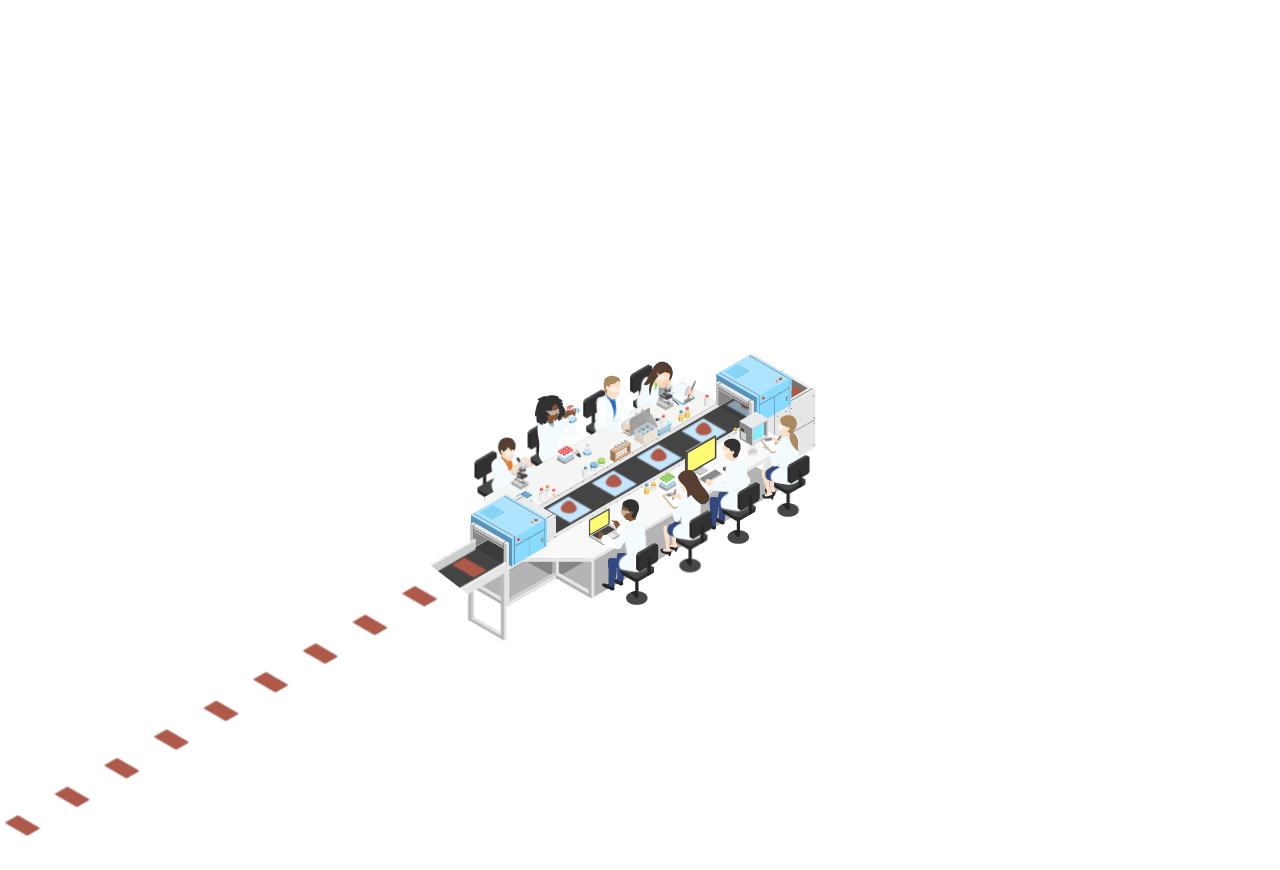

TDK’s Monozukuri starts with an understanding of materials

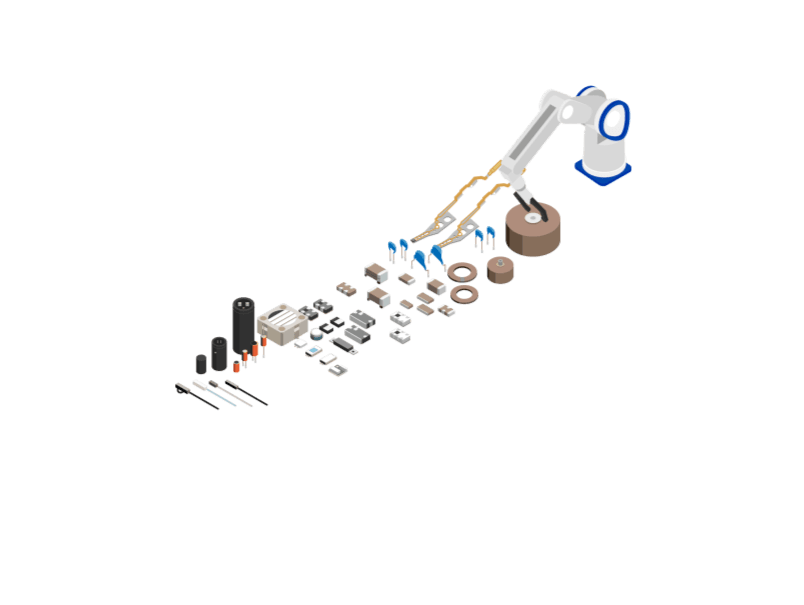

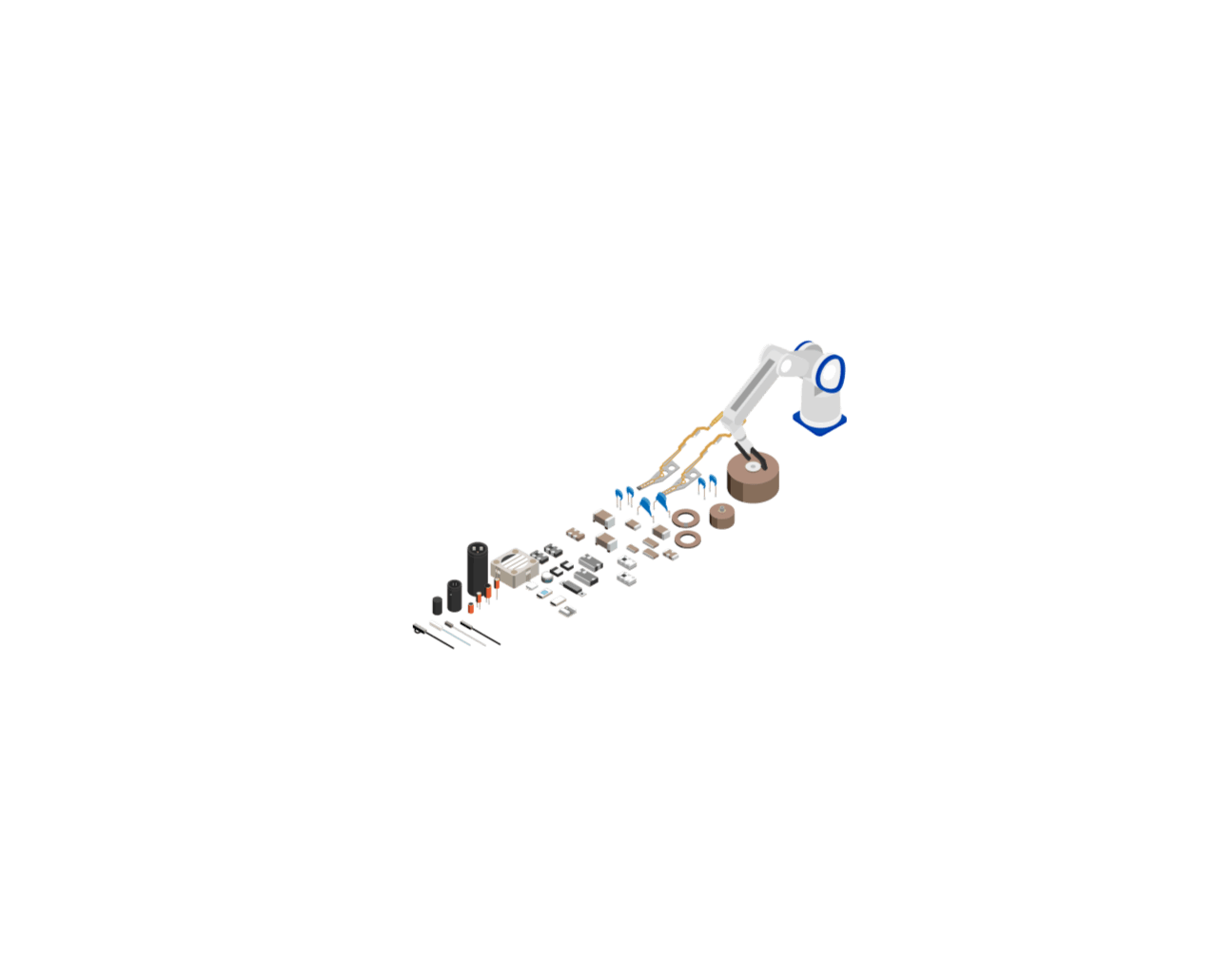

The key feature of TDK’s technology is in-house development starting from materials to create original electronic components from the ground up.

This is proof of TDK’s profound understanding of the characteristics of materials.

In addition, TDK boasts world-leading technological capabilities to create high-precision, ultra-compact components.

This is something that we can do because we are TDK, and something that only TDK can do.

Five core technologies

Five core competences for

producing cutting-edge

electronic components.

Manufacturing ferrite and other magnetic materials is where TDK has its origins. Over time, the company has added multilayering of electronic components, thin-film techniques, and spintronics (the control of individual electrons) to its roster.

Furthermore, TDK has harnessed a wide range of nanotechnologies in the quest to further expand the potential of magnetics.

Multifaceted advances are born out of these five core competences.

Materials technologyAccumulating more than 85 years of know-how and history.

TDK’s materials technology pursues the characteristics of the source material from the atomic level on up to meet highly sophisticated needs.

For example, materials design is based on carefully controlled ratios of the primary material and minute additives to precisely achieve the required properties on a high level.

A wealth of research and extensive experience accumulated over a period of more than 85 years makes this possible.

TDK outdistances competitors on the strength of its proprietary technological power.

