Sustainability | EnvironmentInitiatives for the Circular Economy

Our Approach

In response to the need for a transition to a circular society, TDK is advancing activities from the perspective of effectively utilizing limited resources. In fiscal 2007, we achieved 100%* recycling of waste generated from our business sites without resorting to landfill or simple incineration. Since then, we have maintained this level while promoting initiatives to suppress the generation of waste itself.

We also promote a circular economy that maximizes efficiency of resource usage throughout product life cycles, thereby reducing the amount of resources used. In this way, we contribute to building a circular society by minimizing dependencies and impacts on natural capital.

*Excluding items that cannot be recycled independently due to legal regulations.

Governance

Monitoring by the Board of Directors

At TDK, the environmental officer carries out a management review at least once annually of the state of progress of general environmental matters, including climate change and natural capital, as well as plans and risks. The results of the management review and matters requiring management decisions are deliberated in the Executive Committee and, if necessary, the Board of Directors.

Management’s role

Regarding environmental risks, including climate change and natural capital, TDK has clarified the responsibilities of the environmental officer, who is appointed by the President and CEO. In addition, to strengthen the risk management framework, TDK has established committees directly under the Executive Committee. Of them, the Enterprise Risk Management (ERM) Committee has been set up with the aim of ensuring a company-wide response to factors impeding the achievement of business targets and business operations. The ERM Committee discusses important matters among environmental risks, including climate change and natural capital. The chair of the ERM Committee is a corporate officer appointed by the President and CEO.

Strategy

TDK utilizes various resources to manufacture its products, with the result that waste is generated during our business activities. The use and application of these resources involves dependencies or impacts on, for example, natural capital (freshwater, seawater, soil, and air) and ecosystem services. We will evaluate our points of contact with nature, including biodiversity, as well as our dependencies and impacts, risks, and opportunities, and then consider strategies for the effective use of resources, in line with the LEAP approach of the TNFD.

In addition, for waste, we will ensure proper disposal in compliance with relevant laws and regulations, thus endeavoring to preserve our living environments.

Evaluation method

-

Dependencies and impacts on natural capital

We will evaluate dependencies and impacts on ecosystem services for TDK and industry sectors/sub-sectors in the value chain, as well as evaluating materiality using ENCORE. We will also clarify the relationships between ecosystem services and natural capital.

We will survey the points of contact between our company and its sites within the value chain with nature, utilizing tools such as the Integrated Biodiversity Assessment Tool (IBAT), Global Forest Watch, and WWF Risk Filter (Biodiversity & Water).

Based on this data, we will diagnose sites with high dependencies and impacts on nature as well as activities relating to resource cycles. -

Evaluation of risks and opportunities

TDK will evaluate risks and opportunities based on dependencies and impacts on nature.

Risk Management

TDK promotes company-wide measures against factors (risks) that hinder the achievement of organizational goals and has established an Enterprise Risk Management (ERM) Committee, chaired by a corporate officer appointed by the President and CEO, to implement company-wide ERM activities to appropriately manage them.

Regarding the activity status of the committee, TDK has ensured that a structure for receiving advice in relation to enhancing the risk management system and increasing its effectiveness (including, but not limited to, identifying, evaluating, and reviewing material management risks at TDK and establishing effective countermeasures) is in place through regular confirmation and audit by the Audit & Supervisory Board members and the internal audit department. In addition, we will seek advice from specialists, including outside legal counsel and other experts, as needed regarding risks surrounding TDK.

The ERM Committee promotes company-wide risk management in a way we analyze and evaluate company-wide risk, identify risks which require countermeasures and decide a responsible function to be in charge of risks. As for each risk, the responsible function takes the lead in countermeasures and the progress is monitored in ERM Committee. We discuss the risk analysis evaluations and countermeasure situations at the Executive Committee and report them to the Board of Directors. Risks concerning sustainability, such as risks concerning corporate social responsibility, climate change and natural capital, securing personnel and training personnel are also allocated to risk owner departments and director is assigned for it.

For general environmental risks and opportunities, including climate change and natural capital, the safety and environment function, will monitor changes in the external and internal environment related to climate change and natural capital. We also utilize the TNFD LEAP approach to identify nature-related risks and opportunities which impact our business.

Metrics and Targets

Goals and Achievements in Fiscal 2024

| Fiscal 2024 Goal | Achievements |

|---|---|

| Improve waste intensity by 1.5% compared with the previous fiscal year | Improved by 3.5% compared with the previous fiscal year |

- *The figures have been corrected retroactively.

