Sustainability | Sustainability Management | Efforts to Achieve the SDGsTDK Group's Approach to the SDGs

- The TDK Group's Approach to the SDGs

- Building a Setup to Address the SDGs through Business

- Enhancing the Objectivity and Accurateness of Disclosed Information

TDK Group's Approach to the SDGs

To make the global environment and people’s lives sustainable, the United Nations General Assembly approved the 2030 Agenda for Sustainable Development in September 2015. This agenda advocates Sustainable Development Goals (SDGs), consisting of 17 goals and 169 targets, to be achieved by all countries by 2030.

Under our long-term vision, “TDK Transformation—Accelerating transformation for a sustainable future,” TDK aims to accelerate the evolution of technology and the transformation of society through electronic devices by combining its unique materials, processes, and software, thereby contributing to the realization of a sustainable future. Further, by continuing to transform itself, TDK aims to grow alongside its global customers as their No. 1 partner.

For TDK, the SDGs are the starting point of value creation. We believe that the measurement of how much value we have supplied to society and how much we have contributed to the solution of social issues is a barometer of our business achievements.

Building a Setup to Address the SDGs through Business

The TDK Group is continuing efforts, as explained below, to identify and implement available countermeasures and how TDK’s products and technological strengths can be exploited to tackle the global issues specified in the SDGs.

In the term when measures are started, in addition to general in-house education, in accordance with company policy, we conducted an in-house dialogue with business groups in Japan and overseas regarding the approach to sustainability that the TDK Group should be aiming for and the SDGs. After that, of the issues cited in the SDGs, we summarized the discussions that took place in each business group about what issues and targets could be addressed by their own technologies and solutions in the medium and long term and whether there were any technologies and solutions that could be newly created stemming from social issues. The results are organized and the business groups and the Sustainability Promotion HQ conducted discussions on priority areas and medium- to long-term strategies.

Subsequently, we have been working to continuously improve measures as the creation of mechanisms. In the investigation results of each business group that can be achieved in the short term have been incorporated into business plans since FY March 2021. After organizing the results, we report a summary and review of the results for all business groups to the Board of Directors and also engage in dialogue with each business group for the purpose of reviewing the implementation status in the previous fiscal year and improving activities for the following fiscal year.

Going forward, we will communicate inside and outside the company to share the results of the above activities and promote activities.

Process:

- Implementation of employee educational dialogue to deepen understanding of the SDGs (since June 2018)

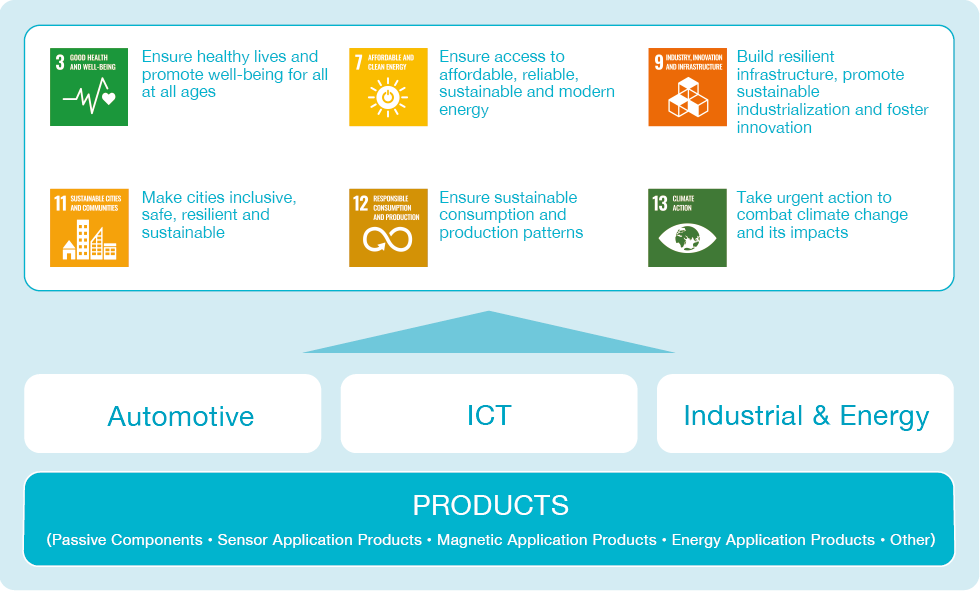

- Discussion by questionnaire or interview of what products or technologies possessed by each business group could contribute to the achievement of goals 3, 7, 9, 11, 12, and 13 of the SDGs (May–November 2019)

- Inclusion of discussed ideas into the FY March 2021 business plans of each business group (October 2019 – March 2020)

- Promotion of dialogue with business groups and other related parties and consideration of TDK’s priority areas and strategy based on social issues (since April 2020)

- Implementation of integrated progress management combining the EX and DX specified in the TDK Group’s materiality with the business areas that TDK focuses on for social value creation and corporate growth (since April 2021–March 2024)

- With the aim of making visible the social impacts of TDK’s business activities that contribute to solutions to social issues based on TDK Transformation, our long-term vision, we revised the details of questionnaire. Progress management is continuously implemented (since April 2024).

Contribution to achieving the SDGs

Enhancing the Objectivity and Accurateness of Disclosed Information

Regarding environmental performance data, TDK has been receiving third-party verification and third-party reviews by SGS Japan Inc.