In a Nutshell: Unique materials informatics that powers DX at TDK

In recent years, materials informatics (MI) has been gaining global attention as a means to enhance the efficiency of materials development through the use of artificial intelligence (AI) and big data. Established with the aim of commercializing a magnetic material called ferrite, TDK has been working on MI since 2013 and has made materials technology its core technology. The development of AI-based data analysis software called “Aim” is one outcome of these efforts. We are excited to share a glimpse into TDK’s initiatives and future prospects with Aim as a force that drives the company’s digital transformation (DX) efforts.

DX in Materials Development: Materials informatics

Manufacturing companies across the world are increasingly more invested in MI. In the traditional process of materials development, experiments and simulations are performed, and the data obtained are analyzed, drawing on the knowledge and expertise of engineers. This process costs time, money, and human resources. But using AI to predict the properties and performance of a material allows us to explore new materials much faster at reduced cost. This truly is digital transformation (DX) of materials development.

Materials informatics: The concept

Aim: AI-Based data analysis software that accelerates TDK’s DX

TDK considers materials technology to be of its core technologies, and its advancement has been an important goal ever since the establishment of the company. TDK has been working on MI since 2013, and the efforts have led to the development of a new magnet material and prediction of dielectric loss for high-frequency material. One thing that has come to stand out in the course of these efforts is TDK’s industry-leading diverse product lineup. Since its establishment, TDK has developed a unique set of material technologies for each of its products, accumulating data analysis technologies along the way. There have been challenges, however, in that these technologies have been concentrated within various different business divisions and departments, making it difficult to deploy them at a company-wide level.

Aim is an AI-based data analysis software that was developed in 2018 to allow the data analysis technologies accumulated in individual departments to be deployed company-wide so that anyone can use them, and to amass high-quality data that are necessary for the use of AI and big data. With features such as “grain analysis,” “data analysis,” “image analysis,” and “object detection,” Aim allows for an easy analysis of images and data by simply importing them to the software. It evolves as more data is accumulated, and with big data, it potentially enables us to develop new materials at several times to multiple times the speed (hence the efficiency) compared to conventional methods.

How Aim looks on the web

AI Data Analysis Solution: Grain analysis used to take an hour to complete, now done in seconds

Aim was first released in 2019 as a web application on TDK's intranet. The tool was available for free use by its employees, including those based overseas. It can be accessed through a web browser, and it is easy for anyone to import data from a PC to Aim and store it on the database—it is as simple as drag and drop. Aim is also highly customizable, allowing it to be tailored to the specific needs of the development of materials for a wide range of products handled by TDK. Now many employees are using it, and data is being accumulated rapidly.

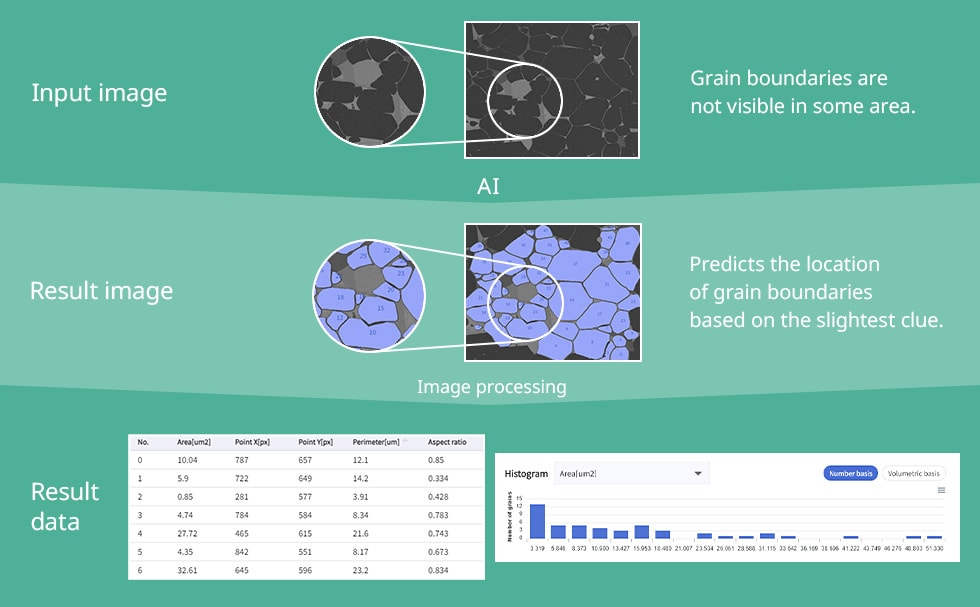

The use of Aim in materials development involves the inputting of both objective data, such as experimental data, image analysis data, and parameters based on the expertise and insights of materials developers, into Aim. The software then analyzes the data in procedures similar to those performed by skilled engineers and generates outcomes that are more stable than those achieved by manual methods. In the grain analysis of magnetic materials, for instance, it used to require a manual input of the boundaries between grains (i.e., grain boundaries) if they were unclear, which would take 30 to 60 minutes per image. With Aim, the software can predict the positions of grain boundaries, and complete the analysis in a matter of seconds.

Example of Aim uses: Grain analysis

Operation of Aim to Promote MI and Achieve DX within TDK

Following the enhancements of data analysis and database capabilities, TDK began the operation of Aim in April 2023 when it was ready to utilize MI. The operation is initially limited to research-specific divisions in Japan; eventually, it will be deployed at more locations both in Japan and overseas. As TDK verifies its effectiveness through operation and testing, it will continue developing more efficient MI mechanisms.

We spoke with two people from Technology & Intellectual Property HQ of TDK: Mr. Takanori Yamada, Section Head of the Advanced Products Development Center, who developed Aim and is now responsible for the operation and promotion of the software; and Dr. Yuji Umeda, Section Head of the Materials Research Center, who engages in the promotion of materials informatics.

“We have developed Aim to be a user-friendly tool little by little as we gathered feedback from in-house users, but it is still a work in progress. We have received many valuable opinions, and I personally have a lot of things to do with the software. There are so many places where we can take advantages of data—materials informatics being one of them. We will keep making improvements to make it more user-friendly and useful.” (Mr. Yamada)

“Materials informatics, including Aim, is a tool. By using this tool, I believe we can accelerate materials development, ultimately leading to significant advancements in TDK’s materials technology. And for us to master the use of this tool, materials engineers will become even more crucial. We will continue to work on building and establishing MI mechanisms to drive DX of our development activities.” (Dr. Umeda)

Section Head, Sec. No.3, Software Solutions Development Department, Advanced Products Development Center, Technology and Intellectual Property HQ, TDK Corporation

Yuji Umeda (right)

Section Head, Materials Research Section No.5, Materials Research Center, Technology and Intellectual Property HQ, TDK Corporation

TDK is promoting in-house DX in materials development through the operation of Aim, among other means, thereby accelerating the promotion of MI. By further advancing its proprietary materials technologies, TDK is committed to contributing to society with its valuable products and technologies.