Sustainability | SocietyHealth and Safety

Our Approach

The TDK Group Occupational Health / Safety and Environmental Charter

To unify policies relating to health / safety and the environment throughout the entire TDK Group, TDK formulated the TDK Group Occupational Health / Safety and Environmental Charter consisting of two aspects—basic principles and basic policies on health/safety and the environment.

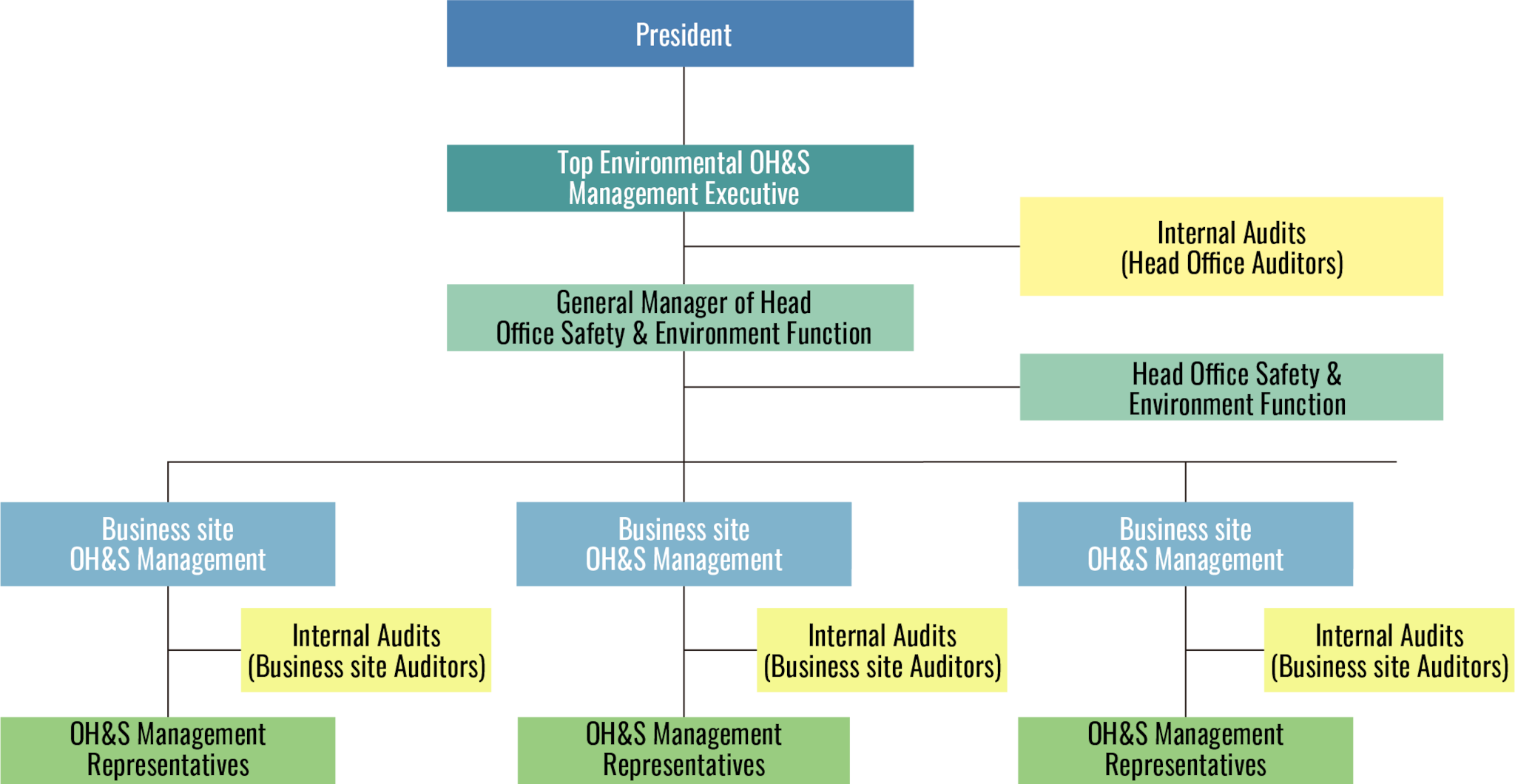

Governance

TDK has set up a promotional structure based on the Occupational Health and Safety Management System headed by the President and CEO. In addition, important matters related to health and safety are reported to the Board of Directors, and are deliberated when necessary.

