Contribute to the World through Technology

Contribute to resolving social issues through development and provision of new products in three priority markets

Creating new value to address social needs

For the TDK Group, which subscribes to the corporate motto of

“Contribute to culture and industry through creativity,” utilizing

technical expertise to enrich people’s lives is an unwavering corporate

mission. Under the guidance of the government’s 5th Science

and Technology Basic Plan, Japan is currently working to emerge

as a “Super Smart Society*.” Revolutionary social changes driven

by innovation are christened “Society 5.0*”—a domain we are positioned

to contribute to through the various technologies of the TDK

Group. The “Society 5.0” vision speaks not only to Japan, but also

to advancing global culture and industry. TDK is now grappling

with the question of how best to approach this vital new challenge.

Closer communications with customers, while raising the synergy

between the Technology and Intellectual Property HQ and other

TDK business groups, holds the key to creating new value. This

also harbors potential for expanding new products and services

beyond the current three priority markets of Automotive, ICT, and

Industrial and Energy. The cornerstone of such progress promises

to be magnetic technology—the DNA embodying the TDK Group.

Recent years have witnessed steady expansion in fields in which

TDK products and services are being put to use. Examples include

magnetic sensors applying HDD head technology, automotive

electronic components for EVs, HEVs, and other eco-friendly

cars, and sensors for use in the medical and health care field. Fully

harnessing strengths that only TDK can deliver, our goal is to help

pave the way to making “Society 5.0” a reality.

Developing highly social-sensitive engineers

People must shoulder the technologies that support society, pointing to an equally critical need for individual engineers to raise their awareness and sensitivity toward the world around them. Demanded today is the perspective of identifying special social issues, systems to help resolve those challenges, and the products to get the job done. As CTO, I believe that my foremost role is to promote the milestone mindset shift from Monozukuri to Kotozukuri. From the standpoint of training young people, the Technology and Intellectual Property HQ dispatches engineers to the various business groups in their third to fifth years with TDK. There, they are expected to actively engage in new product launches, etc., think on their own and steadily accrue opportunities to expand experience. Moving forward, one of the key challenges is to establish an effective R&D system on the foundation of worldwide personnel exchange. Likewise, in view of the growing number of engineers also raising families, a scheme to support a positive balance between work and child-raising is another key to success. Taking this to heart, my mission is to make TDK a work-friendly company for our vastly diversified employees, fully utilizing people potential to raise the essential technologies at TDK to ever-greater heights.

*Super Smart Society

Addressing a vast range of needs with the supply of the necessary goods and

services to customers when they need them and in the proper quantities, in support

of an energetic and comfortable society where everyone enjoys access to top-caliber

services.

*Society 5.0

Creation of a new social mode, following in the footsteps of the hunting, agricultural,

industrial, and information societies before it, championed by technological innovation.

TDK’s Three Priority Markets

AUTOMOTIVE

Mr. Michael Besemann (Left)

Project Leader R&D

TDK-Micronas GmbH

Mr. Jens Schubert (Right)

Product Marketing Manager Magnetic Sensors

TDK-Micronas GmbH

Contribute to environmental burdens reduction with new HAC 37xy sensor

This new direct angle hall sensor provides high performance in strength evaluation of horizontal and vertical magnetic field components and enables angle measurements of up to 360° or linear measurements of up to 40 mm. It contributes to reduction of fuel consumption and CO2/NOx emissions, and also provides cost reduction. This product is the accomplishment of collective effort of several experts.

ICT

Head of R&D MEMS Microphones Business Division,

TDK Sensor Systems Business Company, Munich

EPCOS AG

Bringing professional audio quality to smartphones

Smartphones and action cams already offer great video. My team’s design goal was to create a miniature microphone with the best audio. Thanks to our patented MEMS* design, the T4071 MEMS microphone sets the benchmark for nearly noise-free signal quality and lowest distortion – a true competitive advantage for TDK. As a result, users of these compact devices can now make videos with professional audio, even with really high sound levels.

* Micro electro mechanical systems (MEMS) are extremely small highly-functional devices and systems. Their miniaturized integrated mechanical components and electronic circuit are manufactured using microfabrication techniques similar to those used for ICs.

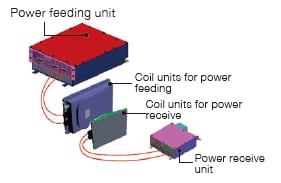

Industrial and Energy

Development Office II,

Energy Unit Development Division

Technology and Intellectual Property HQ

TDK Corporation

Further enhancing wireless power transfer technology, bringing innovation to the industrial equipment market

A revolutionary product engineered for wireless and automatic charging of batteries primarily onboard industrial equipment. This eliminates the need to insert and extract plugs and replace batteries. The results include 24-hour operation based on the automatic charging system, reduced maintenance costs, lower electric shock risk, and other benefits. For the emerging industrial equipment market, this product holds outstanding potential for use in automatic guided vehicles, industrial robots and other applications. Looking ahead, our goal is to raise overall system efficiency based on keen attention to safety and the environment.