Venture Spirit

Relentlessly Taking on Challenges Drove TDK’s 90 Years of Innovation

The 90 years of TDK’s expansion have been powered by what the company calls Venture Spirit—a mindset that has carried forward since the company’s founding. TDK’s founder, Kenzo Saito, formed TDK (originally named Tokyo Denki Kagaku Kogyo) in December 1935. A university-origin startup, its mission was to industrialize ferrite: a magnetic material invented by Dr. Yogoro Kato and Dr. Takeshi Takei at the Tokyo Institute of Technology (now part of the Institute of Science Tokyo). For nine decades since that beginning, TDK’s Venture Spirit—creating innovation by taking on challenges—has been the driving force behind its businesses and growth. This article looks back at the Venture Spirit that guided TDK through its 90 years of transformation.

▶Related Story:

Transformation From Ferrite to the Future: TDK’s 90 Years of Evolutions and Innovations

One of Japan’s earliest university-origin startups

TDK’s Venture Spirit took root in 1930 with founder Saito’s encounter with ferrite, an oxide-based magnetic material invented by Dr. Kato and Dr. Takei. Saito had attempted numerous businesses to help improve life in his native Akita—an impoverished agricultural region—but almost all had ended in failure. He even referred to himself, retrospectively, as a man of “2 wins and 98 losses.”* Yet, undaunted by countless hardships, Saito continued taking on challenges. That persistence eventually bore fruit.

After learning about ferrite, Saito secured financial support from Kanebuchi Spinning’s Shingo Tsuda personally, who was compelled by Saito’s vision. On December 7, 1935, he founded Tokyo Denki Kagaku Kogyo. It was an audacious start, built on a dream to industrialize a material whose applications were still unknown. TDK co-developed ferrite cores with Tokyo Institute of Technology and successfully commercialized them in 1937, ahead of the rest of the world. Adopted in wireless equipment and radios, the cores shipped five million units before the end of the war, earning the company a solid base of customer confidence.

Even today, ferrite cores remain a key product line for TDK. And this material—now backed by 90 years of history—continues to seed countless new products. Without the deep insight into materials technologies, TDK could not have achieved the many technological innovations that followed.

*The “2 wins” refer to Saito’s founding of TDK and his subsequent role as a House of Representatives lawmaker, where he was instrumental in creating the Science and Technology Agency.

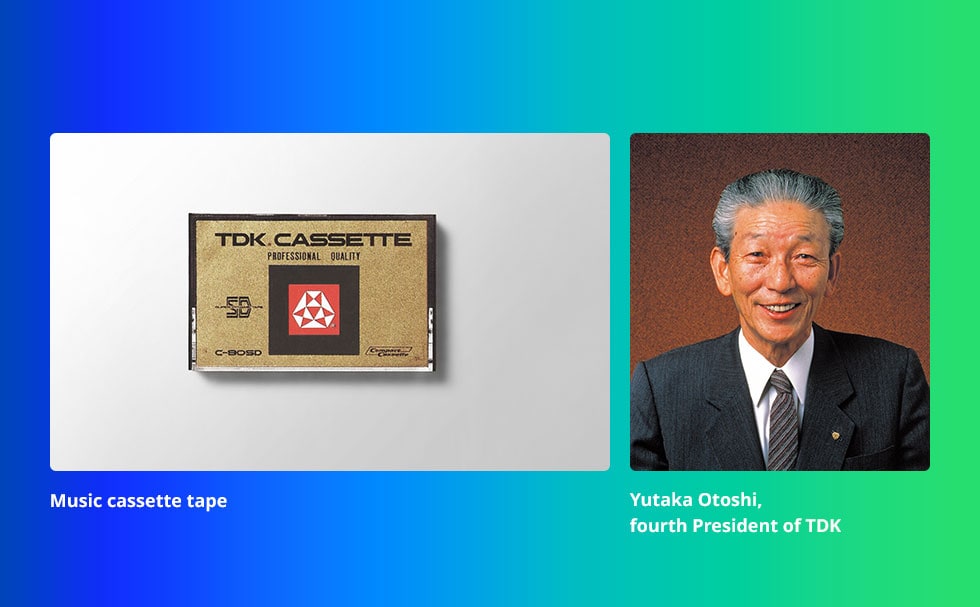

Transforming the world’s music experience: The challenge of the music cassette tape