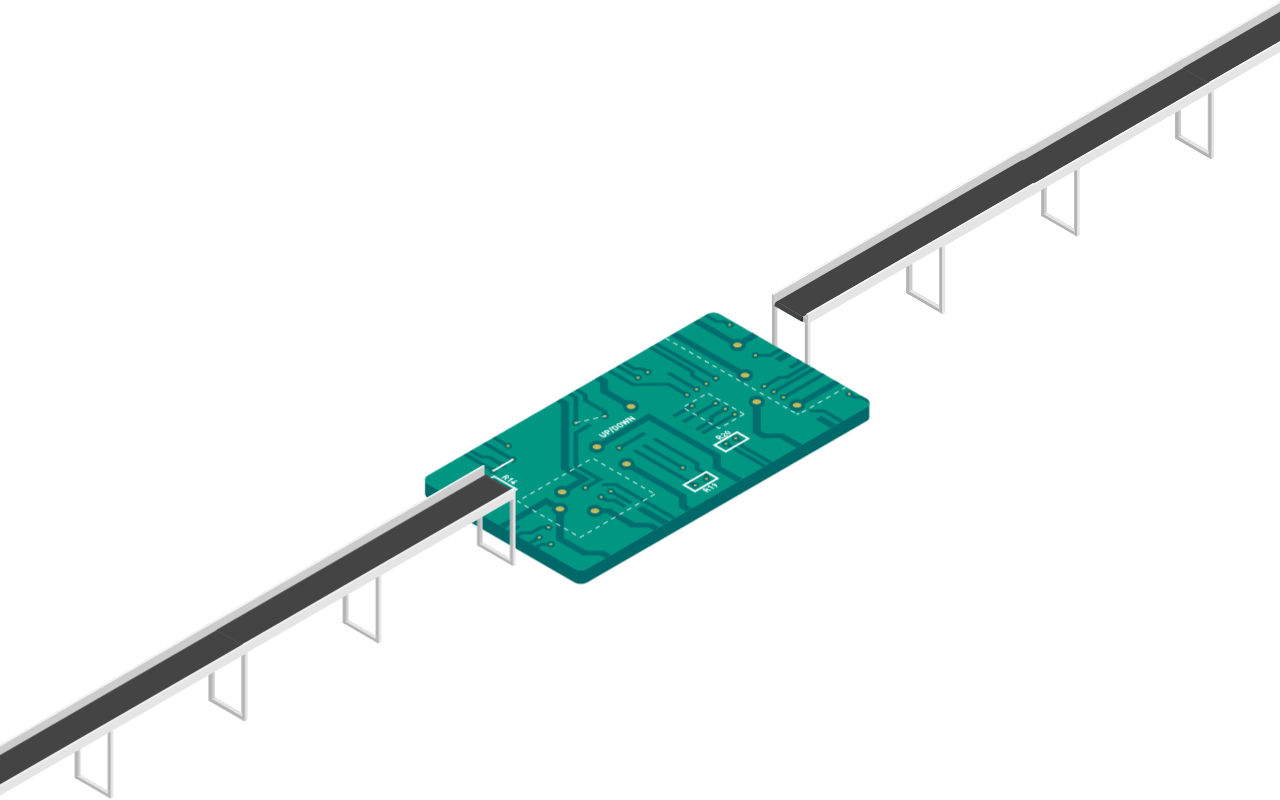

Process technologyRealizing control on the nanometer level.

Process technology is the science of getting the best out of the characteristics of the material.

Thin-film technology and spintronics are just two examples where manipulation on the order of nanometers (one billionth of a meter) is employed to create state-of-the-art electronic components.

An example is the creation of a thin film on a wafer to form an electrode, coil, or head element.

The method is applied to HDD heads, thin-film components and other products.

Evaluation and simulation technologyAccurately analyzing the ultra-fine aspects of a process.

Even the most advanced materials and process technology would not lead to successful product development without accurate analysis and simulation techniques.

Starting from material analysis, TDK evaluation and simulation technology is widely applied to assess structural and thermal aspects, analyze electromagnetic field properties, and perform noise measurement and design noise countermeasures using an anechoic chamber.

Ultra-precise methods are needed for evaluating ultra-fine technology.

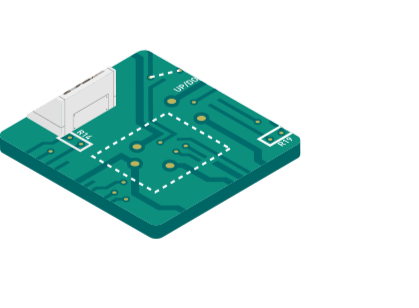

Product design technologyProduct design technology combines expertise with innovation to create new ideas.

Product design uses insight into how our products are used, integrating materials and electronic components from our many product lines, to create electronic devices and modules with safe, optimal configurations. It also encompasses software design that harnesses the full features of those devices and modules.

Additionally, TDK supplies energy units which combine power conversion, storage, and energy control functions. These integrated solutions have quickly become crucial for life in a sustainable society.

