Multilayer ceramic chip capacitors:Automotive-grade soft-termination and MEGACAP Type MLCCs with C0G characteristics

- Capacitance drift of only 0.3 percent over a temperature range from -55 ºC to +125 ºC

- High capacitance stability at a high DC bias

- Qualified to AEC-Q200

Nov. 29, 2016

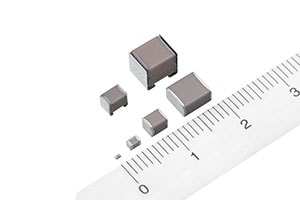

TDK Corporation has expanded its lineup of automotive-grade soft-termination and MEGACAP Type MLCCs with new C0G types. Until now, these robust MLCC designs, which offer effective protection against board flexure and solder cracks, have been available with X5R, X7R and X8R dielectric materials. The new types combine the low relative permittivity of the C0G dielectric with rated capacitance values up to 300 nF and enable MLCCs to be used in an even greater range of applications where reliability is required. Their rated voltages range from 50 V to 3000 V.

The new MLCCs feature high capacitance stability at a high DC bias. Moreover, the capacitance drift is only 0.3 percent over a broad temperature range from -55 ºC to +125 ºC, making the new Class 1 MLCCs especially well-suited for the high-precision resonant circuits for fast and efficient automotive wireless charging and in LLC resonant circuits of onboard chargers for plug-in hybrid and electric vehicles. The new types are qualified to AEC-Q200. In addition to the expanded range of automotive applications, the new C0G MLCCs are also suitable for use in circuits requiring high reliability or as replacements for other types of capacitors. Mass production and sales of the new components will begin in December 2016.

Glossary

-

- C0G: A dielectric material with a temperature characteristic in which capacitance changes within only 0.3% over a temperatures range from -55 ºC to 125 ºC.

- Class 1 ceramic capacitors: Offer high stability and low losses for resonant circuit applications.

- Soft termination: The terminal electrode of standard products consists of three layers: copper (Cu), nickel (Ni), and tin (Sn). The terminal electrode of soft-termination products consists of four layers, with a resin layer inserted between the copper and the nickel to protect against board flexure cracks, solder cracks from thermal shocks.

- MEGACAP Type: An MLCC design with metal lead frames attached to both ends of an MLCC to protect against board flexure cracks, solder cracks from thermal shocks. MEGACAP Type MLCCs are available in two basic designs: the single type and the stacked type.

Main applications

-

- Wireless chargers for electric vehicles

- LLC resonant circuits of onboard chargers for plug-in hybrid and electric vehicles

- Circuits that require high reliability (time constant circuits, filter circuits, resonant circuits, oscillation circuits, snubber circuits, etc.)

Main features and benefits

-

- Capacitance drift of only 0.3 percent over a temperature range from -55 ºC to +125 ºC

- High capacitance stability at a high DC bias

- Effective protection against board flexure and solder cracks

- Qualified to AEC-Q200.

Key data

-

Soft-termination MLCCs with resin terminal electrode layer Series Case size [IEC] Rated voltage [V] Max. capacitance [nF] CGA2 1005 (EIA 0402) 50,100 1 CGA3 1608 (EIA 0603) 50 to 250 10 CGA4 2012 (EIA 0805) 20 to 450 33 CGA5 3216 (EIA 1206) 50 to 630 100 CGA6 3225 (EIA 1210) 100 to 1000 68 CGA8 4532 (EIA 1812) 630,3000 33 CGA9 5750 (EIA 2220) 100 to 630 150 MEGACAP Type MLCCs with metal lead frames Series Case size [IEC] Rated voltage [V] Max. capacitance [nF] CKG32K 3225 (EIA 1210), single type 100 to 1000 68 CKG45K 4532 (EIA 1812), single type 250 to 630 68 CKG57K 5750 (EIA 2220), stacked type 250 to 630 150 CKG45N 4532 (EIA 1812), single type 250 to 630 140 CKG57N 5750 (EIA 2220), stacked type 250 to 630 300

About TDK Corporation

TDK Corporation is a leading electronics company based in Tokyo, Japan. It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK's portfolio includes electronic components, modules and systems* marketed under the product brands TDK and EPCOS, power supplies, magnetic application products as well as energy devices, flash memory application devices, and others. TDK focuses on demanding markets in the areas of information and communication technology and consumer, automotive and industrial electronics. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2016, TDK posted total sales of USD 10.2 billion and employed about 92,000 people worldwide.

- * The product portfolio includes ceramic, aluminum electrolytic and film capacitors, ferrites, inductors, high-frequency components such as surface acoustic wave (SAW) filter products and modules, piezo and protection components, and sensors.

Downloads

- Product with background (jpg: 1.3 MB; 96dpi)

- Product without background (jpg: 2.2 MB; 96dpi)

- Press release (pdf: 62.4 KB; )

- Press release (rtf: 185.0 KB; )

Contacts for regional media

| Region | Contact | Phone | ||

|---|---|---|---|---|

| Japan | Mr. Sumio MARUKAWA | TDK Corporation Tokyo, Japan |

+813 6778-1055 | TDK.PR@tdk.com |

| ASEAN | Ms. Jiang MAN Ms. Pei Lu LEE |

TDK Singapore (Pte) Ltd.Singapore | +65 6273 5022 | TDK.ASEAN-inquiry@tdk.com |

| Greater China | Ms. Jojo ZHOU | TDK China Co., Ltd. Shanghai, China |

+86 21 61962319 | TDK.PR-CN@tdk.com |

| Europe | Mr. Frank TRAMPNAU | TDK Europe GmbH Duesseldorf, Germany |

+49 211 9077 127 | frank.trampnau@eu.tdk.com |

| America | Ms. Sara M. LAMBETH | TDK Corporation of America Irving, TX, USA |

+1-972-409-4519 | sara.lambeth@tdk.com |