Following ferrite cores, TDK made another sweeping impact on the world with its music cassette tapes. One of the key figures behind this breakthrough was Yutaka Otoshi, TDK’s fourth president. Eyeing the rapid growth of the music industry, he became determined to transform the compact, affordable cassette tape into a true music medium, replacing reel-to-reel tapes.

At the time, cassettes lacked full-range audio fidelity. Otoshi set a lofty goal: to record “Felix Mendelssohn: Violin Concerto in E minor Op. 64” so vividly that it would sound like a live performance. Convinced that teamwork and radical reform were necessary, he pursued a then-uncommon approach—collaborating with external partners to drive rapid technological innovation.

In 1968, TDK developed the first music cassette tape, the SD (Super Dynamic), achieving a level of reproduction quality that approached live listening. TDK then adopted an unprecedented marketing strategy: launching and promoting the product in the United States first, the heart of the global music industry. The response was enormous. People around the world soon began carrying their favorite music on cassettes, transforming music culture worldwide. Otoshi later reflected, “I don’t think there’s any other place like TDK where you can work without being bound by conventions.”

Led by music cassette tapes, the era of recording media saw TDK’s global business expansion accelerate significantly. It was during this period that the company honed its capacity to engage closely with customers and customize its products to match local market needs. The Venture Spirit born from this challenge elevated the cassette tape to a cultural icon—and the spirit continues to thrive.

Defying convention by making a coil without winding: The multilayer inductor

During the 1970s and 1980s, radio/cassette players, video cameras, and wireless equipment evolved into portable devices. Their miniaturization was supported by the shift to surface-mounted (SMD)* passive components. But one key component lagged behind: the inductor (coil). Because inductors were traditionally built by winding wires around a magnetic core, they were considered impossible to flatten or miniaturize without degrading performance. A “coil without winding” was beyond anyone’s imagination.

Magnetics Business Group

TDK Corporation

TDK decided to defy this convention. Employing a totally novel concept, the company devised a groundbreaking multilayer process that built coils by vertically stacking half-patterns. Theoretical underpinnings aside, the road to mass production was grueling. The Magnetics Business Group’s General Manager, Hidekazu Sato, recalls, “Raw materials, paste, printing, cutting, sintering, terminal formation, measurement... almost every part of the process was an unprecedented challenge.” But by embracing the technical issues encountered at every step and assiduously resolving them one by one, TDK became the first company in the world to mass-produce multilayer inductors in 1980.

This innovation played a substantial role in the downsizing of television tuners, portable music players, mobile phones, and laptop PCs, beginning in the 1980s and continuing to this day. TDK now offers a broad lineup of multilayer passive components, including multilayer inductors, multilayer ceramic capacitors, EMC components, and varistors. Without these miniaturization technologies, smartphones, wearable devices, and other compact electronics would not have been feasible.

*SMD: Short for Surface Mount Device. Refers to chip components without leads that are compatible with SMT (Surface Mount Technology), where components are mounted directly on the surface of printed circuit boards.

Enabling the personal computing revolution: The thin-film magnetic head

Asama Techno Factory

Magnetic Sensors Business Group

TDK Corporation

There was a time when computers were massive calculation machines used only by specialists. By the 1990s, as hard disk drive (HDD) capacities increased, computers increasingly became smaller and more powerful, leading to the widespread proliferation of personal computers. A key enabler of this shift was TDK’s thin-film magnetic head, developed in 1987.

