Electronics ABC

Capacitors, Part 4 "Film Capacitors [1]"

Key Takeaways

1. Capacitor Type: Film capacitors use plastic films; evolved from paper caps and are prized for their excellent insulation and reliability.

2. Electrode Styles: Two electrode styles exist: foil plates versus metallized film; metallized types allow for significantly smaller parts.

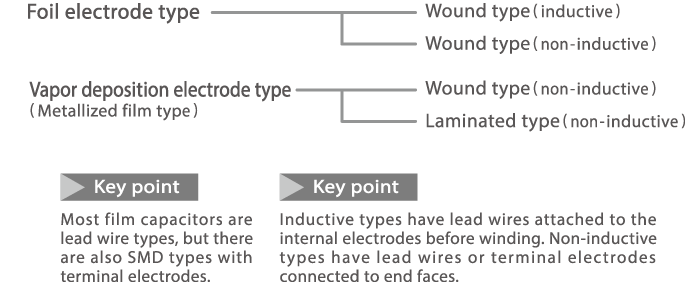

3. Constructions & Termination: Construction can be wound or laminated; terminations can be inductive or non-inductive for different high-frequency (HF) behavior.

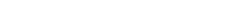

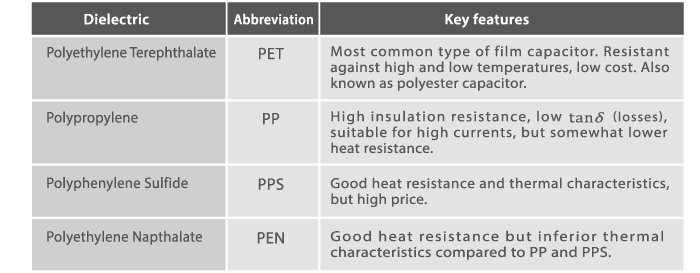

4. Dielectric Selection: The choice of dielectric (e.g., PET, PP) determines the capacitor's stability, loss characteristics, and voltage range; it must be picked per use conditions.

5. Common Materials: PET ("Mylar") is common; polystyrene has largely been displaced by polypropylene (PP) in most modern designs.

6. High-Frequency Response: Non-inductive end-face connections effectively cut stray inductance, which significantly improves the capacitor's high-frequency response.

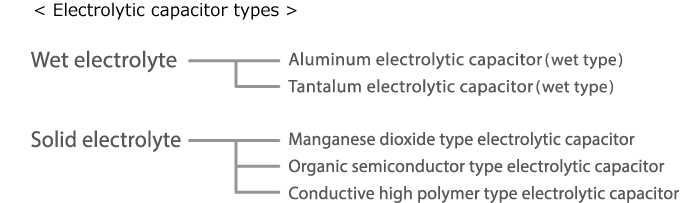

Film capacitor types

As their name suggests, film capacitors employ a plastic film as dielectric. The technical ancestor of this type of capacitor is the paper capacitor invented in the second half of the 19th century. It consisted of paper impregnated with oil or paraffin, sandwiched between sheets of aluminum foil and rolled into a round shape. A capacitor where the metal foil is replaced by a layer of metal directly created on the paper by means of vapor deposition is called an MP (metallized paper) capacitor. Based on this technique, film capacitors were developed in the 1930s. Compared to multilayer ceramic chip capacitors, it is difficult to make film capacitors small, but they offer high insulation resistance and high reliability. Film capacitors are found for example in electric home appliances, electronic circuits in cars, industrial equipment, and power electronics devices.

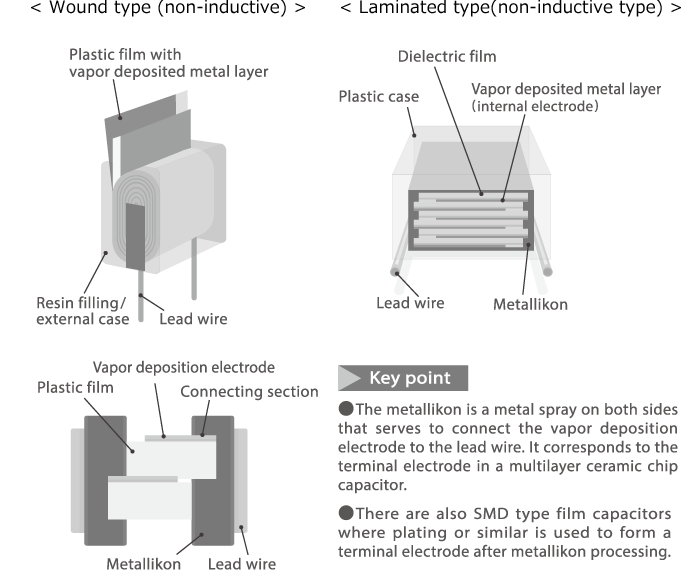

Depending on how the internal electrode is formed, film capacitors are divided into two main categories, namely foil electrode types and vapor deposition electrode (metallized film) types. Subcategories according to construction include wound types, laminated types, inductive and non-inductive types, etc.

