The Vital Role of Thermal Management in Unlocking EV Performance

Recent years have seen the adoption of electric vehicles (EVs), characterized by their low CO₂ emissions. The transition from combustion engine and hybrid vehicles to fully electric ones, which run solely on batteries and motors, has shifted the focus of development engineers away from engine design to entirely new challenges unique to EVs. Read on to learn about thermal management systems that hold the key to unlocking EV performance and the roles played by TDK technologies.

Why thermal management impacts EV performance

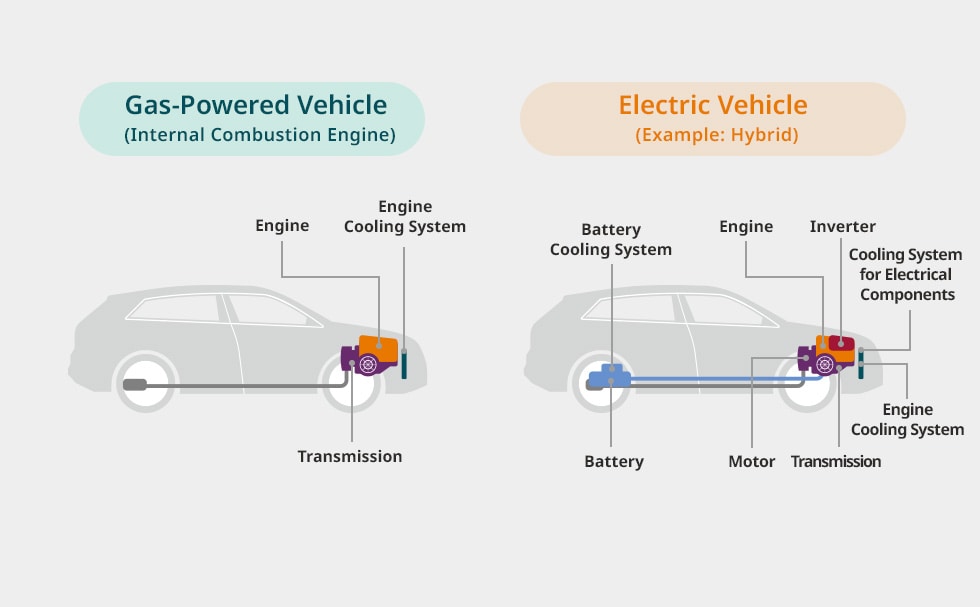

In conventional gas-powered cars, heat generated by the engine during combustion can be utilized to warm the passenger compartment, engine oil, and other components. EVs, on the other hand, have such high thermal efficiency that internal components—including the battery and motor—cannot serve as heat sources. Consequently, EVs require heaters to maintain a comfortable cabin temperature, drawing precious power away from the same battery used for driving. Also, lithium-ion batteries used in EVs must be cooled or heated, depending on the ambient temperature to maximize their performance and extend the vehicle’s driving range. If a lithium-ion battery becomes excessively hot, not only will its lifespan be shortened, it will directly translate to longer charging times, shorter range, and other performance degradations. In short, due to the dual requirements of comfort and battery power conservation, effective thermal control is far more critical in EVs than in gas-powered vehicles.

Thermal systems of combustion engine cars and EVs compared

Thermal management technology for EVs

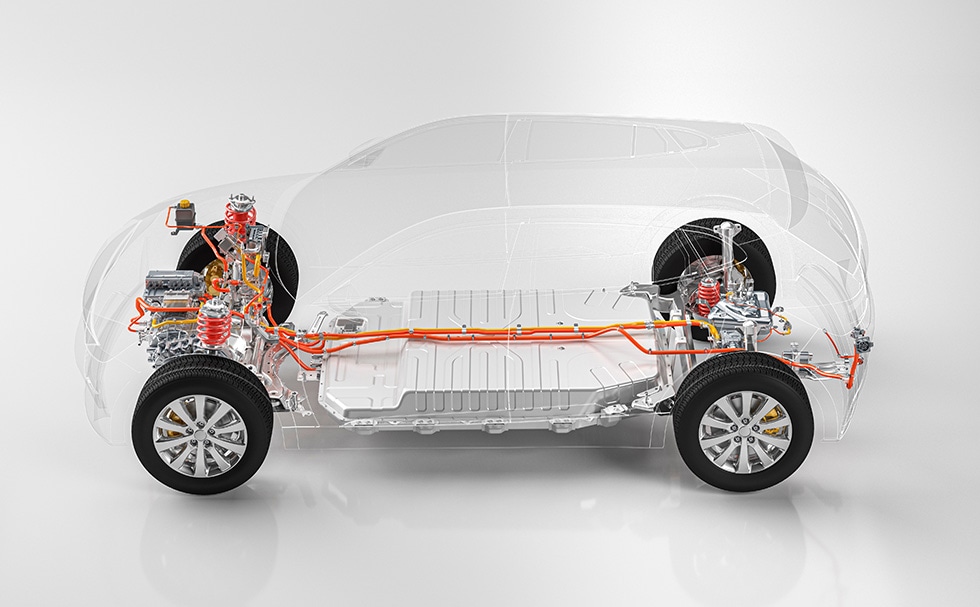

In an EV, the thermal management system is for controlling the temperatures of various vehicle components is very complex: It cools and heats the battery and motors efficiently, keeping components at their optimal operating temperatures. It also works in conjunction with the climate control system’s heaters and heat pumps to maintain a comfortable cabin temperature for the occupants. Additionally, a thermal management system responds to temperature changes in the outside environment. During the winter or in cold climates, it prevents the battery temperature from dropping too low and suffering performance degradation, ensuring stable operation even in low-temperature environments.

