Sustainability | Governance | Supply Chain ManagementSocial and Environmental Consideration at Manufacturing Sites

Our Approach

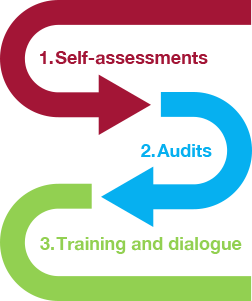

As a supplier, TDK recognizes the importance of fulfilling our social responsibilities by striving for social and environmental considerations at the Group’s manufacturing sites in order to continue our business. We strive to understand issues and make continuous improvements in a three-stage framework comprising self-assessments, audits, and training and dialogue.

Governance

The Safety and Environment Group oversees the management of risks and opportunities relating to social and environmental considerations at our manufacturing sites, and this is promoted via the appointment of a person in charge at each regional headquarters. We also report to the Board of Directors twice a year.

Education and Awareness Raising

We conduct e-learning programs on an annual basis for all TDK Group team members (employees). We also implement CSR internal auditor training for personnel in charge of manufacturing sites in Japan, China, and ASEAN, and have stationed personnel capable of conducting CSR internal audits in each region.

Strategy

We promote our CSR activities based on TDK Transformation, our long-term vision. In addition, as a member of the Responsible Business Alliance (RBA), we are rolling out assessments which use the RBA’s global standards to all our manufacturing sites, in our initiatives to address societal challenges.

We carry out activities to enhance CSR management across the Group under a PDCA cycle using the following framework.

(1) Self-assessments and risk assessments

For risk assessments, we conduct annual assessments based on RBA standards for “labor” and “ethics,” with remedial action then instituted for all identified risks. We also promote risk mitigation in human rights and ethics.

We carry out separate risk assessments for health and safety / environment.

(2) Audits

For audits, we implement third-party audits, including RBA-authorized audits, at all manufacturing sites over a medium-term three-year period to maintain a predetermined level of CSR management, and are continuously working towards addressing societal challenges.

(3) Education

We implement regular sustainability and CSR internal auditor education, with the number of personnel possessing CSR internal auditor skills increasing each year.

Risk Management

The Safety and Environment Group conducts risk assessments at all manufacturing sites for “labor,” “ethics,” “health and safety,” and “environment,” as well as conducting risk assessments of suppliers based on RBA standards in cooperation with the responsible department to promote identifications of, and improvements with regards to, challenges. We implement the PDCA cycle with continuous improvements and mitigate identified risks to the minimum to enhance our CSR management in the supply chain.

Metrics and Targets

Goals and Achievements in FY March 2025

| FY March 2025 Goal | FY March 2025 Achievements |

|---|---|

| Achieve 100% implementation of CSR self-checks at manufacturing sites (TDK Group manufacturing sites) | Achieved 100% implementation |

| Achieve 100% implementation of labor, human rights, and ethics risk assessments at manufacturing sites (TDK Group manufacturing sites) | Achieved 100% implementation |

| Achieve 100% implementation of either RBA-authorized audit (VAP, AMA, or CMA) or CSR assessment based on the RBA’s VAP standards at least once during the three-year period from 2024 to 2026 | Achieved implementation at 21% of sites in FY March 2025 |

| Conduct training for personnel involved with CSR in Japan and overseas | Conducted CSR internal auditor training in Japan, China, and the ASEAN region |

| Achieve 100% implementation of labor, human rights, and ethics internal audits at targeted manufacturing sites | Achieved 100% implementation at targeted sites |

Evaluations and Future Activities

We have begun implementing a program to have either RBA-authorized audit or CSR assessment based on the RBA’s VAP standards performed at least once during the three-year period from FY March 2025 to 2027 at all manufacturing sites. In FY March 2025, audits were performed at 21% of manufacturing sites, achieving our goal for the first year of the Medium-term Plan.

| FY March 2026 Goal |

|---|

| Achieve 100% implementation of CSR self-checks at manufacturing sites (TDK Group manufacturing sites) |

| Achieve 100% implementation of labor, human rights, and ethics risk assessments at manufacturing sites (TDK Group manufacturing sites) |

| Achieve 100% implementation of either of RBA-authorized audit, customer CSR audit, or CSR assessment based on the RBA standards at all our manufacturing sites at least once every three years |

| Conduct training for personnel involved with CSR in Japan and overseas |

| Achieve 100% implementation of labor, human rights, and ethics internal audits at targeted manufacturing sites |

Initiatives

Self-assessments

| Frequency | Target site | Content | |

|---|---|---|---|

| CSR self-checks | Every year | All TDK Group manufacturing sites | Personnel at each site respond to a questionnaire on RBA check items (human rights, health and safety, environment, and ethics). Improvement measures are taken at each site based on feedback from the survey results. |

| Labor, human rights, and ethics risk assessments | Every year | All TDK Group manufacturing sites | The check items are updated every year based on social trends. Personnel at each site respond to a questionnaire. Based on the assessment results, improvement plans are developed and implemented. |

CSR Self-Checks

At TDK, we use the Self-Assessment Questionnaire (SAQ) provided by the RBA to conduct annual self-checks regarding labor (human rights), health and safety, the environment, ethics, and management systems at all of our manufacturing sites. The purpose is to get a sense of the current status of CSR activities at manufacturing sites, to identify and address potential issues, and to promptly respond to requests from customers for CSR surveys.

