Business creation starting from social issues

ATL Contributes to Renewable Energy Society with Residential Energy Storage Systems.

The TDK Group’s Amperex Technology Ltd. (ATL) is engaged in the

development, manufacture, and sale of lithium-ion batteries.

Thanks to its design and development of new materials, new cell

and pack structure, and automated production processes and

equipment, ATL makes excellent products. ATL’s strengths lie in

its innovative battery technology, customer-first philosophy,

advanced product design, superior technical skills, world class

production capacity, swift order processing, and unparalleled

customer services into practice.

The rechargeable lithium-ion batteries manufactured by ATL technically can replace almost all types of primary battery in household electric appliances, e.g. remote control console. Multiple primary batteries may be consumed in the life time of appliances, but usually one rechargeable battery is enough. It is very likely that one rechargeable battery can replace multiple pieces of primary batteries. Since most non-rechargeable primary batteries after use end up being buried in landfill as solid wastes, replacing primary batteries by rechargeable lithium-ion batteries can contribute to reducing the amount of solid waste.

Among ATL’s battery products, the Residential Energy Storage Systems (RESS) in particular can contribute toward achieving Target 7.2 of the Sustainable Development Goals (SDGs), which is to “By 2030, increase substantially the share of renewable energy in the global energy mix.”

An RESS is a large-scale battery that stores electricity generated at home by means of photovoltaic panels or wind turbines. In ordinary homes, there is a striking tendency for energy consumption to be low in daytime, when family members are out at work or school, and then to high in the evening after their return home. Since solar energy is only generated in the daytime, there is a time lag between generation and consumption. An RESS makes it possible to store electricity generated in daytime for use in the evening. There are inevitably cloudy and rainy days in which solar energy cannot be generated, the electricity stored in RESS can help homes get through them.

By supplying RESSs at a reasonable price together with excellent service, we can increase the ratio of renewable energy used in homes and contribute to the realization of a renewable energy society.

Our mission at ATL is to expand the use of renewable energy through the supply of excellent energy storage systems. Regarding the realization of a carbon-free society, a challenge for us going forward is the reduction of our own CO₂ emissions. We are investigating CO₂ emissions in the entire product lifecycle, from the procurement of materials to the manufacture, supply, and disposal of batteries and are searching for ways to reduce them. At the same time, we are making efforts to research the recycling and reuse of spent batteries.

We believe that both corporate growth and a sustainable society can be realized. Various countries and companies have already announced their carbon-neutral plans. For ATL, which supplies products contributing to the reduction of CO₂ emissions, we see this also as a chance for growth and will continue to make all kinds of efforts.

Joe Kit Chu Lam

Executive Vice President

Amperex Technology Limited

TDK Electronics cuts CO₂ emissions in half

TDK Electronics takes its responsibility toward society and the environment very seriously. At our facilities around the world, we constantly strive to improve energy efficiency, save energy wherever possible and use electricity from renewable sources.

We also focus strongly on products that help protect the environment and yield benefits for society. Among our staff, we foster an awareness that not only our technologies and solutions but also our behavior can play a part in realizing the social, economic and ecological goals of the global community. The Sustainable Development Goals (SDGs) provide useful guidance to this end.

Thanks to projects in India and China, TDK Electronics was able to shave a good 96,000 tons off its CO₂ emissions by the turn of the fiscal year in April 2021 – a reduction of around 50 percent. The Nashik plant, where a photovoltaic installation on the roof of a production hall has covered about 5 percent of the factory’s electricity needs since 2019, now plans to increase this share to a total of 50 percent. To do so, the site is cooperating with a partner whose photovoltaic field can deliver peak output of 7,000 kWp and will supply solar power exclusively to the Nashik facility. In China, the Zhuhai FTZ and Hongqi factories began to source all their electricity needs from renewables for the first time in September 2020. This arrangement will initially run until the end of 2021. TDK Electronics has thus increased its share of renewable energy usage in Asia to more than 70 percent – making a tangible contribution to the three SDGs on which the company is primarily focused: SDG 7 (affordable and clean energy), SDG 12 (responsible consumption and production) and SDG 13 (climate action).

