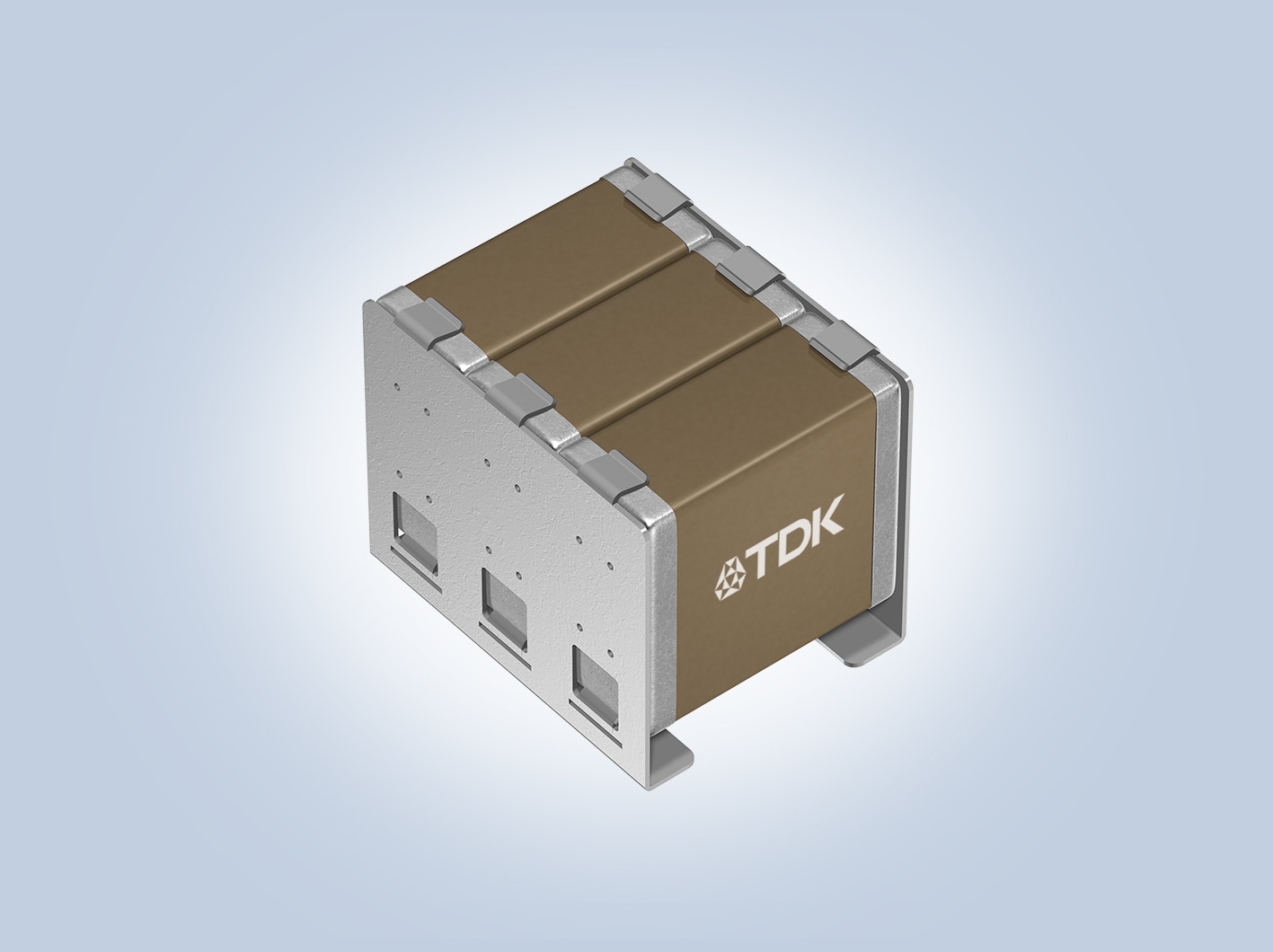

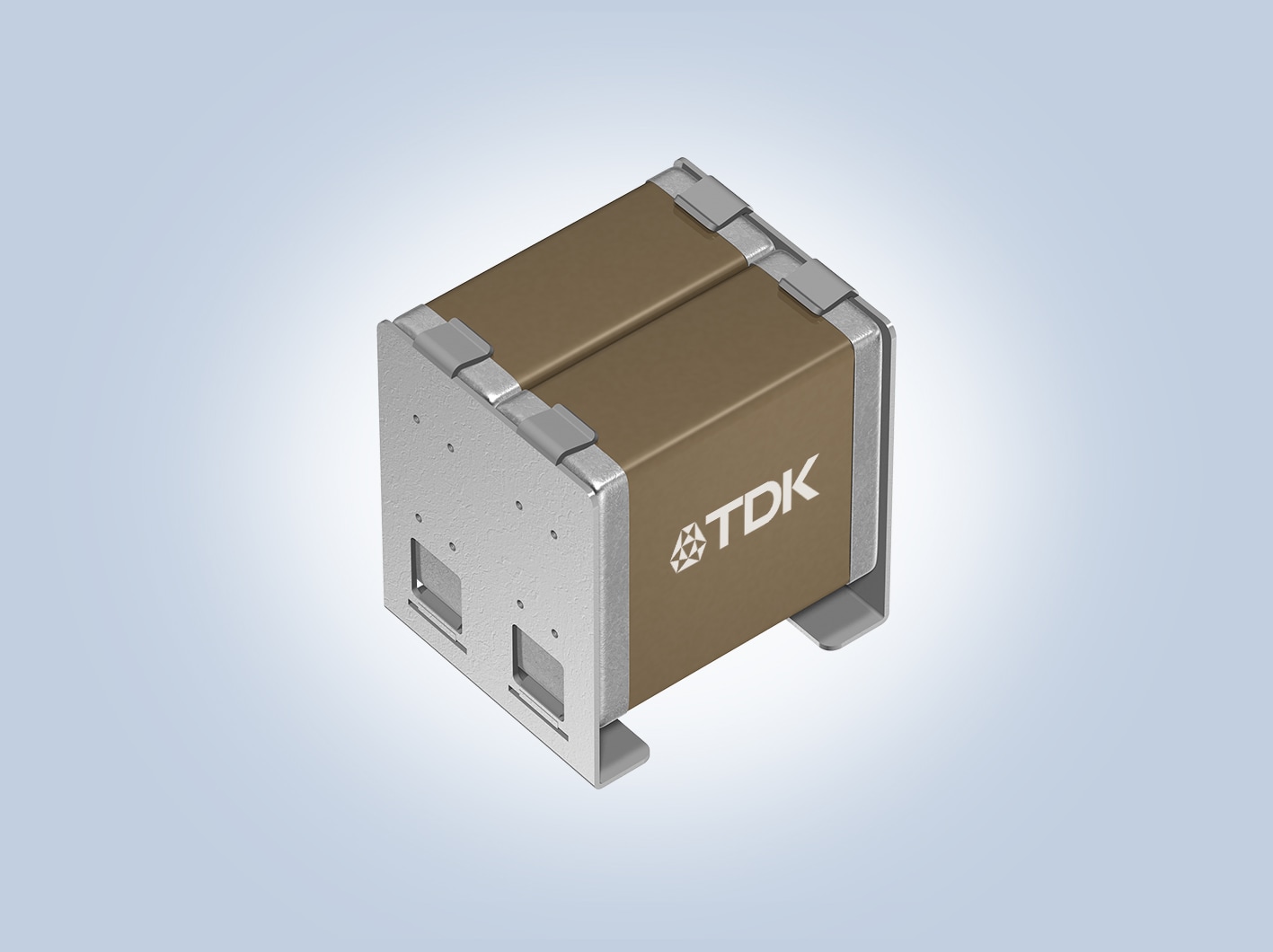

Multilayer Ceramic Capacitors: TDK expands inline structure and low-resistance type MEGACAP MLCCs with metal frames for automotive

- The automotive-grade inline structure MEGACAP MLCCs are qualified based on the automotive standard AEC-Q200

- Low resistance achieved by optimizing metal frame materials

- Lineup includes 99 nF/1000 V with Class 1 and 47 μF/100 V with Class 2 dielectric

TDK logo is not stamped on the actual product.

September 10, 2024

TDK Corporation (TSE:6762) has extended the automotive-grade CA series of its MEGACAP MLCCs with a metal frame. Mass production of the product series began in September 2024.

In recent years, the development of automobiles with electric powertrains, such as hybrid- (HEVs) and battery-electric vehicles (BEVs), and highly efficient charging technologies, has significantly progressed. Both help to reduce greenhouse gas emissions. In these applications, the power consumption of various subsystems including inverters, onboard chargers (OBCs), and wireless power transfer (WPT) systems is increasing, and MLCCs must handle high currents and have large capacitance.

To meet these needs, TDK developed the CA series, the largest MLCCs in the industry* (6.00 x 5.60 x 6.40 mm) with a metal frame and 3-line type structure. TDK now provides an extensive lineup including 99 nF/1000 V with a Class 1 dielectric and 47 μF/100 V with a Class 2 dielectric.

To handle high currents, TDK has reduced the equivalent series resistance (ESR) compared to the previous products by optimizing the materials of the metal frame. This helps reduce the number of components and miniaturizes devices. TDK will further expand its lineup to meet the needs of customers.