After the staff in charge at each site have answered the questionnaire, the Sustainability Promotion HQ analyzes the responses and provides feedback where necessary.

In FY March 2025, of all the sites where CSR Self-Check was conducted, feedback to improve issues was provided to two sites at which issues were identified as a result of evaluations.

Labor and Corporate Ethics Risk Assessments

Every year, risks relating to labor and corporate ethics are evaluated and analyzed at all manufacturing sites, and risk mitigation is performed (environmental and health and safety evaluations are performed separately).

The items to be checked are updated each year based on social trends, etc. After the responsible personnel at each site have completed the questionnaire, the Sustainability Promotion Department assesses risks and provides the sites with feedback on the results of their assessment. If residual risks are discovered, plans for improvement are formulated and the issues are corrected at each affected site, so as to minimize risk. By performing the PDCA cycle at each site, we aim to achieve ongoing improvement.

In FY March 2025, we conducted labor and corporate ethics risk assessment based on Version 8.0 of the RBA standards. Based on the assessment results, latent risks were identified at 19 sites; the implementation of remedial measures had been completed at all these sites by the end of the fiscal year.

Audits

The main types of CSR audit promoted by TDK are RBA-authorized audits and CSR assessments based on the RBA’s auditing standards. By conducting audits based on the RBA standards, we have constructed a mechanism to ensure that the levels of labor affairs, health and safety, environment, ethics, and management systems are maintained at a global standard.

In addition, we have set ourselves the goal of having either RBA-authorized audit or CSR assessment based on the RBA’s auditing standards performed at least once during the three-year period from FY March 2025 to 2027 at all manufacturing sites. In FY March 2025, audits were performed at 21% of manufacturing sites, achieving our goal for that year.

| Frequency | Target site | Content | |

|---|---|---|---|

| RBA-authorized audit | Starting FY March 2025, launched initiative to conduct either an RBA-authorized audit or a CSR assessment based on the RBA audit standards at all manufacturing sites at least once every three years | Priority target sites based on Medium-Term Plan | RBA-authorized audit (VAP, AMA, or CMA) |

| CSR assessment based on the RBA audit standards | Site where no RBA-based audit has gone in |

|

|

| Customer CSR audit | As necessary | Sites requested by customers | Performed based on customer's audit standards |

| Internal audit | Every year | Site where high-level management is requested |

|

Trainings and Dialogues

With a systematic understanding of RBA and customer requirements related to CSR, we provide timely training for quick responses.

In FY March 2025, we held CSR internal auditor training provided by an RBA-authorized auditing firm on a global basis. In the ASEAN region, we arranged for on-site auditing to be performed by a third-party organization, and we implemented training to upgrade the skills of CSR internal auditors.

On-site Auditing of Contract Worker Agencies

We have been implementing on-site CSR auditing at our manufacturing sites, targeting suppliers (including staffing services firms and other service providers). If issues are discovered, we implement monitoring of every stage from the formulation of improvement plans through to the completion of corrective action.

Consideration for Human Rights in Relation to Employees at TDK Manufacturing Sites

We conduct CSR self-checking based on RBA standards, and labor and corporate ethics risk assessment, for all manufacturing sites in the TDK Group on an annual basis. This is overseen by the Sustainability Promotion Department. In addition, we have set ourselves the goal of having either RBA-authorized audit or CSR assessment based on the RBA’s auditing standards performed at least once every three years at all manufacturing sites. When issues are discovered during the implementation of these measures, we require the affected site to draw up a plan for improvement and implement corrective action.

In FY March 2025, CSR self-checking using RBA self-assessment, and labor and corporate ethics risk assessment, were performed at all 75 of our manufacturing sites. Risk assessment in relation to human rights covered forced labor, harassment, and management of service providers such as contract worker agencies, cafeteria management firms and security firms. The labor and corporate ethics risk assessment identified latent risks at 19 sites; the implementation of remedial measures had been completed at all these sites by the end of the fiscal year. Going forward, we will continue to implement initiatives, using the measures outlined above, to reduce the risk of human rights infringements.