TDK Develops and Begins Mass Production of Industry's First* Multilayer Capacitor that Allows ESR1 Values to be Set Using New Internal Structure

Information contained in the news releases are current as of the date of the press announcement, but may be subject to change without prior notice.

New Capacitor Stabilizes ESR Values, Simplifies Circuit Design, and Contributes to Reduction of the Number of Components

February 20, 2008

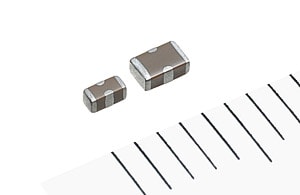

TDK Corporation announced today that it has developed the industry's first multilayer ceramic chip capacitor with a new internal structure that allows ESR values to be set to any value within a specified range, stabilizes ESR values, and can control circuit impedance (alternating current resistance). Mass production of the capacitor, available in 1608 and 2012 configurations, began in February.

In conjunction with the smaller size and increasingly advanced functions of electronic devices such as PCs and mobile information terminals, manufacturers are making strong demands for reduced mounting areas and miniaturization of components. As a result, power supply circuits on boards with ever higher mounting densities must combine multiple capacitors of different types, which means that impedances must be adjusted over broad frequency ranges. The effects of the minute electrical resistance elements present in the capacitors themselves can cause interference among multiple capacitors depending on the frequency, which can lower noise suppression effects. Generally, it is necessary to use even more components to control these effects.

To respond to these demands, TDK used its strengths in materials technology and multilayering technology to develop a capacitor with a new internal structure that allows ESR values to be set while maintaining the same capacitance as earlier products. Because the ESR values of capacitors located in the vicinity of the CPU can be set, there are smaller changes in impedance between the power supply and the CPU over a broad range of frequencies as well as voltage variation limiting effects. Limiting the variation in voltage stabilizes the current signal and eliminates effects on other circuits. In addition, the new capacitor will likely contribute to a reduction in the number of components needed.

The new capacitors are suitable for use in applications that require high power supply quality such as communications base stations and high-end PCs, and will contribute to reductions in the number of components, space saving, and smaller products. The mounting method is the same as that for two-terminal products, making switching from existing components easy.

* As of February 2008, according to TDK investigations.

-

Glossary

-

- ESR: equivalent series resistance.

The actual resistance value when a component is inserted in a circuit.

- ESR: equivalent series resistance.

-

Main Features

-

- Although the sizes are the same as earlier products of the same type, resistance has been improved to 1200 mΩ for the 1608 product and 500 mΩ for the 2012 product and the ESR values can be set to any value within a specified range.

- By adding resistance components, the variation in impedance frequency is lower than earlier products, which will contribute to reducing the number of components needed compared to earlier products.

-

Main Applications

- Power supply decoupling2 and DC/DC converter input/output smoothing.

2. Decoupling: The process of preventing the effects of noise from other circuits. -

Main Characteristics

-

Format 1.6 mm × 0.8 mm × 0.8 mm 2.0 mm × 1.25 mm × 0.85 mm Capacitance 1 µF max. 10 µF max. Temperature characteristics B characteristics (X5R) B characteristics (X5R) Rated voltage 4 V - 6.3 V 4 V - 6.3 V ESR settable range 10 mΩ - 1200 mΩ 10 mΩ - 500 mΩ -

Production and Sales Plan

-

- Sample prices 1608 component: 20 yen

2012 component: 60 yen - Production location : Akita region

- Production capacity : 5 million units/month

- Start of production : February 2008

- Sample prices 1608 component: 20 yen

For further information, contact the Corporate Communications Dept.

Tel.: 81-3-6778-1055

E-mail: TDK.PR@tdk.com