Sustainability | Society Quality Assurance Activities

- Our Approach

- Structure

- FY March 2022 Goals and Achievements / Evaluations and Future Activities

- Top Priority Measures in the "Advance to Zero Defects"

- Prevention and Control of Exposure to Hazardous Substances in Products

Our Approach

TDK pursues the corporate mission of contributing to society through the manufacture and supply of outstanding electronic components.

“Quality” is the key management axis in this quest, positioned as the top priority in activities aimed at realizing top-caliber products built to consistently live up to customers’ expectations.

Basic Philosophy

"Advance to Zero Defects"

TDK advocates the “Advance to Zero Defects” as its basic philosophy. This is manifested as to efforts to eliminate defects not only at the shipment stage, but also throughout the product life cycle spanning distribution, assembly by set manufacturers, application by end users and disposal.

Quality Policy

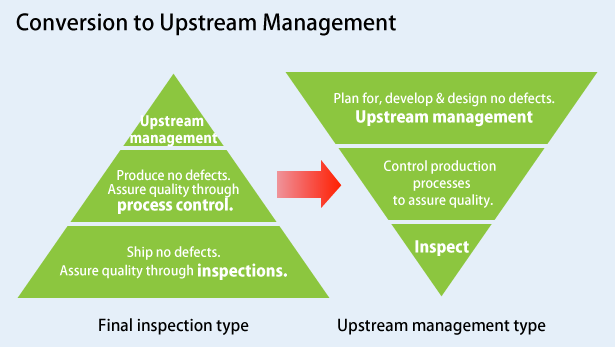

"Quality cannot be assured by final inspection!"

TDK firmly believes that “Quality cannot be assured by final inspection.”

This policy stems from the idea that simply removing defective items at final stage inspection cannot ensure sufficient product quality. Rather, the goal is to firmly instill the attitude of “building in” quality at each process to assure the excellence of 100% “good products.”

Therefore, TDK improves quality from the upstream level at the product design, process design, equipment development and all other stages. The goal is to eradicate defects and realize high-quality products that constantly earn customer satisfaction and trust.

Quality Targets

"Achieve Zero Defects" "Make TDK the leading quality-oriented company in the industry"

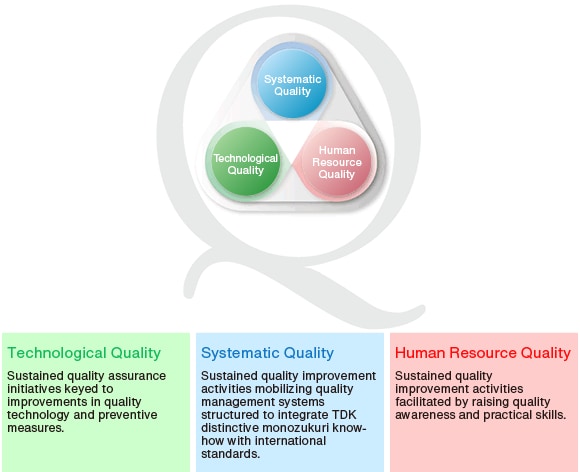

To ensure full satisfaction for customers using its products, TDK works to faithfully supply top-quality goods on a continuing basis. Quality assurance activities are advanced on the cornerstone of the three pivotal themes of “Human Resource Quality,” “Technological Quality” and “Systematic Quality.” This stance is marshaled to firmly address the targets of achieving zero defects and making TDK the leading quality-oriented company in the industry.

Structure

General Manager of headquarters quality assurance function supervises QA activities in the Group as a whole, endeavors to share and develop principles and policies, and promotes activities by the entire Group toward their realization. In addition, each business division has a QA function, the head of which supervises and executes QA activities in the division.

FY March 2022 Goals and Achievements / Evaluations and Future Activities

| FY March 2022 Goal | Achievements |

|---|---|

| Promote globalization of quality education | Provided quality education at overseas sites |

Evaluations and Future Activities

By leveraging TDK’s digital learning platform (Weconnect), we will deliver education in a timely manner with multiple languages.

| FY March 2023 Goal |

|---|

| Expand quality education globally by utilizing digital transformation (DX) |

Top Priority Measures in the "Advance to Zero Defects"

At TDK, our basic philosophy “Advance to Zero Defects” is being advanced through the following focal strategies.