Magnetic heads are primary components in HDDs, essential to writing and reading data—yet thin-film technology was uncharted territory for TDK at the time. The challenge began in 1982. Thin-film technology required semiconductor-like processes run in cleanrooms to form thin films on wafers, as well as creating three-dimensional structures through microfabrication—a highly advanced and exceptionally difficult series of tasks. The tales of struggle from those days are still retold today. Makoto Yoshida, Factory Manager of Asama Techno Factory, remembers, “We had little experience with film deposition or micromachining. Our know-how was all gained through trial and error. When equipment was lacking, we even used surface grinders to simulate spinning HDDs.”

In 1986, TDK constructed the Chikumagawa No. 2 Technical Center (now Asama Techno Factory) as a production hub. The thin-film magnetic head completed in 1987 became a core business, ushering in the shift from mainframes to personal computers. The company continued to push boundaries, introducing new technologies that repeatedly broke through presumed limits of recording density.

Today, TDK’s magnetic heads are extensively employed not only in desktop and laptop PCs but also in servers and data centers. Without them, storing photos and videos in the cloud and accessing streamed content from anywhere would be nearly impossible. TDK’s magnetic heads will continue to unlock the future of data recording technology.

A venture’s ambition sparks a revolution in lithium-ion batteries

In 1999, a small number of TDK Group employees left TDK with a shared vision: Solve the global energy problem and create a better future. Driven by this sincere ambition, they founded Amperex Technology (ATL) to research, develop, and market lithium-ion batteries. What began as a small step quickly gained momentum, and ATL enjoyed exponential growth.

In its expansion, however, the founders recognized that achieving long-term impact in markets like mobile ICT and electric vehicles would require a larger business foundation and deeper connections to core technologies. ATL approached TDK regarding a potential acquisition, believing there were significant synergies. During discussions, one of the cofounders proclaimed, “My dream is to make the skies of China clean.” His mission resonated deeply with TDK, including then-M&A lead Fumio Sashida, now CEO of the Energy Solutions Business Company.

Buoyed by a shared sense of mission and hope, ATL became part of the TDK Group in 2005. Following integration, ATL flourished, capturing the world’s largest share of lithium-ion batteries for smartphones and fundamentally reshaping communications and everyday life around the world.

The playing field of TDK’s lithium-ion batteries continue to expand, including energy storage systems, electric motorcycles, power tools, and other medium-sized battery markets. Its founding ambition—underpinned by its technologies and guiding principles—has steadily taken shape towards a cleaner future.

Pioneering an unknown frontier from scratch: TMR sensors

In 2009, the Asama Techno Factory (ATF)—TDK’s global production hub for HDD magnetic heads—set out on a bold mission to repurpose its thin-film processes and equipment for a new core business. The idea was to apply TMR (Tunnel Magnetoresistance) technology to magnetic sensors. At the time, TMR had no commercial examples outside HDD heads. Starting from scratch with no precedent or dedicated equipment, a small in-house venture team of just three members stepped into uncharted territory.

One of the then-leaders, Masanori Sakai, Senior Principal Engineer of the Magnetic Sensors Business Group, reflects, “HDDs were dominant at the time, but forecasts predicted they would eventually be replaced by SSDs. So we asked ourselves if there was a way to leverage ATF’s technologies and equipment—while we still had time—to build what could potentially become a new pillar of our business. And if we were going to try, we said we might as well go for the most technologically challenging—and that was TMR sensors.”

The TMR sensor that emerged from this effort delivered both stable performance across a wide temperature range and low power consumption, a groundbreaking combination. Brought into mass production in 2014, they have since been adopted across a broad spectrum of applications—from automotive to robotics, smartphones, and more. In vehicles, TMR technology is used in electric current and angle sensors, while in smartphones, it powers fast autofocus and other high-precision functionality.