* As of September 2024, according to TDK

Main applications

- Smoothing and decoupling of the power lines

- Resonant circuits in subsystems such as OBCs and WPTs

- Snubber circuits in inverters

Main features and benefits

- Low resistance achieved by optimizing metal frame materials

- High capacitance achieved using multiple MLCCs to help reduce the number of components and miniaturizing devices

- High reliability qualified based on AEC-Q200

| Type | Outer dimensions [mm] (L x W x H) |

Type | Temperature characteristics | Rated voltage [V] |

Capacitance [F] |

|---|---|---|---|---|---|

| CAA572C0G3A203J640LJ | 6.00 x 5.60 x 6.40 | 2 - line | C0G | 1000 | 20 n |

| CAA572C0G3A303J640LJ | 6.00 x 5.60 x 6.40 | 2 - line | C0G | 1000 | 30 n |

| CAA572C0G3A443J640LJ | 6.00 x 5.60 x 6.40 | 2 - line | C0G | 1000 | 44 n |

| CAA572C0G3A663J640LJ | 6.00 x 5.60 x 6.40 | 2 - line | C0G | 1000 | 66 n |

| CAA573C0G3A993J640LJ | 6.00 x 8.40 x 6.40 | 3 - line | C0G | 1000 | 99 n |

| CAA572C0G2J204J640LJ | 6.00 x 5.60 x 6.40 | 2 - line | C0G | 630 | 200 n |

| CAA573C0G2J304J640LJ | 6.00 x 8.40 x 6.40 | 3 - line | C0G | 630 | 300 n |

| CAA572X7T2J105M640LJ | 6.00 x 5.60 x 6.40 | 2 - line | X7T | 630 | 1 µ |

| CAA573X7T2J155M640LJ | 6.00 x 7.50 x 6.40 | 3 - line | X7T | 630 | 1.5 µ |

| CAA572X6T2W225M640LJ | 6.00 x 5.00 x 6.40 | 2 - line | X6T | 450 | 2.2 µ |

| CAA573X6T2W335M640LJ | 6.00 x 7.50 x 6.40 | 3 - line | X6T | 450 | 3.3 µ |

| CAA572X7T2V225M640LJ | 6.00 x 5.00 x 6.40 | 2 - line | X7T | 350 | 2.2 µ |

| CAA573X7T2V335M640LJ | 6.00 x 7.50 x 6.40 | 3 - line | X7T | 350 | 3.3 µ |

| CAA572X7S2A336M640LJ | 6.00 x 5.00 x 6.40 | 2 - line | X7S | 100 | 33 µ |

| CAA573X7S2A476M640LJ | 6.00 x 7.50 x 6.40 | 3 - line | X7S | 100 | 47 µ |

| CAA572X7R1V107M670LJ | 6.25 x 5.00 x 6.70 | 2 - line | X7R | 35 | 100 µ |

| CAA573X7R1V157M670LJ | 6.25 x 7.50 x 6.70 | 3 - line | X7R | 35 | 150 µ |

| CAA572X7R1E107M670LJ | 6.25 x 5.00 x 6.70 | 2 - line | X7R | 25 | 100 µ |

| CAA573X7R1E157M670LJ | 6.25 x 7.50 x 6.70 | 3 - line | X7R | 25 | 150 µ |

Samples may be purchased from the product page that is displayed after clicking Type.

About TDK Corporation

TDK Corporation is a world leader in electronic solutions for the smart society based in Tokyo, Japan. Built on a foundation of material sciences mastery, TDK welcomes societal transformation by resolutely remaining at the forefront of technological evolution and deliberately “Attracting Tomorrow.” It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK‘s comprehensive, innovation-driven portfolio features passive components such as ceramic, aluminum electrolytic and film capacitors, as well as magnetics, high-frequency, and piezo and protection devices. The product spectrum also includes sensors and sensor systems such as temperature and pressure, magnetic, and MEMS sensors. In addition, TDK provides power supplies and energy devices, magnetic heads and more. These products are marketed under the product brands TDK, EPCOS, InvenSense, Micronas, Tronics and TDK-Lambda. TDK focuses on demanding markets in automotive, industrial and consumer electronics, and information and communication technology. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2024, TDK posted total sales of USD 14.6 billion and employed about 101,000 people worldwide.

Downloads

- Further information on the products can be found under

https://product.tdk.com/system/files/dam/doc/product/capacitor/ceramic/mlcc/catalog/mlcc_automotive_megacap_ca_en.pdf

Contacts for regional media

| Region | Contact | Phone | ||

|---|---|---|---|---|

| Japan | Mr. Daiki ITO | TDK Corporation Tokyo, Japan |

+813 6778-1055 | TDK.PR@tdk.com |

| ASEAN | Ms. Jiang MAN Ms. Pei Lu LEE |

TDK Singapore (Pte) Ltd. Singapore |

+65 6273 5022 | asean.inquiry@sg.tdk.com |

| Greater China | Ms. Clover XU | TDK China Co., Ltd. Shanghai, China |

+86 21 61962307 | TDK.PR-CN@tdk.com |

| Europe | Mr. Frank TRAMPNAU | TDK Management Services GmbH Duesseldorf, Germany |

+49 211 9077 127 | frank.trampnau@tdk.com |

| America | Ms. Sara M. LAMBETH | TDK Corporation of America Irving, TX, USA |

+1 972-409-4519 | sara.lambeth@us.tdk.com |