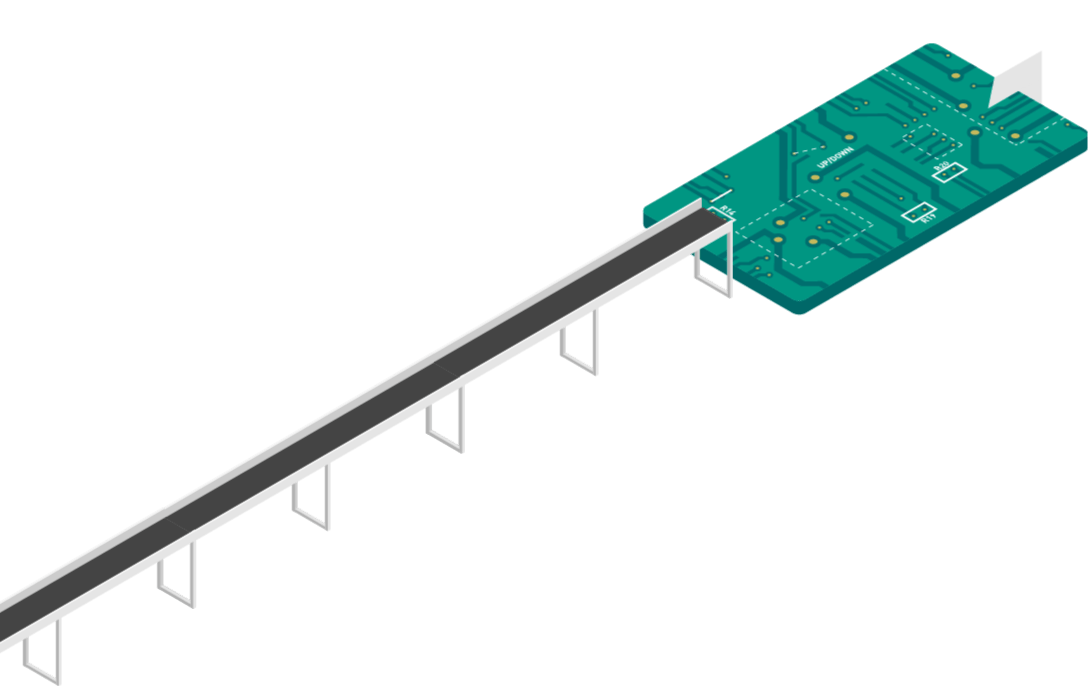

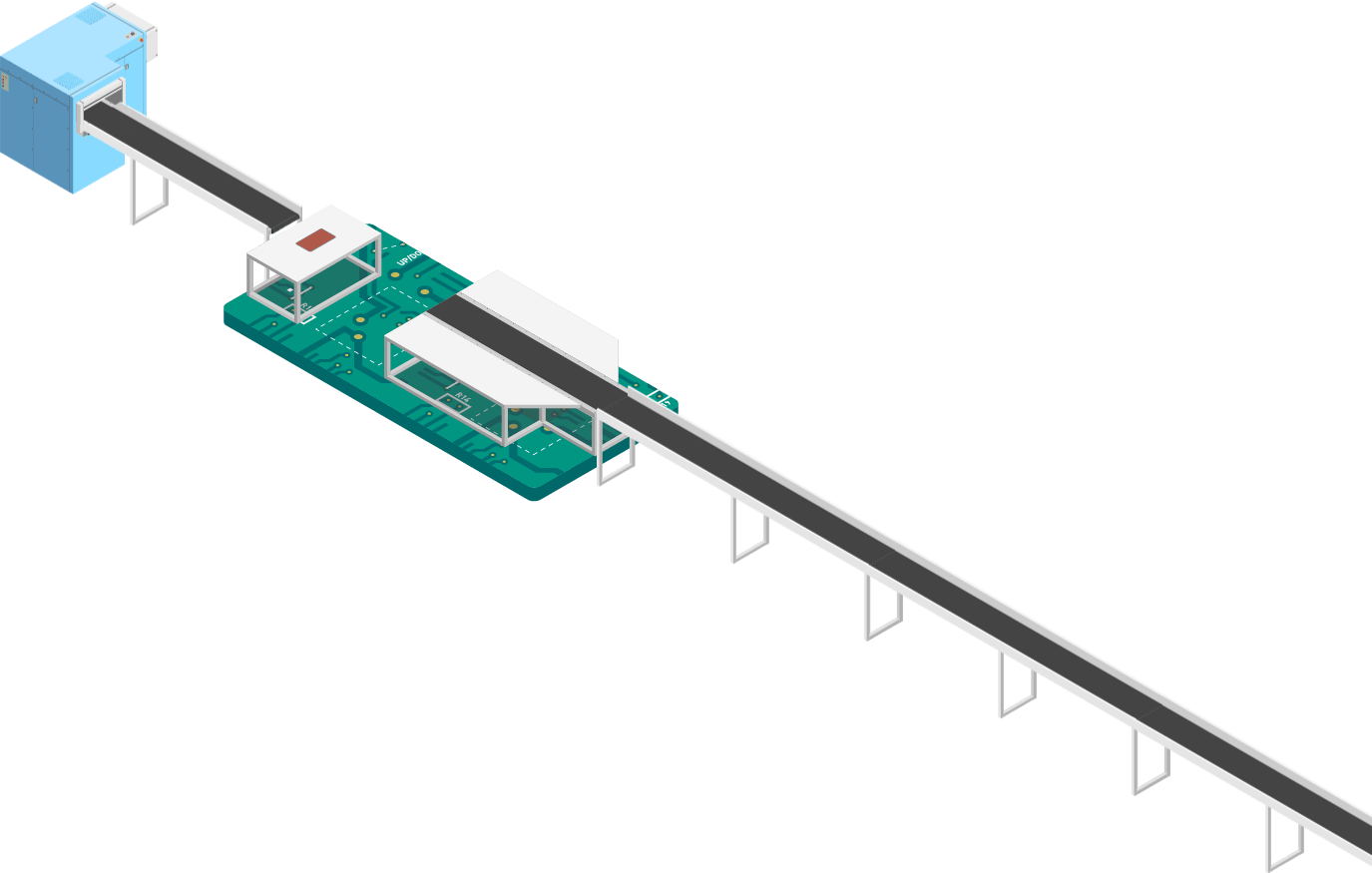

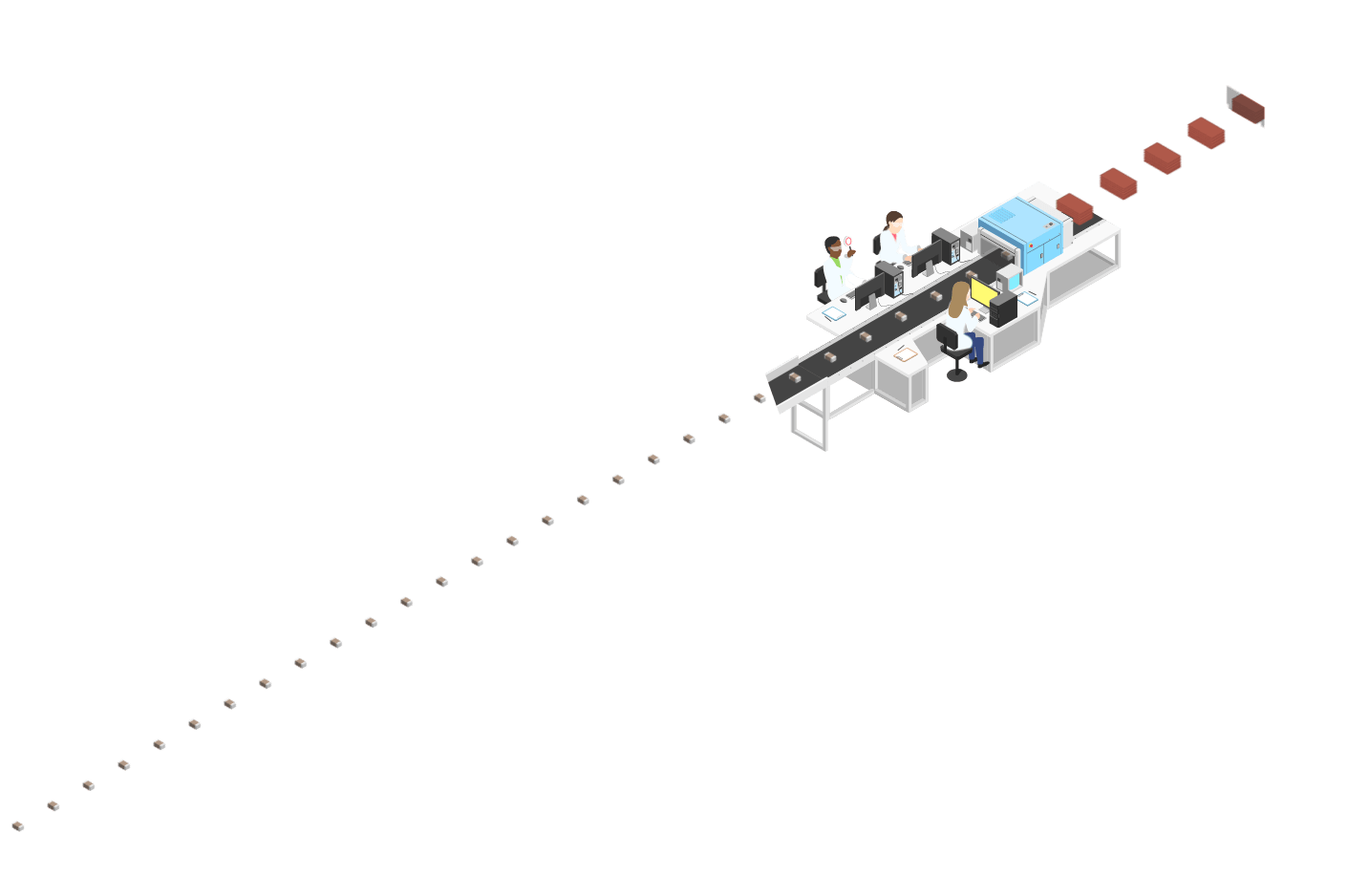

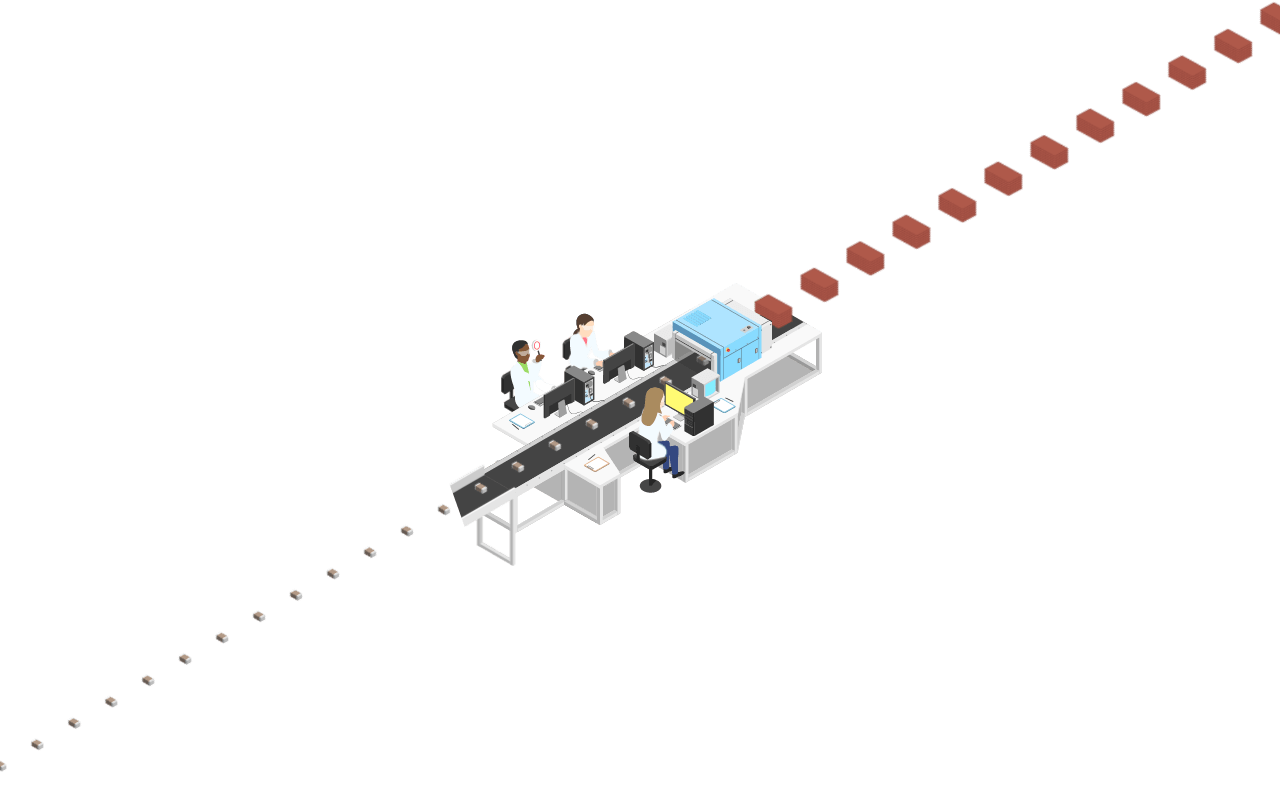

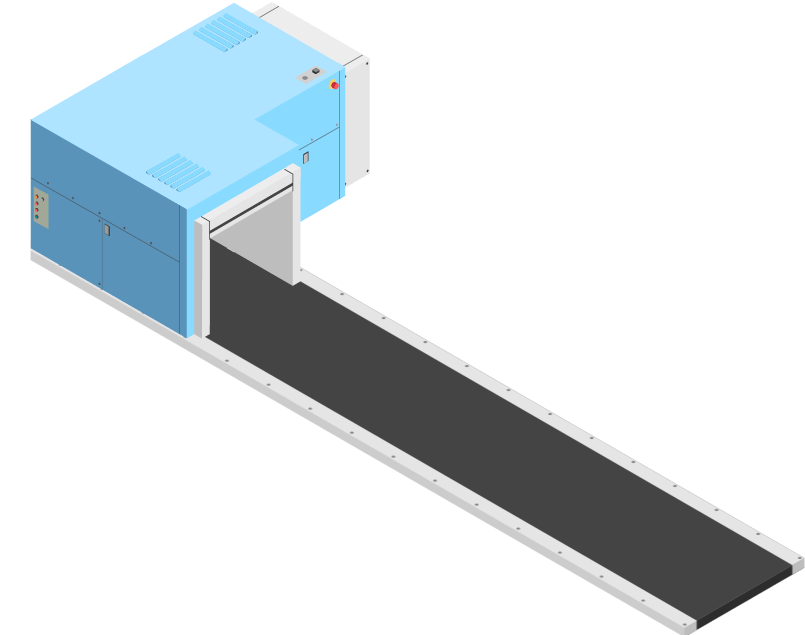

Production engineering technologyBuilding even the manufacturing equipment in-house.

Excellent products can only come from excellent manufacturing facilities.

TDK not only develops innovative manufacturing techniques but realizes these by building much of the required equipment in-house. This is the key to the superior Monozukuri craftsmanship for which TDK is famous.

The TDK policy of QCD (Quality, Cost, Delivery) is being further strengthened to create a system of integrated production extending from source material to finished product.