Dr. Klaus Moertl

Head of Environmental Protection / Occupational Safety and CSR Coordinator

TDK Electronics

When the Covid-19 pandemic broke out, the attention of the world shifted to the United Nations’ third stated aim: good health and well-being – ensuring healthy lives and promoting well-being for all at all ages.

Many of our factories have since launched a variety of projects to support the healthcare systems in their countries. In Germany, for example, TDK Electronics gave 50,000 face masks to the Red Cross. The Szombathely facility in Hungary donated a mobile ultrasound scanner to a local hospital to help diagnose lung diseases and Covid-19 infections without having to move patients elsewhere.

Yet our own products too contribute to promoting human health and well-being. The Berlin plant in Germany, for example, manufactures pressure sensors for ventilators and anesthetic equipment from various producers. In ventilators, these sensors enable the flow of oxygen to be controlled and its pressure to be measured. Capacitors, inductors, varistors and all kinds of other passive components are also needed in ventilators.

Manuel Lumpe

Head of TPS Pressure Sensors Business Unit, Berlin

TDK Electronics

The special ceramic disks manufactured at Deutschlandsberg in Austria are another example of a medical technology product from TDK Electronics. The disks are used in the treatment of cancer patients, helping to interrupt the division of cancerous cells by means of low-intensity alternating electric fields. Fully automated volume production of the disks takes place at the Deutschlandsberg plant, which was specially accredited in 2018 in accordance with ISO 13485. This norm covers quality systems for the design and manufacture of medical-grade products.

Harald Kastl

Head of PPD Piezo Automotive Electronics / Industrial Electronics Business Unit, Deutschlandsberg