The system keeps components at their required temperatures by relying on either air cooling, which draws in outside air, or liquid cooling, which uses refrigerants. One example is a cooling system that evenly circulates refrigerant to each battery cell to prevent overheating. A similar system is also used to cool motors.

TDK sensors and motor controllers are well suited for thermal management

Hall sensors and embedded motor controllers are electronic components essential for controlling air cooling systems and for regulating the flow of refrigerant fluids. In air cooling systems, motor controllers are used to manipulate a device known as an active grille shutter mounted behind a vehicle’s front grille. Based on the thermal needs of the components inside the vehicle, and the driver, the motors driving the grille shutter are precisely controlled to regulate the inflow of outside air that cools the components. When air cooling is unnecessary, the shutter can be closed to reduce aerodynamic drag and extend the vehicle’s range.

Motor controllers are also used in liquid cooling systems where motors drive the valves controlling the distribution of fluids, refrigerant and water, while Hall sensors help tune the distribution. This allows the flow of refrigerants to be finely adjusted, enabling the battery, motors, and other components to operate at proper temperatures.

Product Line Manager, HVC

TDK-Micronas

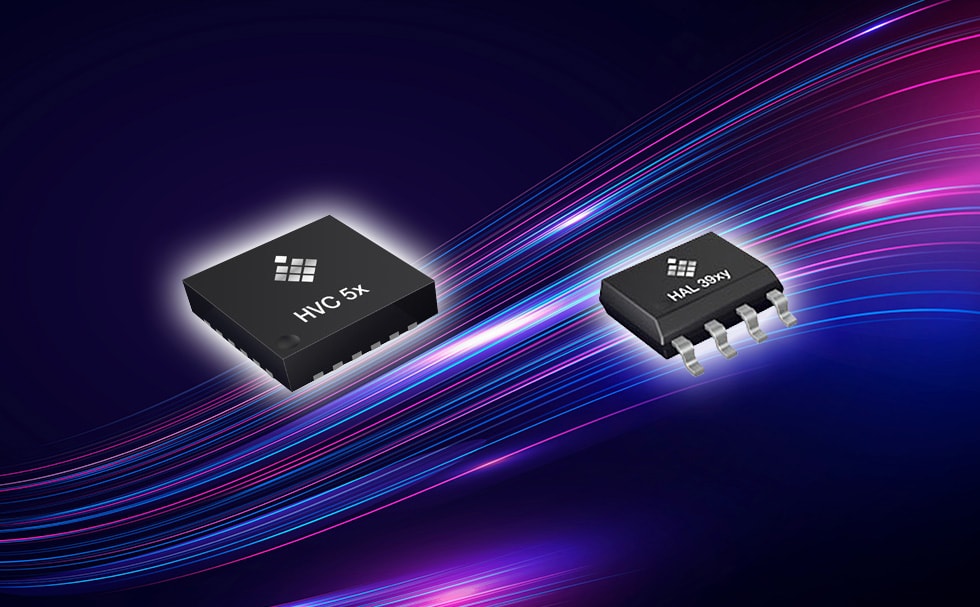

Hall sensors and embedded motor controllers, available under the Micronas brand, are broadly used in the actuators of numerous cooling systems. They function accurately under a wide range of temperature environments, precisely controlling grille shutters and valves for air cooling, contributing to the performance improvement of EVs.

Berko Kletzander, responsible for product marketing at TDK-Micronas, a TDK Group company, explains the advantages of their products. “Thermal management is crucial for both EVs and combustion engine vehicles. However, because EVs cannot use the motors as a heat source and because lithium-ion batteries need to be heated or cooled depending on the outside temperature, more complex thermal management is required, significantly increasing the number of required components.” Kletzander continued, “TDK offers an extensive product portfolio of embedded motor controllers. The HVC 4x series, which began mass production in 2016, has already sold over 100 million units, now our HVC 5x portfolio is available to offer our customers 10 devices to design to maximizing the performance of EVs thermal systems while minimizing cost.”

Thermal management is also seen as playing a pivotal role in the future evolution of EVs. New technologies like autonomous driving systems and in-vehicle AI, for example, are sure to drive the processing power of in-vehicle computers upwards and create new thermal management challenges. Just like heat can cause a PC to freeze, a malfunction in EV functionality can lead to serious safety issues. The significance of efficient thermal management will continue to grow because it enables cutting-edge technologies to improve the performance and safety of EVs.

Embedded motor controllers and sensors by TDK