(1) Strengthened design development processes

In its quest for zero defects, TDK thinks it is necessary to build product-manufacturing systems capable of turning out 100% good products in design activities. More specifically, steps are taken to define risks prone to occur in each process at an early stage, thereby creating and applying an upstream management type quality assurance system to eliminate such problems at the design phase.

(2) Strengthened product manufacturing processes

To achieve “Zero Defect Quality,” product design must be accompanied by worksite competence to establish reproducible manufacturing processes that eliminate variations. The main aspects that result in quality variations are “Equipment” and “Operations.” Variations caused by equipment were reduced by the introduction of the “Equipment Variation Assessment Method.” Variations caused by operations were addressed by the “Co-creation Challenge Activities” implemented as a small group activity. Along with this, steady endeavors to raise quality awareness and furnish quality education through small group activities are mustered to forge and uphold a “Quality First” corporate organization and culture.

TDK continues to enhance its engineering and Monozukuri power with further strengthening of its design development and product manufacturing processes. This is all part of the company’s relentless push to supply customers with higher quality products in more timely fashion.

(3) Strict compliance for quality assurance

We strive to fulfill our social responsibilities with high ethical standards in conducting corporate activities in compliance with laws and social norms. Toward this end, we continue working to improve product quality through the pursuit of zero defects, try to foster an awareness of what it means to place top priority on quality, and perform checks through compliance audits for quality.

(4) Responses to product security

In recent years, there have been incidents of new types of problem relating to IoT products that connect to networks including not just harm caused by cyber-attacks that exploit vulnerabilities via networks such as leaks of handled data or data tampering but also the use of hacked devices by attackers to cause harm.

In light of the circumstances, TDK implements countermeasures in our IoT products according to the product functions, features, sales format, and other conditions. For example, it is necessary to take into consideration security in various stages such as using secure development methods and function safety structures from the component purchasing and production processes to the design stage, and after products are sold, maintenance methods such as firmware updates throughout operation and maintenance of applications that are installed on user devices.

Security measures for IoT products will be an essential technology for the coming era of digital transformation, and TDK has positioned IoT product security as an issue of product quality. In cooperation with relevant Functions, TDK has established implementation structures and rules to respond to cyber security issues including incidents involving TDK IoT products and will strive to provide products that gain the trust and confidence of customers.

(5) TDK’s continuous implementation of quality education to employees

Learning lessons from a past humidifier accident, TDK regularly implements education for all employees of the TDK Group to raise their awareness of the top priority that must be given to product safety and quality. The content of videos used as materials in this educational program is regularly updated to take account of incidents occurring and requirements in the market.

In addition, to advance the program globally, TDK is promoting expansion in terms of its availability in multiple languages and various methods of transmission.

Prevention and Control of Exposure to Hazardous Substances in Products

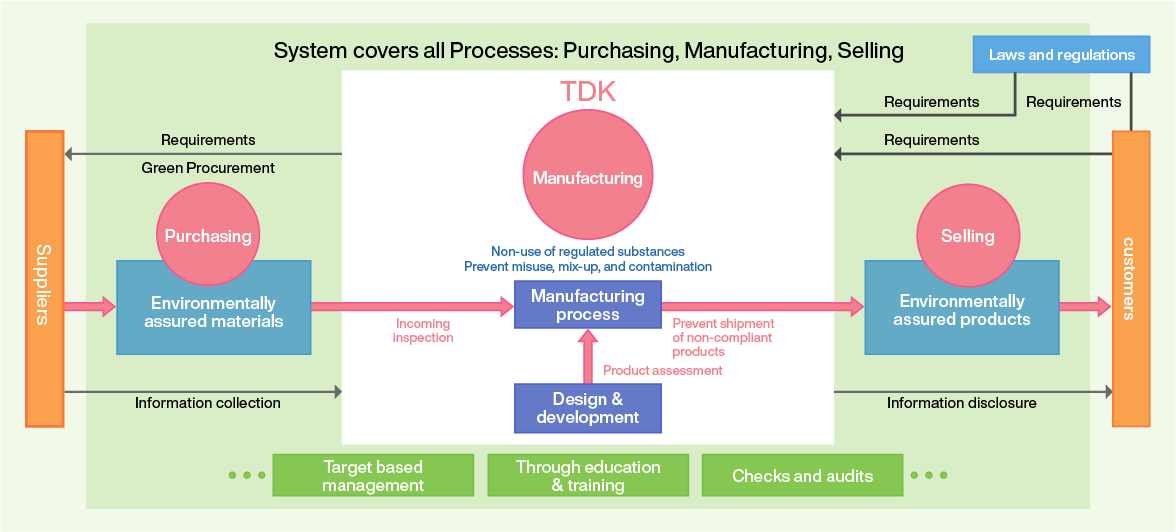

To prevent and control exposure to hazardous substances that originate with our products and that could threaten people's health and the environment, in 2004 TDK introduced an Environmental Product Quality Management system that is operated under our Quality Management System (QMS).