TDK Electronics

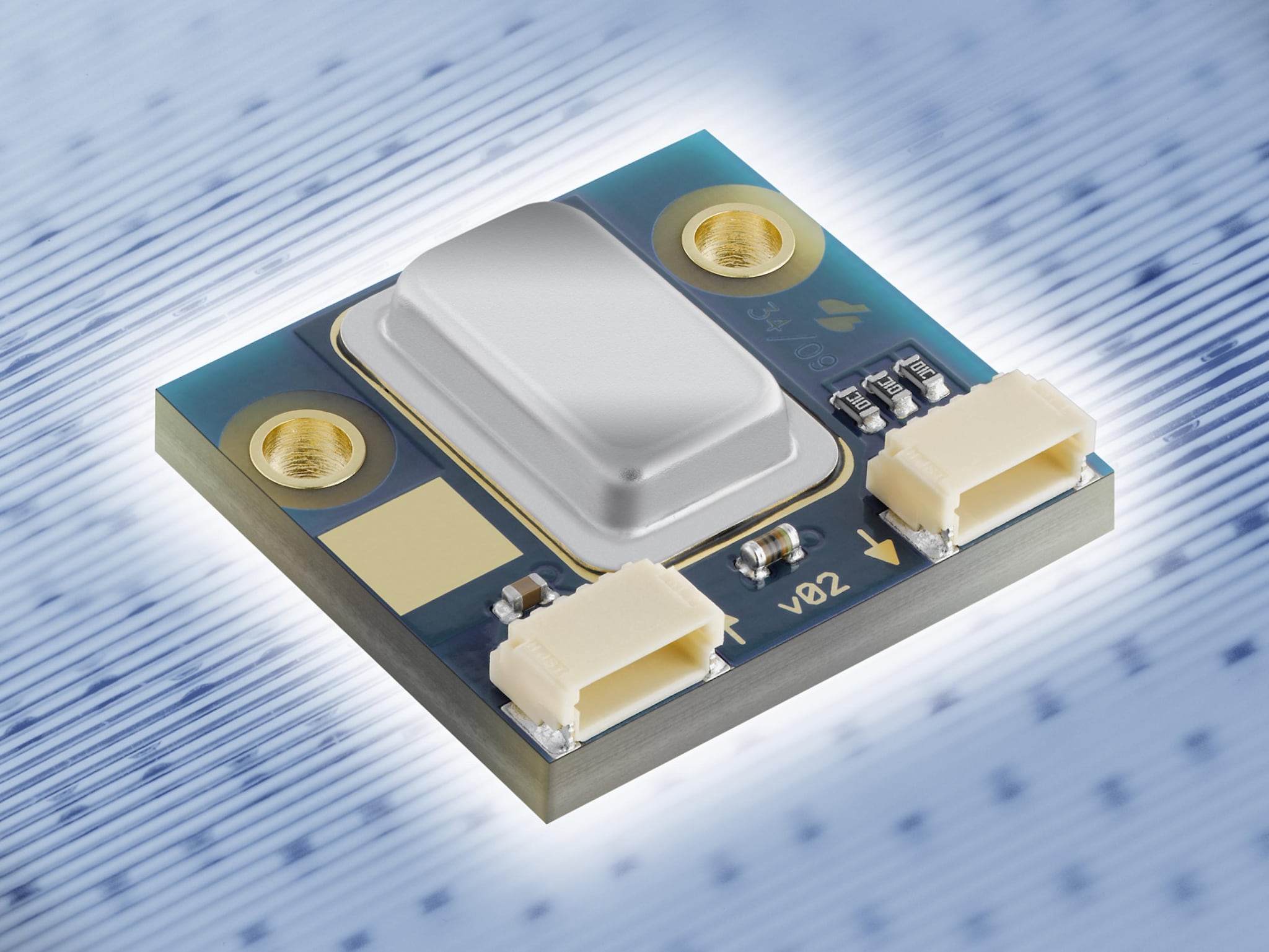

InvenSense’s Ultrasonic Time-of-Flight Sensors Contribute to Eradication of Infectious Diseases Like Covid-19

InvenSense is engaged in the development, manufacture, and sale of inertial sensors. In addition to sensor units, though, InvenSense also supplies solutions including firmware, drivers, applications, and reference design, thereby substantially cutting the time taken for customers to launch products on the market.

InvenSense is putting priority on efforts to contribute to the achievement of Target 3.3 of the Sustainable Development Goals (SDGs), which is to “By 2030, end the epidemics of AIDS, tuberculosis, malaria and neglected tropical diseases and combat hepatitis, water-borne diseases and other communicable diseases.”

Because of the Covid-19 pandemic, the world has greatly changed. The maintenance of social distancing and tracking of people who have been in contact with infected persons are playing an important role in curbing infection. Utilizing high-performance ultrasonic 3D sensing of Chirp, a subsidiary of TDK, Time-of-Flight (ToF) sensors supplied by InvenSense measure the distance from others precisely in units of a centimeter. When the minimum social distance is exceeded, they issue an alert and measure the duration of contact. At the same time, while protecting individual privacy, they record the distance from others and contact time. If the user is confirmed to be infected, persons who have been in contact can be tracked and notified, thereby narrowing the target and curbing the spread of infection. Safe workplace environments can be realized if employees wear these ultrasonic ToF sensors.

Currently ultrasonic ToF sensors use straps, so it is necessary

to wear two units, one on the front of the body and one on the

back. As improvements going forward, InvenSense is hoping to

implant sensors seamlessly in clothing and to extend battery

life.

We also believe that by further strengthening system security,

it will be possible to broaden the scope of use to include, for

example, urban areas.

To extend the wearability of ultrasonic ToF sensors, research is

needed on improvement of chip power consumption, system

integration, and high-grade packaging. These are domains in which

TDK possesses cutting-edge technology, so improvements can be made

by utilizing these strengths.

As regards security, it is necessary to consider system design in

general and all information that identifies the wearer. On this

point, by analyzing all kinds of obstacles, we think that security

can be ensured.

We believe that corporate growth is impossible without

contributing to the SDGs. Decision making for InvenSense’s

products, design, and manufacturing places importance on reducing

the amount of materials and resources used, improving the

processing capabilities of equipment, cutting power consumption in

manufacturing, and boosting efficiency. We employ the design

process in manufacturing and testing and practice it using the

latest Industry 4.0 machine-learning methods.

While substantially expanding our business, InvenSense is also

making relentless efforts to maintain the amount of resources used

and cut CO₂ emissions.

Dr. Peter Hartwell

Chief Technology Officer

InvenSense