Strategy

The TDK Group has established and implemented the TDK Occupational Health and Safety Management System (TDK OHSMS) in accordance with the requirements of the international standard ISO 45001:2018 for occupational health and safety management. Within the operation of the TDK OHSMS, we conduct risk assessments and carry out risk elimination and reduction activities such as "exposure to chemical, biological, and physical agents," "tasks that place physical strain on workers," and "safety confirmation and evaluation of production machinery." Additionally, we strive to manage public health by providing clean water and sanitation facilities, ensuring a safe, healthy, and fair working environment for all team members (employees).

Risk Management

Promotion of Occupational Health and Safety Management System

The activities of the TDK OHSMS are carried out in accordance with national and regional standards and regulations. As of the end of March 2025, 80% of all our factories within the group have obtained ISO 45001:2018 certification. Additionally, in the Americas, we have obtained OSHA* certification and are advancing certification activities appropriate for each country and region.

Furthermore, we have established EHS coordinators (Environmental, Health, and Safety coordinators) in Japan, China, ASEAN, Europe, and the Americas to promote safety, health, and environmental activities by conducting factory safety audits and sharing best practices in safety and environmental meetings to improve the level of safety and health activities.

*OSHA: Occupational Safety and Health Administration

Related Link

Metrics and Targets

Goals and Achievements in FY March 2025

| FY March 2025 Goal | Achievement |

|---|---|

| Achieve zero significant labor accidents | Zero significant labor accidents |

Related Link

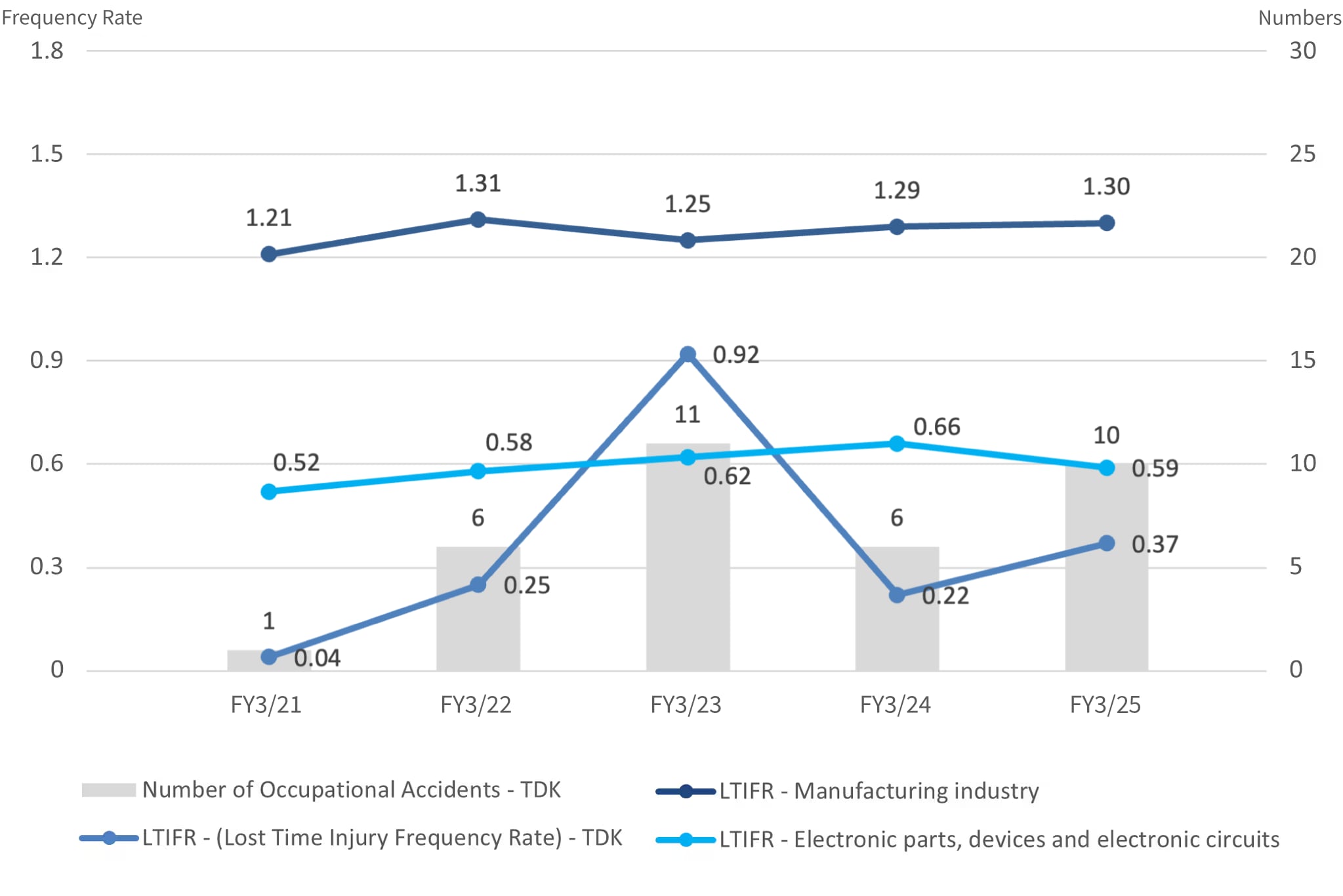

Evaluations and Future Activities

In FY March 2025, there were no fatal or significant labor accidents* within the TDK Group. Going forward, we will continue our efforts to prevent labor accidents through activities aimed at eliminating and reducing risks, as promoted under the TDK OHSMS. In the event that a labor accident occurs, we carry out investigations into the root causes and implement fundamental countermeasures, review procedures, and ensure proper communication to maintain safety and prevent recurrence.

*Significant labor accident: an accident with remaining disability, required long-term nursing, or fatality.

| FY March 2026 Goal |

|---|

| Achieve zero significant labor accidents |

Initiatives

Conducting Risk Assessments

When constructing new manufacturing sites or introducing new equipment, we also conduct risk assessments to ensure comprehensive safety. In addition, to address risks identified at individual sites, we put risks in priority order, formulate action plans and targets, and take action to realize improvement.

Conducting Audits

Sites that have obtained an ISO 45001 certification are audited regularly by outside auditors from a certification authority, while an internal audit in principle is conducted once a year for those sites that yet to obtain such a certification.

Responses to Emergency Situations

In preparation for any emergency situation that may arise, we have established response procedures and a communication and reporting system for when an emergency situation occurs. We also conduct regular evacuation drills and so forth on the supposition that an emergency situation has arisen, and work thoroughly on the response procedures for such an event.

Responses to Labor Accidents

