Multilayer ceramic chip capacitors: Portfolio of automotive-grade C0G mid-voltage MLCCs expanded

- CGA series includes world’s first IEC 5750 type with a rated capacitance of 100 nF and rated voltage of 630 V

- Qualified to AEC-Q200.

May. 16, 2013

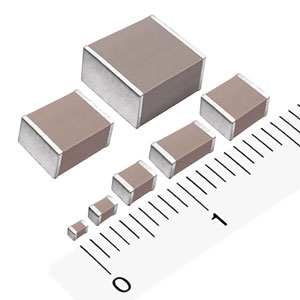

TDK Corporation has expanded its leading portfolio of automotive-grade MLCCs with new mid-voltage types featuring C0G temperature characteristics and rated voltages from 100 V to 630 V. The new components in the CGA series offer capacitance values that are very high for C0G components. In particular, the IEC 5750 (EIA 2220) MLCC with dimensions of 5.7 mm x 5.0 mm has a capacitance of 100 nF and is rated for 630 V, which is the world’s highest voltage rating for a capacitor of this size and capacitance.*

The new high reliability components are designed for operating temperatures of up to 125 °C, and are qualified to AEC-Q200. The expanded series offers a wide lineup of sizes from 1005 to 5750 (EIA 0402 to 2220) and combines the high reliability and high capacitance required for automotive applications. The addition of new types rated for 450 V (2012 size and above) and 5750 size types, has increased the range of C0G mid-voltage MLCCs substantially, providing increased flexibility for various market requirements. Special customer requirements (such as temperature ratings of up to 150 °C) can be met upon request. Mass production started in April 2013.

Thanks to their C0G temperature characteristics (-55°C to +125°C, temperature coefficient of 0 ±30 ppm/°C max.), the new components in the CGA series are suitable not only for engine control units (ECUs) in cars, but also for other applications where high reliability is required. Typical examples include filtering, resonance, oscillation, snubber, and time constant circuits in power supplies for consumer and industrial products.

MLCCs are among the key electronic components driving progress in automotive electronics and TDK is the leader in the area of MLCCs for automotive applications. TDK has harnessed its mastery of a range of sophisticated technologies, including dielectric powder manufacturing, high-dispersion processing, as well as thin- and multilayer technology for dielectric ceramics.

- * As of May 2013, according to TDK data.

Main applications

-

- Engine control units (ECU) and remote keyless entry systems (RKE) for automobiles

- EV/HEV inverters and DC-DC converters

- Resonance circuits for wireless power transmission

- Power supplies for general consumer products

- Various types of sensors, etc.

Main features and benefits

-

- C0G temperature characteristics (-55°C to +125°C, temperature coefficient of 0 ±30 ppm/°C max.) eliminate temperature- or time-dependent fluctuations of DC bias and capacitance, ensuring that circuits consistently achieve the output that they are designed for.

- Expanded CGA series includes products rated for voltages from 100 V to 630 V

- Qualified to AEC-Q200

Key data

-

Dimensions (l x w)

[mm]Rated voltage

[V]Rated capacitance

[nF]Temperature characteristics 1.0 x 0.5 100 0.1 to 0.47 C0G 1.6 x 0.8 100 to 250 0.82 to 3.3 C0G 2.0 x 1.25 100 to 450 0.1 to 10 C0G 3.2 x 1.6 100 to 630 6.8 to 33 C0G 3.2 x 2.5 100 to 630 22 to 68 C0G 4.5 x 3.2 100 to 630 33 to 100 C0G 5.7 x 5.0 100 to 630 68 to 150 C0G

About TDK Corporation

TDK Corporation is a leading electronics company based in Tokyo, Japan. It was established in 1935 to commercialize ferrite, a key material in electronic and magnetic products. TDK's portfolio includes electronic components, modules and systems which are marketed under the product brands TDK and EPCOS, power supplies, magnetic application products as well as energy devices, flash memory application devices, and others. TDK focuses on demanding markets in the areas of information and communication technology and consumer, automotive and industrial electronics. The company has a network of design and manufacturing locations and sales offices in Asia, Europe, and in North and South America. In fiscal 2013, TDK posted total sales of USD 9.1 billion and employed about 80,000 people worldwide.

About TDK-EPC Corporation

TDK-EPC Corporation, a TDK group company, is the manufacturer of TDK’s electronic components, modules and systems and is headquartered in Tokyo, Japan. TDK-EPC was founded on October 1, 2009 from the combination of the electronic components business of TDK and the EPCOS Group. The product portfolio includes ceramic, aluminum electrolytic and film capacitors, ferrites, inductors, high-frequency components such as surface acoustic wave (SAW) filter products and modules, piezo and protection components, and sensors.

Downloads

- Product with background (jpg: 179.9 KB; 350dpi)

- Product without background (jpg: 173.3 KB; 350dpi)

- Press release (pdf: 39.3 KB; )

- Press release (rtf: 175.5 KB; )

Contacts for regional media

| Region | Contact | Phone | ||

|---|---|---|---|---|

| Japan | Ms. Mari KONISHI | TDK Corporation Tokyo/ Japan |

+813 6778-1055 | TDK.PR@tdk.com |

| ASEAN | Ms. Jiang MAN Mr. Shota KANZAKI |

TDK Singapore (Pte) Ltd. Singapore |

+65 6273 5022 | TDK.ASEAN-inquiry@tdk.com |

| Greater China | Ms. Clover XU | TDK China Co., Ltd. Shanghai/ China |

+86 21 61962307 | TDK.PR-CN@tdk.com |

| Europe | Mr. Frank TRAMPNAU | TDK Electronics Europe GmbH Duesseldorf/ Germany |

+49 211 9077 127 | trampnau@eu.tdk.com |

| America | Mr. Sara M. LAMBETH | TDK Corporation of America Richardson, TX, USA |

+1-972-409-4519 | sara.lambeth@tdk.com |