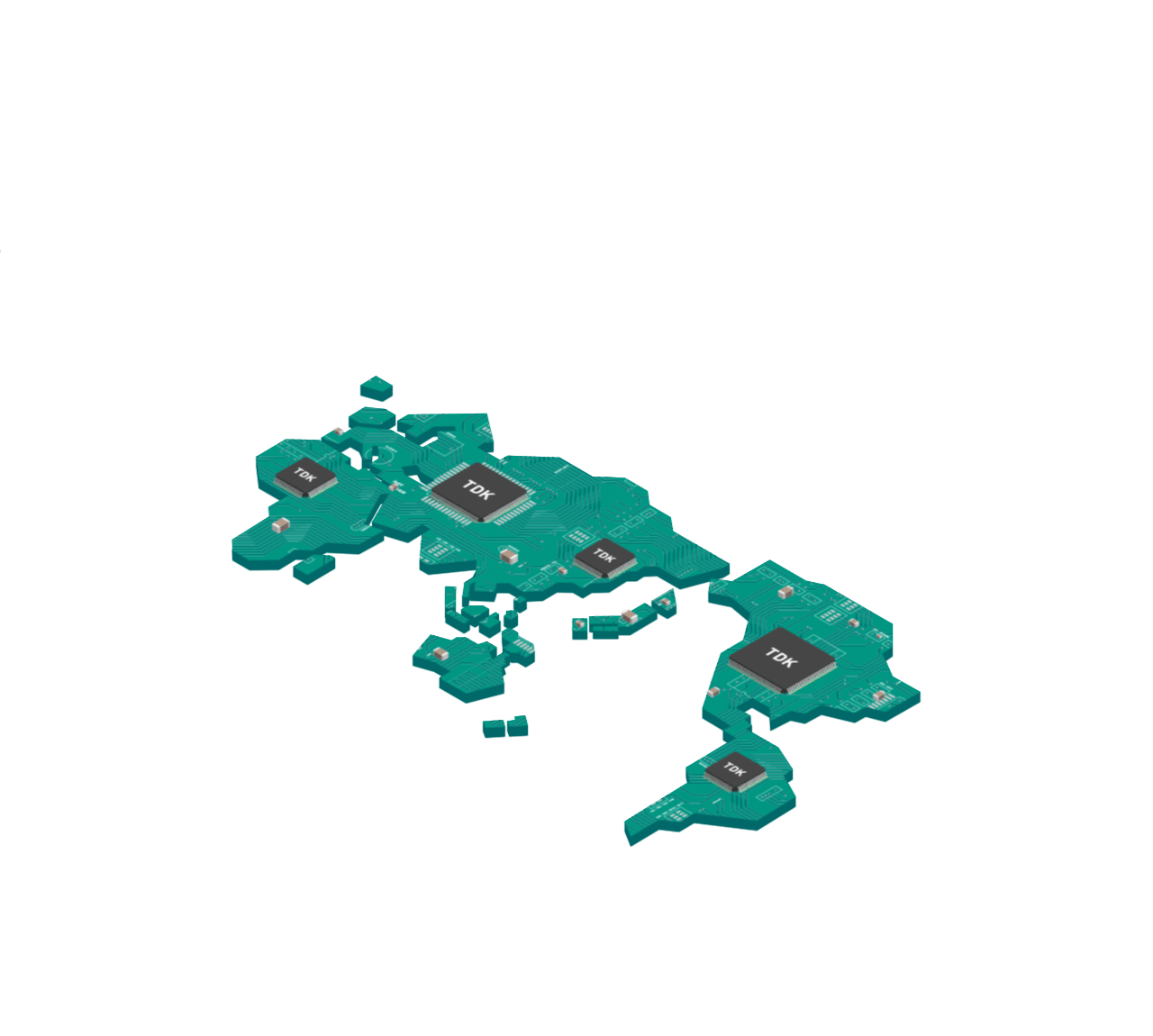

Realizing the same outstanding quality regardless of location.

That is what TDK tech power means.

