Sustainability | Environment | Goals and Achievements

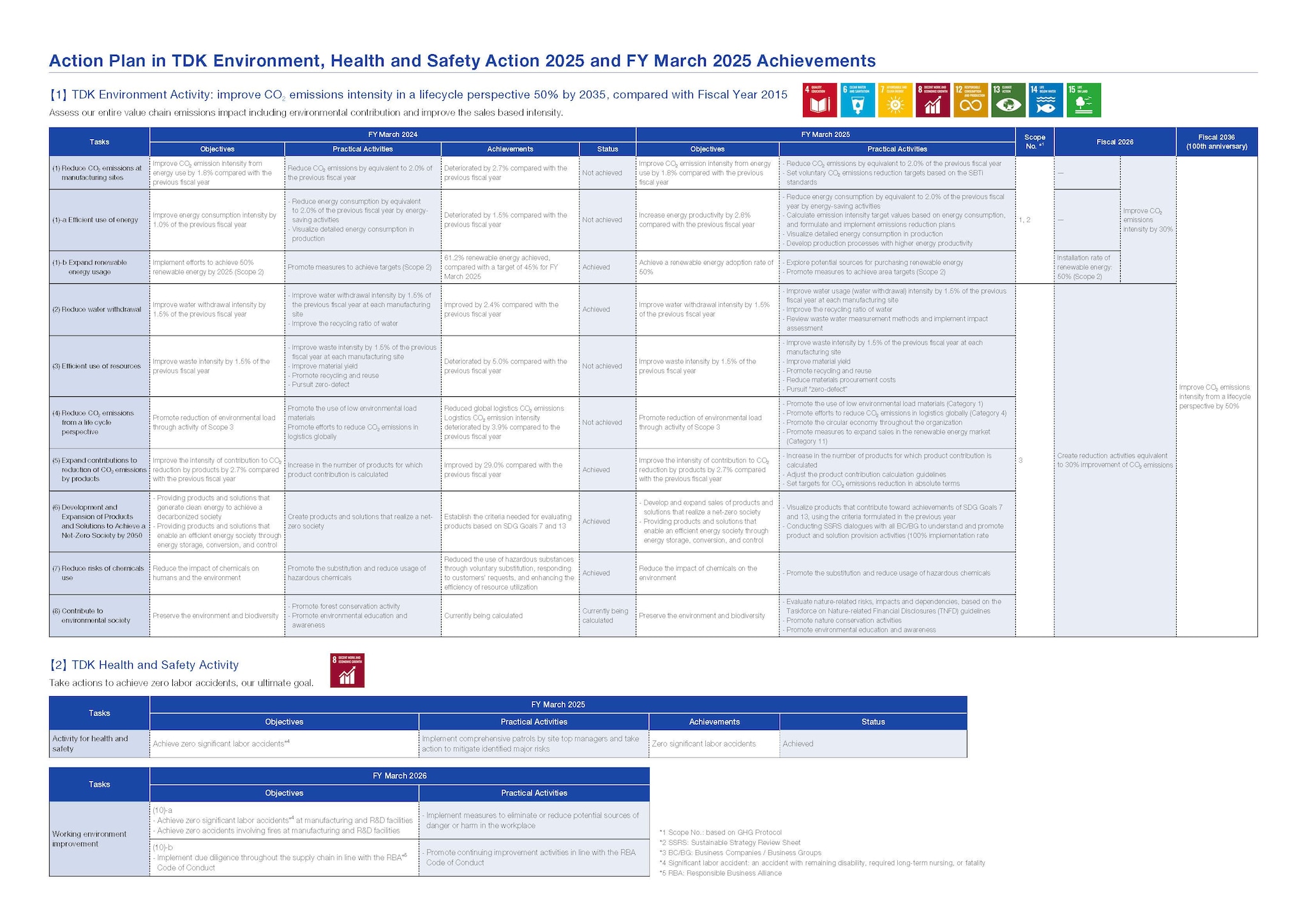

Action Plan in TDK Environment, Health and Safety Action 2025* and FY March 2025 Achievements

Established: April 1, 2016

Revised: April 1, 2025

*Action Plan in TDK Environment, Health and Safety Action 2025 runs through FY March 2026 (ending March 31, 2026).

Action Plan in TDK Environment, Health and Safety Action 2025* and FY March 2025 Achievements PDF