TDK Starts Mass Production of Industry's First* High-Capacitance, 3-Terminal Feed Through Multilayer Ceramic Chip Capacitor

Information contained in the news releases are current as of the date of the press announcement, but may be subject to change without prior notice.

TDK Starts Mass Production of Industry's First* High-Capacitance, 3-Terminal Feed Through Multilayer Ceramic Chip Capacitor

Single-Chip Design Contributes to Reducing Number of Components

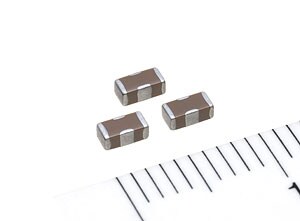

3-Terminal Feed Through Multilayer Ceramic Chip Capacitor

August 6, 2007

TDK Corporation announced today that it has developed a high-capacitance, 3-terminal feed through multilayer ceramic chip capacitor (CKD310JB0J226M). Production began in July.

As electronic devices such as personal computers and mobile terminal devices become smaller even as they incorporate more advanced functions, makers are making increasing demands for smaller and fewer components in order to save space. In response to these demands, TDK employed its materials and multilayering technologies-two of its areas of specialization-to raise the capacitance of 3-terminal, feed through capacitors and develop a one-chip, high-capacitance, low ESL feed through multilayer ceramic chip capacitor with noise elimination effects over a wide bandwidth.

Compared to 2-terminal capacitors, 3-terminal, feed through capacitors have low ESL and high attenuation in high-frequency ranges. By making improvements in design and process technologies achieved through the use of simulation technology, TDK developed a high-capacitance, 3-terminal, feed through capacitor with a capacitance of 22 µF in the same size as earlier products (dimensions: 3.2 mm × 1.6 mm × 1.3 mm) to shift the resonance point to a lower frequency, thereby achieving noise elimination effects over a wide bandwidth. As a result of these properties, this product is effective for IC power supply decoupling and at smoothing DC/DC converter input and output. In addition, the internal electrodes are nickel and a multilayer design is used, achieving low R-DC (direct current resistance) and a rated current of 4 A.

Previously, a smoothing circuit required one unit made up of two or three 1.6 mm × 0.8 mm sized 2-terminal capacitors with a capacitance of 10 µF and a 1.0 mm × 0.5 mm sized capacitor with a capacitance of 0.1 µF, but just one of this product provides the same properties. This allows for a substantial reduction of component mounting area and supports the miniaturization of the high-frequency circuits of various devices as well as the incorporation of advanced functions.

- * As of July 15, 2007, according to TDK investigations.

-

Glossary

-

- ESL : Equivalent series inductance. If the ESL is high, noise elimination effects in the high-frequency range are reduced.

- 3-terminal feed through capacitor : 2-terminal capacitors have one terminal on the ground side, but 3-terminal capacitors have two, which reduces the ESL.

-

Main Features

-

- The same size as earlier products of the same type (dimensions: 3.2 mm × 1.6 mm × 1.3 mm), but has 10 times the capacitance (22 µF) of TDK mass production products. The industry's highest capacitance product of its type.

- Multiple capacitors (the previous configuration) have been integrated in a single chip.

- Lead-free and suitable for mounting with lead-free solder; RoHS compliant.

- Product specification: Capacitance 22 µF, rated voltage 6.3 V, allowable current 4 A

-

Production and Sales Plan

-

- Sample price : 30 yen per unit

- Production location : Akita region

- Production capacity : 3 million units/month

- Start of production : July 2007

For further information, contact the Corporate Communications Dept.

Tel.: 81-3-6778-1055

E-mail: TDK.PR@tdk.com