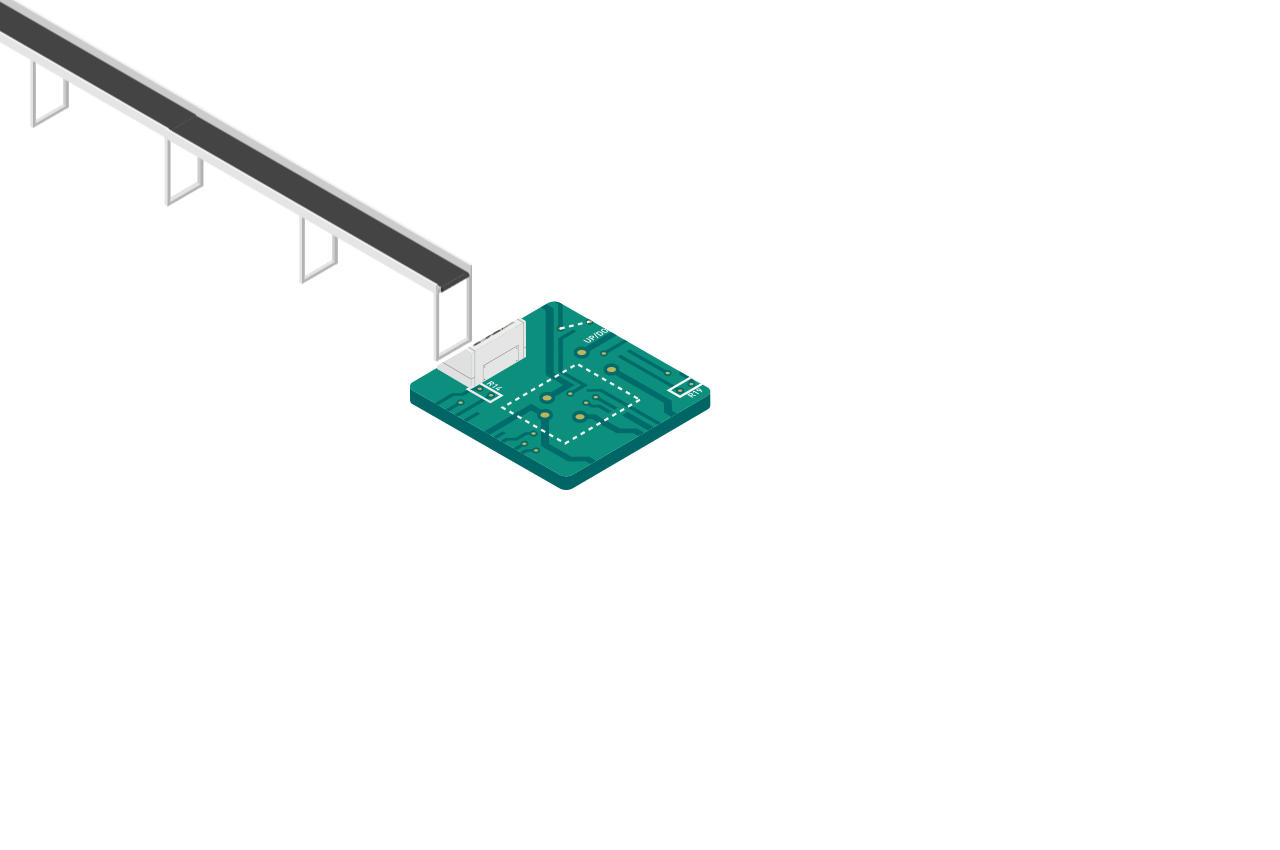

TDK is aiming for a unified Monozukuri standard. This involves the realization of a "location-free" concept whereby products of exactly the same quality level can be manufactured at any of our sites around the globe.

Building upon our expertise in mechatronics gained through the manufacture of electronic components, TDK supplies load ports for various wafer sizes and flip-chip bonders as well as various other advanced factory automation equipment.

Industrial robots and the production line itself are equipped with a multitude of TDK sensors that enable management of production status and quality in real time.

The collected data are analyzed in the cloud, making it possible to eliminate non-conformances and predict and avert possible breakdowns.

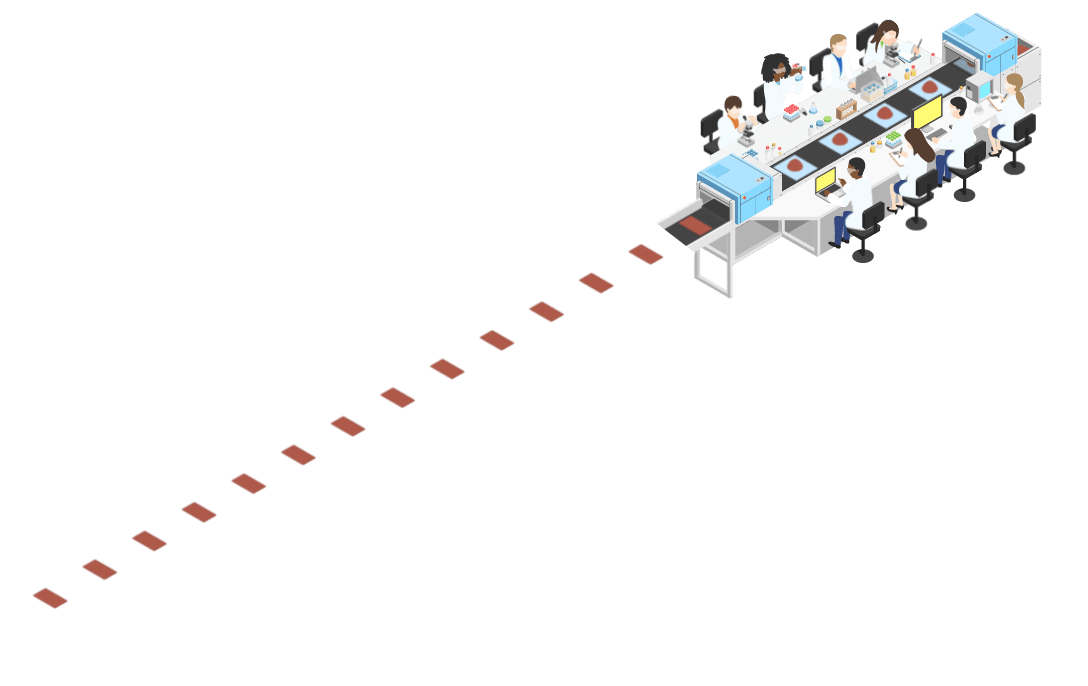

Four great innovations

For inventions that have had a significant impact on society

We refer to the four revolutionary products created by TDK that have had a significant impact on society—ferrite cores, music cassette tapes, multilayer inductors, and thin-film magnetic heads—as the four great innovations. Not only have these four ground-breaking products from TDK had an impact on society and culture, the technologies created from them continue to be used in TDK’s current product development.

- Ferrite cores:Dramatically improved the performance of radios and televisions, supporting a culture where people can share the emotions generated by music and images.

- Music cassette tapes:TDK developed the world’s first music cassette tapes, giving rise to vast changes in the way that people enjoy music.

- Multilayer inductors:These revolutionary inductors manufactured by layering thinelectrodes have contributed to the miniaturization of consumer electronics.

- Thin-film magnetic heads:Made high-capacity HDDs possible, supporting the proliferation of PCs and the development of IT.

Ferrite Tree

Future Ferrite Tree

TDK’s trajectory of continuous growth based on technology

The Ferrite Tree expresses TDK’s growth trajectory as it has developed business with ferrite magnetic material as its founding business and links that trajectory to the technological connections with the four great innovations. Since commercializing ferrite, TDK has achieved growth of technology branches and leaves through the development of materials, processes, and derivative technologies and the expansion of the business portfolio through M&A. By strengthening current business while searching for future fields, conducting research and development, and honing our core technologies, we will grow the Ferrite Tree even larger.