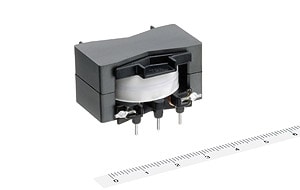

TDK Develops and Starts Mass Production of New Series of Low-Profile, 20 mm - 25 mm PFC1 Choke Transformers

for FPDs

Information contained in the news releases are current as of the date of the press announcement, but may be subject to change without prior notice.

The industry's first* series of products designed especially for flat-panel displays.

New core configuration reduces volume 30% and weight 20% compared to earlier products.

March 10, 2008

TDK Corporation announced today that it has developed and begun the full-scale mass production of new series of low-profile PFC choke transformers just 20 mm to 25 mm high designed especially for flat-panel displays. These new transformers are intended for use in circuits that improve the power factors of flat-panel display power supplies. These products use PC47, a ferrite material developed by TDK, for the wound core of the coil and adopt a new configuration that allows the winding wire cross-section to be increased while maintaining a low-profile design. As a result, the performance is the same as the current SRW4025EC choke transformers, but the volume is 30% smaller and the weight is 20% lower.

The lineup of new choke transformers consists of the industry's first series ranging from 75 W to 300 W. A total of 12 different products in four series enable users to choose the optimal transformer according to the specific application.

Information home appliances such as flat-panel displays are being made thinner, smaller, and lighter even as they incorporate numerous advanced functions, and use of switching power supplies is becoming common. Many of these switching power supplies are capacitor input types with capacitors after the rectifier circuit that converts alternating current to direct current, but charging and discharging the capacitors reduces the power factor. Power factor improvement circuits can reduce this effect, and in recent years the use of such circuits has increased considerably.

To respond to these needs, the new choke transformers were designed specifically for use in power factor improvement circuits. The core is made of a high saturation flux density2 ferrite material developed by TDK that contributes to higher performance and miniaturization.

- * As of March 2008, according to TDK investigations.

-

Glossary

-

- PFC: Power factor correction.

Refers to an increase in power efficiency. The power factor is the ratio of the real power to the apparent power. - Saturation flux density.

The flux density at which a core first becomes saturated when a magnetic field is applied. The larger the saturation flux density, the smaller the core cross-section and number of windings can be and the greater the voltage that can be controlled.

- PFC: Power factor correction.

-

Main Features

-

- Low-profile configuration-height reduced from the 27 mm of earlier products (SRW4025EC types) to 20 mm.

- Use of PC47, a high saturation flux density material developed by TDK that makes high-current use possible, in the core and a newly-designed core configuration make possible a 30% reduction in volume and a 20% reduction in weight.

- Lineup consists of 12 products ranging from 75 W to 300 W in four series-the industry's first series of standard products. Coils are automatically wound for enhanced stability in quality and supply.

-

Main Applications

- Improving power supply efficiency in flat-panel displays.

-

Main Characteristics

-

Product Configuration

(mm)Input voltage

(V)Output

power

(W)Driving

frequency

(kHz)Inductance PFC3318QM-601K03B-01 28×35×20 85~264 75 50 600μH PFC3318QM-601K03E-01 28×35×20 85~264 75 50 600μH PFC3318QM-451K04B-01 28×35×20 85~264 100 0 450μH PFC3519QM-451K04E-01 30×37×20 85~264 100 50 450μH PFC3519QM-301K06B-01 30×37×20 85~264 150 50 300μH PFC3819QM-301K06E-01 33.5×40×20 85~264 150 50 300μH PFC3519QM-231K07B-01 30×37×20 85~264 200 50 230μH PFC3819QM-231K07D-01 33.5×40×20 85~264 200 50 230μH PFC3819QM-181K09B-01 33.5×40×20 85~264 250 50 180μH PFC4124QM-181K09D-01 38×43×25 85~26 250 50 180μH PFC3819QM-151K11B-01 33.5×40×20 85~264 300 50 150μH PFC4124QM-151K11D-01 38×43×25 85~264 300 50 150μH -

Production and Sales Plan

-

- Production location: China

- Production capacity: 1 million units/month

- Start of production: January 2008

For further information, contact the Corporate Communications Dept.

Tel.: 81-3-6778-1055

E-mail: TDK.PR@tdk.com