Electronics ABC

Capacitors — Part 5 "Film Capacitors [2]"

Key Takeaways

1. Film capacitors use plastic dielectric films with either metallized layers or foil electrodes, providing stable electrical characteristics and low losses across AC applications.

2. Dielectric materials define behavior: PET offers strong temperature stability and wide usability, while PP delivers very low loss, high insulation resistance, and excellent high-frequency performance.

3. Thinner dielectric films increase capacitance density but lower breakdown voltage, requiring a careful balance between miniaturization and long-term reliability.

4. Capacitance changes with temperature and frequency vary by material: PET shows moderate drift, while PP maintains superior stability at higher frequencies.

5. Metallized film structures enable a self-healing effect, where localized breakdown sites are isolated automatically, extending component lifetime.

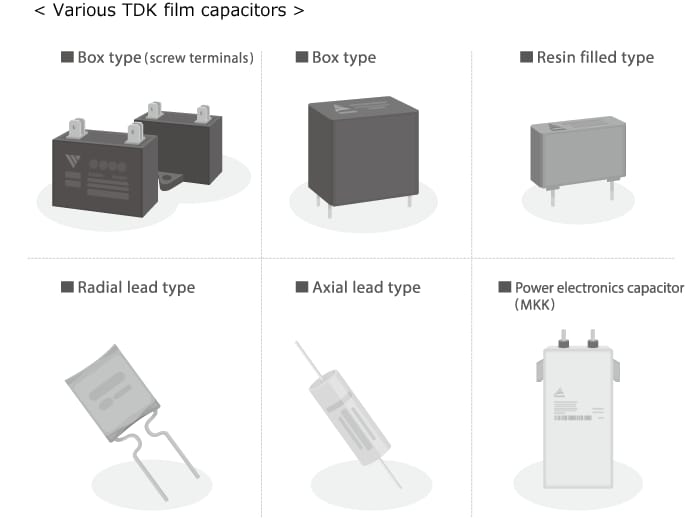

6. TDK film capacitor families include MKP, MKT, pulse capacitors, DC-link types and encapsulated variants, supporting power electronics, industrial equipment, and grid-level applications.

Main Characteristics of Film Capacitors

●Rated voltage

This specifies the maximum voltage that can be applied to the capacitor on a constant basis. Rated voltage can be given for DC (direct current) and AC (alternating current). For film capacitors, both the DC and AC rated voltage is usually in the range from several tens to several hundred volts. High-voltage types for electric power systems have an AC voltage rating on the order of several thousand volts and higher. The AC rating is the voltage for capacitors assumed to be used in circuits handling alternating current only. When used for AC, a corona discharge will occur if the applied voltage exceeds a certain level. Continuous corona discharge may lead to insulation breakdown. Because the rated voltage has a tendency to drop as temperature rises, capacitors must be selected with a sufficient margin.

●Self-heating

High frequency currents or ripple currents will cause self-heating in film capacitors. The temperature rise normally remains within about 5 to 10°C, but care must be taken that the ambient temperature plus self-heating temperature does not exceed the usage range of the capacitor.

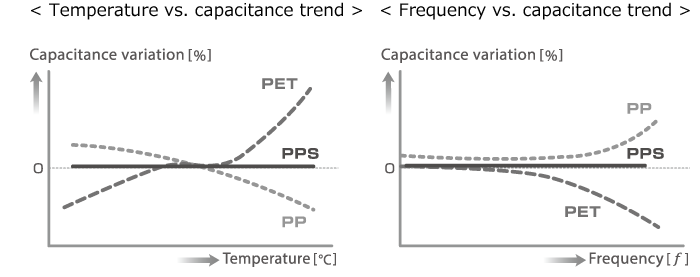

●Thermal characteristics and frequency characteristics of capacitance

The capacitance of a film capacitor is influenced by temperature. The ratio of change will differ, depending on the type of plastic film used as dielectric. With PPS, there will be almost no change in capacity. With PET, the change is characterized by a positive temperature coefficient and with PP by a negative temperature coefficient. There are also compound capacitors that use a combination of materials with opposed thermal coefficients to stabilize capacitance. The capacitance will also vary according to the frequency, as shown in the graph below. A special feature of PPS is the fact that both its thermal characteristics and frequency characteristics are excellent.

