TDK Develops Compact, High-Capacitance MLCC for 100V Applications

Information contained in the news releases are current as of the date of the press announcement, but may be subject to change without prior notice.

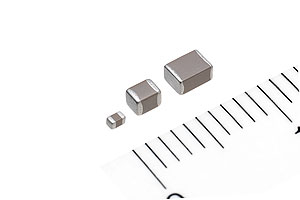

Industry's Highest Level of Capacitance for 100V Rated Capacitors; Up to 50% Smaller

June 17, 2009

TDK Corporation announced today that it has developed a multilayer ceramic chip capacitor with a rated voltage of 100V for mid-voltage applications. Mass production and sales is scheduled to begin in July. The new product uses ceramic dielectric thin-layer technologies and multilayering technologies, areas in which TDK excels, to improve capacitance to the industry's highest levels in the mid-voltage range.

In recent years, the fundamental driving performance of automobiles has been improved even as comfort and safety functions have become more advanced and proliferated, supported by substantial increases in the use of electronic equipment. In addition, next-generation eco-friendly cars that can contribute to reducing environmental impact through better fuel efficiency and lower carbon dioxide emissions have attracted considerable attention. Amidst these developments, the number of electric devices installed in limited space is increasing, and market demand for on-board electronic components that can contribute to the miniaturization of electrical devices and save space is rising.

TDK is responding to these market needs by using its strengths in materials technologies and multilayering technologies to reduce the gaps between ceramic dielectrics layers by approximately 40% compared to earlier products. In addition, sintering conditions were optimized to maintain the reliability needed for automobile on-board multilayer ceramic chip capacitors while making components smaller and increasing capacitances.

As a result, the new products have the same capacitance of earlier TDK components but are approximately 50% smaller, while a component that is the same size has approximately double the capacitance. They feature X7S temperature characteristics (operating temperature range: -55°C to 125°C; change in capacitance: ±22%), making them ideal for use in engine compartments as well as the switching power supply smoothing circuits1 needed for industrial equipments.

-

Glossary

- 1) Smoothing circuit : A type of electronic circuit that uses capacitors and other components to control pulsating current included in rectified current by releasing stored charge, producing smoother current.

-

Main Features

-

- Gaps between ceramic dielectric layers are reduced by 40% compared to earlier products to increase capacitance, reduce size, and raise capacity.

- X7S temperature characteristics (operating temperature range: -55°C to 125°C; change in capacitance: ±22%)

-

Main Applications

-

- Input/output smoothing in automobile engine compartments (battery lines, etc.)

- Industrial equipment switching power supply smoothing

-

Main Characteristics

-

Configuration Thickness(mm) Rated Voltage (V) Capacitance (µF) Temperature Characteristics C1005(0402) 0.55 max 100 0.01 X7S C1608(0603) 0.90 max 100 0.1 X7S C2012(0805) 1.45 max 100 1.0 X7S C3216(1206) 1.80 max 100 2.2 X7S C3225(1210) 2.20 max 100 3.3 X7S C4532(1812) 2.50 max 100 4.7 X7S C5750(2220) 2.80 max 100 10 X7S -

Production and Sales Plan

-

- Production location: Akita region

- Production capacity: 30 million units/month (planned)

- Start of production: July 2009

For further information, contact the Corporate Communications Dept.

Tel.: 81-3-6778-1055

E-mail: TDK.PR@tdk.com