Major dielectrics used for film capacitors and their characteristics

The plastic films listed below are used as dielectrics of film capacitors. Capacitors using PET as dielectric are also called mylar capacitors, after the brand name of a PET film made by DuPont. So-called styrol capacitors are film capacitors using polystyrene (styrol resin) as a dielectric. This type has been largely replaced by PP types and is no longer manufactured in significant quantities today.

Performance comparison of film capacitors by dielectric

The performance of film capacitors differs, depending on the type of dielectric. It is therefore necessary to select the proper type according to the usage conditions.

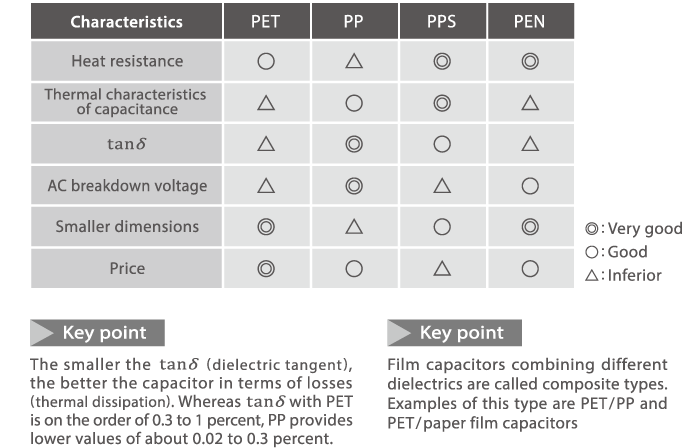

Construction of film capacitors

●Foil electrode type film capacitors

Wound type film capacitors with internal electrodes are made of metal foil (aluminum, tin, copper, etc.) sandwiched between plastic film layers and rolled up. They come in inductive and non-inductive versions. Inductive types have lead wires attached to the internal electrodes before winding, while non-inductive types have lead wires or terminal electrodes connected to end faces. Compared to inductive types, non-inductive film capacitors have a lower inductance component and exhibit better high frequency characteristics.

●Vapor deposition electrode type (metallized film type)

Instead of using foil as electrode, this type of film capacitor uses a layer of metal (aluminum, zinc, etc.) deposited on the plastic film itself to form an internal electrode. Because the deposited film is very thin, the capacitor can be made smaller than the foil electrode type.

Vapor deposition type capacitors are of the non-inductive type where the electrode is connected to an end face. In terms of manufacturing method there are wound types and laminated types.

Manufacturing process of film capacitors

Conclusion

Film capacitors trade compactness for insulation and reliability. Your choice hinges on three levers: dielectric (PET, PP…), electrode method (foil vs metallized), and geometry/termination (wound/laminated, inductive/non-inductive). For high-frequency work, non-inductive builds help; for smaller size, metallized film is the go-to.

FAQ

What defines a film capacitor?

A plastic film dielectric between electrodes; it offers high insulation resistance and solid reliability.

Foil vs metallized film—what’s the difference?

Foil capacitors use separate metal foils; metallized types deposit a thin metal layer on the film, reducing size.

What do “wound” and “laminated” mean?

Wound parts are rolled layers; laminated parts stack layers. Both can be built as metallized or foil types.

What is “non-inductive” construction here?

Leads or terminals connect to the end faces, minimizing series inductance for better high-frequency traits.

Why are PET capacitors called “mylar”?

“Mylar” is DuPont’s PET film brand; the name stuck as a shorthand for PET-dielectric film capacitors.

Are polystyrene film capacitors still made?

Largely no; they have mostly been replaced by polypropylene types.

Where are film capacitors used?

In home appliances, automotive electronics, industrial equipment, and power electronics.

TDK is a comprehensive electronic components manufacturer leading the world in magnetic technology