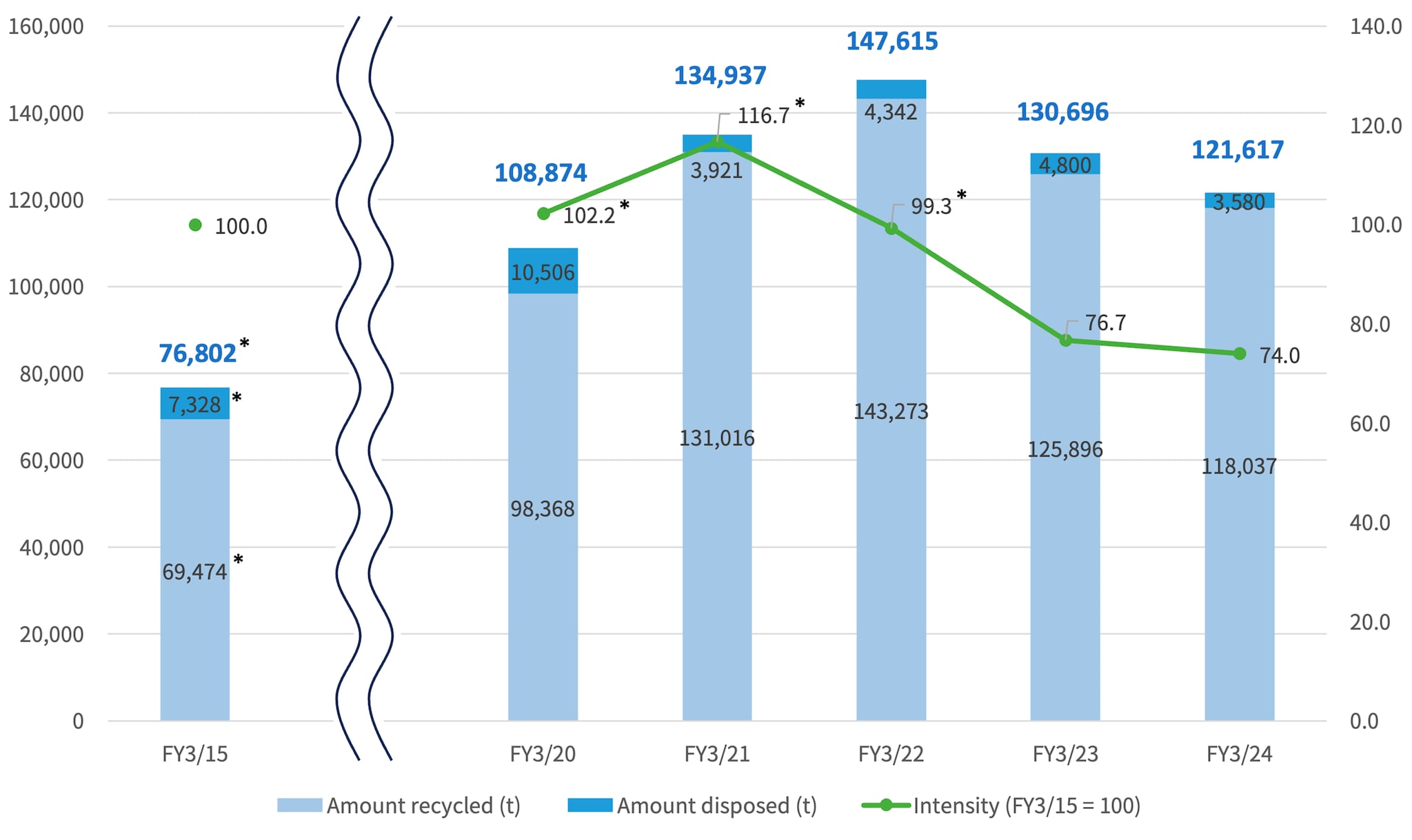

Evaluations and Future Activities

In fiscal 2024, the total amount of waste generated decreased by 6.9% year-on-year to 121,617 tons, as a result of optimizing the amount of resources inputted to match the production items and promoting waste reduction activities. Additionally, the intensity of waste improved by 3.5% compared to the previous fiscal year, achieving our target.

| Fiscal 2025 Goal |

|---|

| Improve waste intensity by 1.5% compared with the previous fiscal year |

Initiatives

Under the TDK Environmental Vision 2035, we have formulated the TDK Environment, Health and Safety Action 2025 as the environmental basic plan extending through year 2025. This plan includes targets and activity measures related to waste, and the entire group promotes initiatives based on the plan.

Furthermore, in the promotion of such initiatives, we also seek to foster an awareness of the effective use of resources among employees through awareness-raising and environmental education programs.

Waste Reduction Activities

Each manufacturing site conducts a waste assessment in accordance with its environmental management system and identifies opportunities to reduce waste generation. Depending on the opportunities identified, appropriate actions are taken at each site to reduce waste generation, for example, by reviewing and improving manufacturing processes.

■Efforts to Halve Hazardous Waste

The Malaga Factory in Spain, which belongs to TDK Electronics Components, promoted a project to reduce the hazardous waste occurring in the manufacture of film capacitors, such as metallic film, capacitor scrap, and curing resin.

By the continued implementation of such measures as improved yield through optimization of the heat-treatment process and enhancement of resin use efficiency, the factory succeeded in reducing waste, including hazardous waste, by 64%.

At the same time, the Malaga Factory is also striving to reduce the load on the global environment through such activities as revision of the operation of air-conditioning equipment and the installation of solar panels.