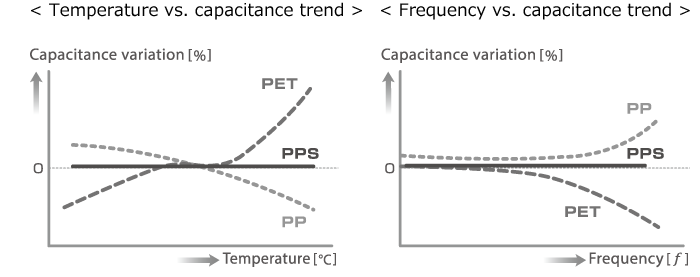

●Thermal characteristics and frequency characteristics of tanδ (dielectric tangent)

The smaller the value of tanδ (dielectric tangent), the lower the thermal loss, making for a better film capacitor. However, tanδ tends to increase towards higher frequencies. This increase is least pronounced in PP capacitors, making them suitable for high-current applications. Temperature dependent change of tanδ is also almost absent in PP capacitors.

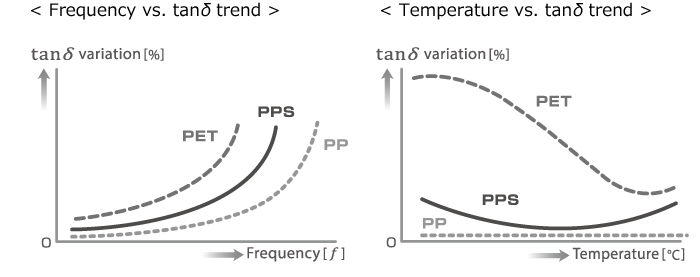

●Self-healing and protection functions of vapor deposition electrode

A major feature of vapor deposition electrode film capacitors is the self-healing property of the vapor deposition electrodes. In case of an electrically weak point in the film, or when excessively high voltage is applied, causing insulation breakdown, the vapor deposited film momentarily is oxidized which restores the insulated state.

For further improved reliability, most capacitors of this type also incorporate a protection function in the vapor deposited film. Instead of using uniform deposition over the entire area of the film, the film is divided into a pattern of multiple tile shaped areas which are connected by thin fuse sections. When an insulation breakdown situation exceeding the self-healing capacity occurs, the fuse section melts to avert the insulation breakdown. Various different types of vapor deposition patterns are used to achieve this property.

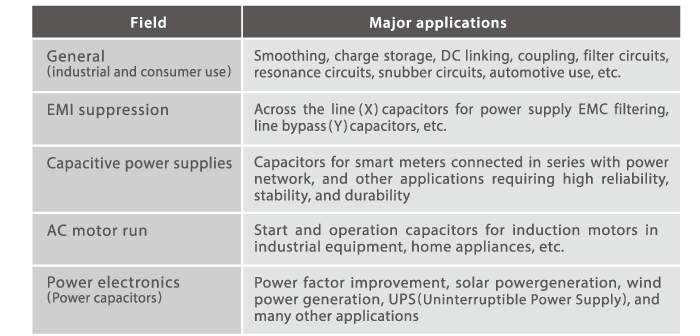

TDK film capacitor types and major applications

Conclusion

Film capacitors remain a core technology in modern power and signal-handling circuits thanks to their combination of stability, low losses, and predictable behavior under varying electrical and thermal stresses. The choice of dielectric—most commonly PET or PP—directly defines performance, from temperature drift to high-frequency response. Metallized constructions further enhance durability through self-healing, a key advantage in demanding power environments. These capacitors support everything from consumer power supplies to industrial drives, renewable-energy inverters, and automotive electronics, making them a versatile and reliable solution wherever stable capacitance and long operational life are essential.

FAQ

Q: Why are film capacitors considered low-loss components?

A: Their dielectric materials exhibit very low dissipation factors, enabling efficient operation with minimal heat generation even at high AC currents.

Q: What is the difference between metallized film and foil electrodes?

A: Metallized films use a thin vapor-deposited electrode that supports self-healing and compact designs, while foil electrodes handle higher pulse currents and are used where maximum robustness is required.

Q: Which dielectric materials are typically used?

A: PET and PP are the most common. PET provides good stability and compactness; PP offers excellent high-frequency behavior and exceptionally low losses.

Q: Why does capacitance change with frequency?

A: At higher frequencies, dielectric losses and parasitic inductive effects increase, reducing effective capacitance.

Q: What is the self-healing effect?

A: In metallized film capacitors, a local dielectric breakdown vaporizes the surrounding electrode material, isolating the defect and allowing continued operation.

Q: Where are TDK's film capacitors most commonly used?

A: In DC-link circuits, EMI/RFI filters, inverter stages, pulse circuits, industrial power systems, and automotive power electronics.

TDK is a comprehensive electronic components manufacturer leading the world in magnetic technology