The TDK Group works to prevent labor accidents from occurring. We have in place a framework wherein, should a labor accident occur, the health and safety manager at the site where it occurred will promptly inform either the safety and environment function at the head office or the regional headquarters.

At those sites where a labor accident has occurred, we carry out investigations into the accident's root causes and implement fundamental countermeasures. At the same time, we also share information regarding these matters and work to prevent recurrence.

Education and Awareness Raising about Occupational Safety

We provide education and work to raise awareness about workplace safety such as through experience-type safety education with the goal of fostering safety awareness among our team members. Additionally, at all TDK Group manufacturing sites, we post health and safety information in our facilities in either the mother tongues of our team members or in languages they can understand, and we promote self-awareness and regularly provide competence education regarding health and safety.

Global Deployment of Experience-Type Safety Education

TDK has begun the global deployment of the experience-type safety education based on the concept of “look, listen, and feel” implemented by the TDK Safety Training Center set up at the Nikaho Factory South Site in the Akita region of Japan in 2017.

We have been undertaking initiatives to raise the safety awareness of our team members. These include having established in 2020 an EHS Training Center at TDK (Zhuhai FTZ) Co., Ltd., one of our manufacturing sites in China, and having established in April 2022 the Safety Training Center at our Mikumagawa Factory.

In addition, in response to cases of factory fires recently both in Japan and overseas, the TDK Group carries out fire-prevention inspections globally and is taking steps to reduce the risk of fire.

The total number of team members in Japan who have trained at the Safety Training Center now stands at 16,739 (2,909 in FY March 2025)

Technical Training Center Established to Improve Skills in Entire Factory (Nashik Factory, TDK India Private Limited)

The Nashik Factory in India has established the Technical Training Center to provide all team members with opportunities to improve their knowledge and skills. At this center, efforts are made to deepen new team members’ understanding of emergency health/safety response, such as fire prevention and use of automated external defibrillators (AEDs), as well as their knowledge of actual products.

The center is also used for skill improvement by all team members. For example, it is used in multifunctional training for established team members, providing displays of actual manufacturing equipment and maintenance tools that can be touched.

Furthermore, the center is resourceful in its educational programs, adopting recreational elements so that trainees do not become bored.

Health and Safety Initiatives in Our Supply Chain

The TDK Group has established a TDK Group Business Partner Code of Conduct grounded in the Group's TDK Purchasing Policies. The Code of Conduct specifies the Group's expectations for compliance in how suppliers conduct their operations, under several categories: labor, health and safety, environment, ethics, management systems, and information security. Furthermore, we expect our suppliers to recognize the risks associated with CSR and to take human rights and safety into consideration in their activities in the supply chain, as well as to reduce the environmental load of their operations.

Related Link