Multilayer ceramic chip capacitors: Soft-termination MLCCs with low ESR

- Low ESR comparable to conventional MLCCs

- High mechanical robustness to protect against board flexure

- Suitable for battery lines in automotive and industrial robot applications

Apr 17, 2018

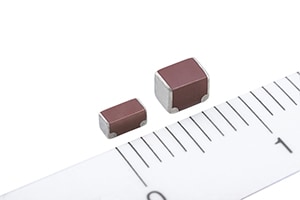

TDK Corporation has developed the industry’s first soft-termination MLCCs with low ESR. The new CN series features terminal electrodes with a conductive resin layer that provides high mechanical robustness to protect against board flexure. At the same time, the new MLCCs offer a low ESR that is comparable to that of conventional MLCCs. The CN series offers capacitance values ranging from 2.2 µF to 22 µF and rated voltages from 16 V to 100 V. Based on X7R dielectric material commercial grade and automotive grade types of the new MLCCs are available. The latter are qualified to AEC-Q200. Mass production and sales of the first types was launched in April 2018.

Soft-termination MLCCs, which are able to withstand the stress from board flexure, are an effective way to prevent short circuits when used in battery lines. Conventional designs that coat the electrodes completely with resin, however, lead to higher ESR and losses. TDK has achieved the low terminal resistance values by applying the conductive resin layer only where the terminal electrode comes into contact with the PCB. Thanks to the low resistance of the terminal electrodes of the new CN series these MLCCs are suitable for battery lines in automotive and industrial robot applications, where they help to improve system reliability. The capacitors can also be used in automotive ECUs, advanced driver assistance systems (ADAS), and automated driving systems. TDK offers a broad portfolio of MLCCs for a wide range of applications. TDK will continue to place a special focus on the development of technologically superior automotive grade MLCCs.

Main applications

-

- Battery lines of automotive and industrial robot applications

- Automotive ECUs

- Advanced driver assistance systems (ADAS), automated driving systems

Main features and benefits

-

- Low ESR comparable to that of conventional MLCCs

- High mechanical robustness to protect against board flexure

- Qualified to AEC-Q200

Key data

| Type | Temperature characteristic | Rated voltage [V] | Capacitance[µF] | Dimensions [mm] |

|---|---|---|---|---|

| CN*6P1X7R2A475K 1) | X7R | 100 | 4.7 | 3.2 x 2.5 x 2.5 |

| CN*5L1X7R1N225K 1) | 75 | 2.2 | 3.2 x 1.6 x 1.6 | |

| CN*6P1X7R1H106K 1) | 50 | 10 | 3.2 x 2.5 x 2.5 | |

| CN*6P1X7R1H475K 1) | 4.7 | 3.2 x 2.5 x 2.5 | ||

| CN*5L1X7R1H475K 1) | 3.2 x 1.6 x 1.6 | |||

| CN*5L1X7R1H225K 1) | 2.2 | 3.2 x 1.6 x 1.6 | ||

| CN*5L1X7R1C106K 1) | 16 | 10 | 3.2 x 1.6 x 1.6 | |

| CN*6P1X7R1E226K 2) | 25 | 22 | 3.2 x 2.5 x 2.5 | |

| CN*5L1X7R1E106K 2) | 10 | 3.2 x 1.6 x 1.6 |

*Placeholder for either of the following: A = Automotive grade; C = Commercial grade

1) Production begin: April 2018

2) Production begin: July 2018 and onward

About TDK Corporation

TDK Corporation is a leading electronics company based in Tokyo, Japan. It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK's portfolio includes passive components, such as ceramic, aluminum electrolytic and film capacitors, ferrites and inductors, high-frequency products, and piezo and protection components, as well as sensors and sensor systems and power supplies. These products are marketed under the product brands TDK, EPCOS, InvenSense, Micronas, Tronics and TDK-Lambda. TDK's further main product groups include magnetic application products, energy devices, and flash memory application devices. TDK focuses on demanding markets in the areas of information and communication technology and automotive, industrial and consumer electronics. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2017, TDK posted total sales of USD 10.5 billion and employed about 100,000 people worldwide.

Downloads

- Further information on the products can be found under

product.tdk.com/info/en/catalog/datasheets/mlcc_automotive_soft_cna_en.pdf and

product.tdk.com/info/en/catalog/datasheets/mlcc_commercial_soft_cnc_en.pdf.

Contacts for regional media

| Region | Contact | Phone | ||

|---|---|---|---|---|

| Japan | Mr. Yoichi OSUGA | TDK Corporation Tokyo, Japan |

+813 6778-1055 | TDK.PR@tdk.com |

| ASEAN | Ms. Jiang MAN Ms. Pei Lu LEE |

TDK Singapore (Pte) Ltd. Singapore |

+65 6273 5022 | TDK.ASEAN-inquiry@tdk.com |

| Greater China | Ms. Clover XU | TDK China Co., Ltd. Shanghai, China |

+86 21 61962319 | TDK.PR-CN@tdk.com |

| Europe | Mr. Frank TRAMPNAU | TDK Europe GmbH Duesseldorf, Germany |

+49 211 9077 127 | frank.trampnau@eu.tdk.com |

| America | Ms. Sara M. LAMBETH | TDK Corporation of America Irving, TX, USA |

+1 972-409-4519 | sara.lambeth@tdk.com |