Today, TMR sensors constitute a leading business of the Sensor Systems Business Company, established in 2017. The sensors business has grown to account for as much as 8% of TDK Group’s total revenue. The refusal to settle for the status quo, the courageous repurposing of technology for the future, and TDK’s Venture Spirit—all culminated in a truly innovative outcome.

TDK Ventures: Catalyzing TDK Transformation to Shape Industries and Societies

Nicolas Sauvage

In April 2019, TDK took a decisive step toward its next frontier with the creation of TDK Ventures, a corporate venture capital firm designed to explore where TDK might go next. By investing in entrepreneurs addressing the world’s most pressing societal challenges, TDK secures early insight into new & emerging markets, applications, and technologies, opening pathways for both organic and inorganic growth. The firm’s mission is to Catalyze Iconic Companies, whether they are built by external founders or by TDK intrapreneurs who aspire to create new businesses.

The idea came from an unexpected place. Nicolas Sauvage, then with InvenSense shortly after its acquisition, recognized an opportunity to extend TDK’s venture spirit. What began as a bold proposal has since grown into a platform with 50 portfolio companies and $500M AUM across 4 funds.

He recalls: “When I proposed TDK Ventures, TDK empowered me to build something entirely new, redefining what CVC can be. My career is shaped by building value with entrepreneurs who imagine a better future and work tirelessly to make it real. TDK Ventures became the engine to bring that spirit into TDK, supporting exceptional entrepreneurs and intrapreneurs ready to pursue breakthroughs.”

Today, TDK Ventures serves as a bridge and catalyst. Through this work, the venture spirit that has carried TDK for 90 years continues to evolve, nurturing new ideas, empowering builders, and opening futures that neither startups nor large enterprises could achieve alone.

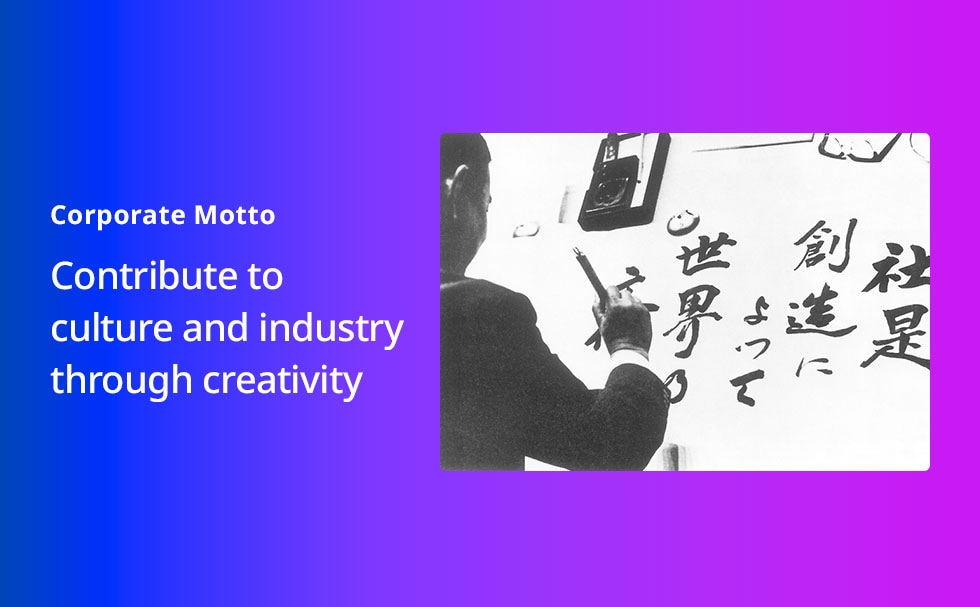

Founder Kenzo Saito’s ardor is reflected in TDK’s corporate motto, “Contribute to culture and industry through creativity.” This belief has guided TDK to deliver innovative technologies and products for nearly a century. The driving force behind this achievement is the resolve to take on challenges and overcome difficulties—the Venture Spirit. TDK will continue to take on new challenges in this pioneering mindset.