Inductors: TDK offers high-current and low DC resistance power inductors supporting temperatures of up to 150 °C for automotive power circuits

- The inductors for automotive power circuits have high magnetic shield construction that enables high-density mounting

- Higher current and lower DC resistance were achieved by optimizing the ferrite core with TDK’s metallic magnetic material for the magnetic shielding function

- Supports an operating temperature range of -40 to +150 ℃ (including self-heating)

- Compliant with AEC-Q200 and RoHS

October 25, 2022

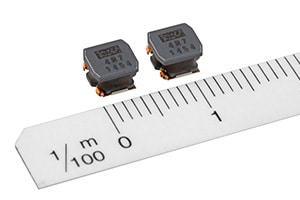

TDK Corporation (TSE: 6762) has announced the introduction of its new VLS5030EX-D type power inductor (5.3 x 5.0 x 3.0 ㎜ (L x W x H)) as part of the VLS-EX-D Series of wound ferrite power inductors automotive power circuits. These compact components provide excellent DC superposition characteristics with an assured performance at temperatures of up to 150 ℃. These inductors are suitable for headlights, airbags, electric power steering (EPS), advanced driver-assistance systems (ADAS), engine control units (ECUs), and various other power circuit applications. Mass production of these new inductors began in October 2022.

Recently, there has been a rise in the number of ECUs mounted under the hood for the electrification of various automotive control functions, as well as for infotainment, autonomous driving, and other applications. The compact components support automotive power over-coax (PoC) implementations with an excellent DC superposition characteristic for transmitting data as well as supplying power, fulfilling the needs of, for example, advanced driver-assistance systems (ADAS) that employ low-voltage differential signaling (LVDS) transmission. In addition, as the IC's processing capability increases, a higher current is required, and the VLS-EX-D series contributes to these specifications.

The new VLS-EX-D series of inductors achieves a higher-rated current compared to TDK’s standard VLS-EX-H series. These improvements are achieved by using TDK’s innovative metallic magnetic material for the magnetic shielding function. Specifically, for the VLS5030EX-D inductor, the rated Isat is 3.3 A at 4.7 μH, which is an increase of approximately 6 % from standard parts of the same size - 5.3 x 5.0 x 3.0 ㎜ (L x W x H). Moreover, thanks to the welding method used for connecting the wire winding to the external electrodes, high reliability is implemented for reflow and use in high-temperature environments.

TDK will continue expanding the VLS-EX-D series product portfolio to cater to needs for a wide range of automotive applications, centering on ADAS, and will meet the requirements of customers.

Glossary

- Isat: Saturation current value at which an inductance reduction of 30% below the initial inductance value occurs

Main applications

- Automotive power supply circuits for ADAS, EPS, PoC, various types of ECU, etc.

Main features and benefits

- Supporting temperatures of up to 150 ℃ for under-the-hood power circuit applications

- Implementing a DC superposition characteristic with high-rated current by using TDK’s innovative metallic magnetic material for the magnetic shielding function

- Achieving high reliability by employing the wire connection structure in which wires and terminals are welded

- Compliant with AEC-Q200 Rev D for automotive applications

Key data

| Type | Inductance [μH] |

DC resistance [Ω]typ. |

Rated current* Isat [A]max. |

Rated current Isat [A]typ. |

Rated current Itemp [A]typ. |

|---|---|---|---|---|---|

| VLS5030EX-4R7M-D | 4.7±20% | 0.040±20% | 3.3 | 3.7 | 3.4 |

The rated current shall be Isat or Itemp, whichever is less.

- Isat: Current value based on inductance variation (30% lower than the initial inductance value)

- Itemp: Current value based on temperature increase (Temperature increase of 40 ℃ by self-heating)

*Itemp varies depending on the usage environment (board specifications, mounting density, etc.)

About TDK Corporation

TDK Corporation is a world leader in electronic solutions for the smart society based in Tokyo, Japan. Built on a foundation of material sciences mastery, TDK welcomes societal transformation by resolutely remaining at the forefront of technological evolution and deliberately “Attracting Tomorrow.” It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK‘s comprehensive, innovation-driven portfolio features passive components such as ceramic, aluminum electrolytic and film capacitors, as well as magnetics, high-frequency, and piezo and protection devices. The product spectrum also includes sensors and sensor systems such as temperature and pressure, magnetic, and MEMS sensors. In addition, TDK provides power supplies and energy devices, magnetic heads and more. These products are marketed under the product brands TDK, EPCOS, InvenSense, Micronas, Tronics and TDK-Lambda. TDK focuses on demanding markets in automotive, industrial and consumer electronics, and information and communication technology. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2022, TDK posted total sales of USD 15.6 billion and employed about 117,000 people worldwide.

Downloads

- Further information on the products can be found under

https://product.tdk.com/system/files/dam/doc/product/inductor/inductor/smd/catalog/inductor_automotive_power_vls5030ex-d_en.pdf

Contacts for regional media

| Region | Contact | Phone | ||

|---|---|---|---|---|

| Japan | Mr. Daiki ITO | TDK Corporation Tokyo, Japan |

+813 6778-1055 | TDK.PR@tdk.com |

| ASEAN | Ms. Jiang MAN Ms. Pei Lu LEE |

TDK Singapore (Pte) Ltd. Singapore |

+65 6273 5022 | TDK.ASEAN-inquiry@tdk.com |

| Greater China | Ms. Clover XU | TDK China Co., Ltd. Shanghai, China |

+86 21 61962307 | TDK.PR-CN@tdk.com |

| Europe | Mr. Frank TRAMPNAU | TDK Management Services GmbH Duesseldorf, Germany |

+49 211 9077 127 | frank.trampnau@tdk.com |

| America | Ms. Sara M. LAMBETH | TDK Corporation of America Irving, TX, USA |

+1 972-409-4519 | sara.lambeth@tdk.com |