■Recycling of Waste from Manufacturing Process

In addition to efforts to reduce waste generation itself, the TDK Group actively promotes the recycling of waste generated in the manufacturing process of its products. Waste recycling is the process of recovering waste as a reusable resource. By sorting waste and selecting appropriate disposal methods, we sort out recyclable waste and send as much of it as possible to the recycling process for reuse.

For example, in addition to internal recycling efforts, such as collecting and reusing liquid chemicals used in the process, we have established partnerships with highly reliable external processors to collaborate on waste recycling, such as selecting processors capable of recycling scrap metal.

Product focused initiatives

■Initiative from Product Design (Power Inductors Using Recycled Materials)

In the CLT32 series of power inductors, TDK is increasing the ratios of recycled iron and recycled copper used; in total, the product contains more than 50% recycled metals. In addition, silver and nickel used to be essential in this series to realize the traditional level of performance. But efforts at the time of development and design have borne fruit, and now the inductors can be manufactured with no silver and just a little nickel. This initiative has led to the curbing of procurement and manufacturing costs.

The features of the CLT32 series of power inductors are their high output, compactness, low energy consumption, and long life. They have been certified as Super Eco Love products.*

*Among environment-conscious products, TDK certifies products that have a substantial effect in reducing the environmental load and lead others in the industry as Eco Love products. And among these Eco Love products, we certify products that have an especially substantial effect and are positioned at the top level in the industry as Super Eco Love products.

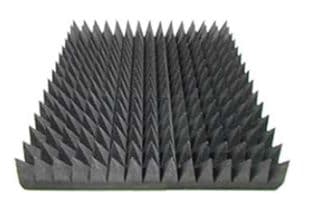

■Industry's First Biomass Plastic Electromagnetic Wave Absorber

The IS-BP series is an electromagnetic wave absorber that uses foamed polyethylene as a base material and utilizes the ohmic loss of carbon. It is installed on the walls of anechoic chambers used for evaluating antennas and wireless communication devices. Containing more than 25wt% biomass plastic, it is an environmentally friendly product that reduces CO2 emissions by 13% compared to the conventional product (IS-012A). It is certified by the Japan BioPlastics Association (JBPA).

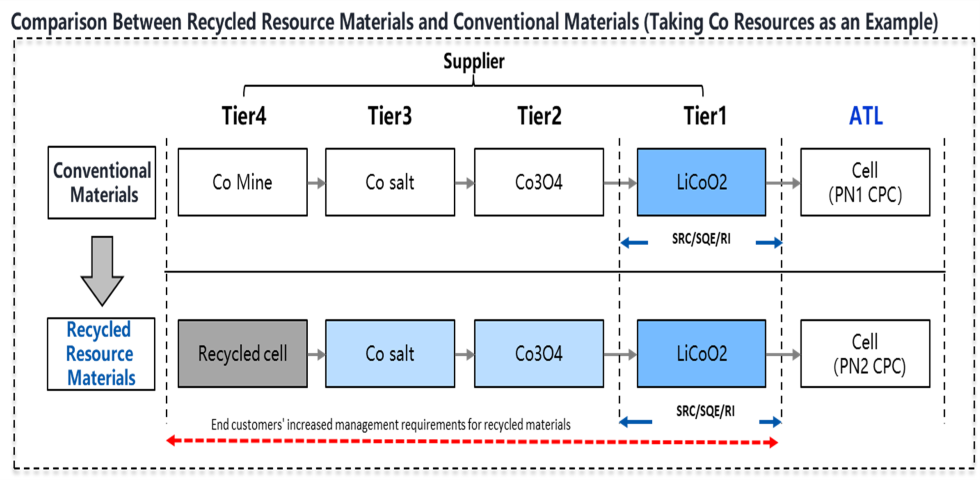

■Recycling and Reuse of Lithium-Ion Batteries (Amperex Technology Ltd.)

Lithium-ion batteries use rare metals such as cobalt and lithium. Due to the limited availability of these resources, recycling used batteries is crucial. Amperex Technology Ltd., a battery manufacturer, has started a project in 2023 to use recycled cobalt and lithium as battery raw materials in cooperation with recyclers, refiners, and cathode material manufacturers.

In fiscal 2024, more than 20% of the raw materials for batteries were recycled cobalt. This recycling effort is estimated to reduce CO2 emissions by 71,500 tons. The company also actively incorporates recycled lithium and other raw materials. Moving forward, we will continue to build a circular economy for battery resources and contribute to the development of a sustainable battery industry.

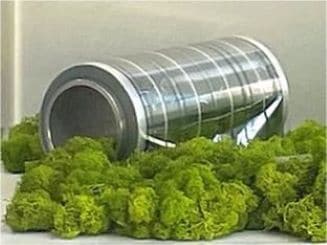

■World's First Bio-Capacitor Series (TDKElectronics Components, S.A.U., Malaga)

The ModCap®series capacitors use renewable bio-based polypropylene for the polypropylene film used as the dielectric. The Malaga plant, where this film is produced, is certified according to the International Sustainability and Carbon Certification (ISCC) standards.

This market-first bio-capacitor series contributes to reducing the carbon footprint and supports the circular economy.