To clarify chemical substances that should be prohibited from our products or identified, TDK has compiled in-house standards based on related industrial standards, such as the International Electrotechnical Commission’s IEC 62474 (Material Declaration for Products of and for the Electrotechnical Industry) and the Global Automotive Stakeholder Group’s Global Automotive Declarable Substance List.

As a components manufacturer in the middle of the supply chain, we implement this system thoroughly for prevention and control at each of these stages purchasing, manufacturing, and selling.

Purchasing (1) — Green procurement

We established the TDK Chemical Substance Contained for Product Standards to ensure that no regulated chemical substances are contained in our products. We also established the TDK Green Procurement Standards, requiring of suppliers that materials, parts, and packaging contain no regulated chemical substances.

In addition, we request suppliers to report chemical substances contained in their products that should be identified, including notification to them of information on substances of very high concern in the European Union’s Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) regulation.

Purchasing (2) — Incoming inspection

TDK carefully audits information provided by suppliers regarding chemical substances contained in materials, parts, and packaging, to verify compliance with the TDK Chemical Substance Contained for Product Standards.

To prevent the possibility of regulated chemical substances being present due to human error or other causes, in response to the risk level, TDK measures the amount of specific chemical substances contained in procured products through analytic tests conducted at the time of acceptance and prevents regulated chemical substances from entering the manufacturing process. Incidentally, the definition of risk level, frequency of measurements, and so on are continuously being revised based on performance.

Manufacturing (1) — Environment-conscious design and product assessment

As an industrial manufacturer, our basic approach to protecting the environment is to carefully assess all aspects of a product in the design and development stage. We believe that it is at this stage that a product’s effect in reducing the environmental load, in other words, its contribution to the goal of sustainable development and the circular society, is decided.

Environmental considerations are a key aspect of elevating quality. We see environment-conscious design and product assessment as a way to prevent later claims and complaints. In each of the various processes from procurement of parts and materials, to manufacturing, distribution, usage, and disposal, we identify elements that have particular bearing on the environment, and we promote the development of new and sometimes revolutionary technologies to realize improvements.

Manufacturing (2) — Preventing misuse, mix-ups and contamination

TDK has a framework in place to ensure that the use of banned substances is not tolerated, and to minimize the risk of misuse, mixing (including migration through contact, etc.), and contamination at mass production sites, such as in manufacturing processes, or at storage areas or warehouses. The measures taken consist of careful identification and control, separation, the establishment of procedures and standards, first-in and first-out practices, and controls for warehouse acceptance and dispatching.

In processes involving such equipment as solder tanks, where there is a possibility of contamination, we control lead levels using simplified test methods that have been developed jointly with solder manufacturers.

Selling (1) — Preventing shipment of non-compliant products

TDK supplies electronic components to customers in a wide range of industries, including not only the electric and electronic equipment business, in which the RoHS Directive is applied, but also the automotive, medical device, and other industries, and we have to meet various legal and customer requirements. In the case of the RoHS Directive, some customers desire products in compliance with the directive, and some customers not marketing in the European Union request products not conforming to the directive for the purpose of, for example, securing a higher level of product reliability.

To prevent non-compliant products from being shipped erroneously, we have registered RoHS Directive compliance data for all of the products in our sales management computer system. This system automatically checks orders against customer specifications both at the time of order acceptance and when issuing shipping instructions. When a product that does not comply with the RoHS Directive is to be shipped, an electronic “customer confirmation received” form must be completed before the product can be shipped.

Selling (2) — Information disclosure

TDK has in place a framework for disclosing information on chemical substances contained in its products that is tied to our efforts to ensure the non-use of chemical substances that TDK has banned. To respond promptly and accurately to inquiries from customers on chemical substances contained in products, we have implemented groupware to consolidate the management of processes extending from acceptance of customer inquiries by the sales departments to providing replies by the technical departments.