New Ferrite Material Used in High-Performance Noise Reduction Coil for Power Supplies

Information contained in the news releases are current as of the date of the press announcement, but may be subject to change without prior notice.

New Ferrite Material Used in High-Performance Noise Reduction Coil for Power Supplies

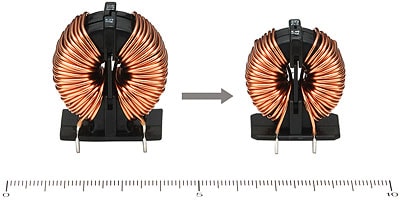

38% Smaller than Existing Coils with Same Characteristics,

60% Improvement in Characteristics Compared to Coils of the Same Size

is approximately 38% smaller than existing product. (left)

September 1, 2006

TDK Corporation announces the development and launch of a high-performance common-mode choke coil for use in power supply noise reduction. The coil employs a new ferrite material developed by TDK.

As electronic devices become smaller and incorporate advanced functions, the need for their power supplies to be made smaller and exhibit higher performance is increasing. Common-mode choke coils, key components in power supply noise reduction, are a major factor determining the size of power supplies. Coils can be miniaturized by using materials with high magnetic permeability, but the permeability of materials used in the past starts to drop off at frequencies below 100KHz and the high-permeability characteristics cannot be maintained at frequencies higher than 150KHz where noise control starts. As a result, miniaturizing and enhancing the performance of common-mode choke coils has been difficult.

The respond to market needs, TDK developed a new ferrite material with high magnetic permeability*1 and improved high-frequency characteristics for use in choke coils. TDK also optimized the shape and substantially improved the inductance characteristics and rated current. The result is a common-mode choke coil that achieves an approximately 38% reduction in volume and weight compared to existing coils with the same inductance properties and whose inductance properties are approximately 60% better than existing coils of the same size. In addition, the rated current is approximately 26% higher.

Applications for the new coils include a wide range of consumer electronics including air conditioners, lighting devices, PC, and liquid crystal televisions as well as information industry equipment. The new coils are ideal for devices that require high rated current and products that are under strong pressure for miniaturization.

The new coils are RoHS compliant and comply with domestic and overseas safety standards for electronic products*2

Supplementary Information

| *1 | Magnetic permeability: An indication of the ability of magnetic flux to pass through a material. The higher the magnetic permeability (i.e., the easier it is for magnetic flux to pass through) of ferrite materials used in choke coils and other components, the higher the inductance and the greater the noise reduction effects. |

| *2 | Compliance with safety standards does not mean that the products have been approved or certified. |

-

Main Features

-

- High inductance characteristics. Approximately 60% better than earlier products of the same size.

- Compact. Approximately 38% less volume and weight compared to earlier products with the same inductance.

- Complies with the RoHS .

- Complies with the safety standards if various countries including the DENAN Law, UL, and CSA standards*2.

-

Applications

- Noise countermeasure in CTVs, PDPs, LCDs, air conditioners (indoor and outdoor units), audio-visual equipment, inverter lights, and other electrical products that employ mains connectors.

-

Main Characteristics

-

* A horizontal type with the same characteristics is also available.Component Size [mm] Handling Power

(L·I2) [mH·A2]Rated Current

(A)Inductance

(mH)HF2316 23×16×20 10.5 0.2-3.0 1.2-145 HF2318 23×18×22 13 0.3-3.0 1.5-100 HF2922 29×22×28 29 0.5-3.0 3.2-100 TF1813V* 18×13×15 20 0.7-3.2 2.0-20 TF2518V* 25×18×27 50 2.5-10.0 0.65-9 TF2721V* 27×21×28 75 2.5-10.0 1.0-13 TF3020V* 30×20×31 130 3.0-20.0 0.35-13 TF3525V* 35×25×35 195 3.0-20.0 0.65-20 -

Production and Sales Plan

-

- Sample prices : 200 yen - 500 yen

- Country of production : China

- Production capacity : 1 million units/month

- Start of production : August 2006

For further information, contact the Corporate Communications Dept.

Tel.: 81-3-6778-1055

E-mail: TDK.PR@tdk.com