The World of Power Electronics

Part 2: How Do Switching Power Supplies Work? A Historical Overview of Revolutionary Power Supply Technologies

Electronic devices equipped with ICs and microcomputers require stabilized direct current with little voltage fluctuation. There are two types of stabilized power supplies: linear and switching. Switching power supplies broke through the limitations of conventional linear power supplies, achieving groundbreaking miniaturization, weight reduction, and high efficiency. Switching power supplies embody the key technologies of power solutions.

Key Takeaways

1. Switching power supplies revolutionized electronics by replacing bulky, heat-heavy linear power supplies with compact, lightweight, and high-efficiency designs.

2. In a linear power supply, AC is transformed to a lower voltage first, then rectified and smoothed into DC. Heat dissipation through variable resistors or regulator ICs limits efficiency.

3. Switching power supplies invert the sequence: they rectify AC to DC first, then rapidly switch the DC into high-frequency pulses before voltage conversion—achieving higher efficiency and reduced size.

4. The PWM (Pulse Width Modulation) control method regulates voltage by adjusting pulse width, maintaining stable output with minimal energy loss.

5. Because switching frequencies reach tens or hundreds of kilohertz, traditional iron-core transformers are replaced by ferrite-core transformers, which minimize losses at high frequencies.

6. Linear power supplies remain favored for precision instruments and audio gear due to low noise, while switching designs dominate mobile chargers, PCs, and appliances for their efficiency.

7. A 1% improvement in power supply efficiency can yield significant global energy savings, making high-performance ferrite materials a key enabler of sustainable power electronics.

8. TDK’s ferrite and noise-suppression technologies address the dual challenges of switching noise and electromagnetic interference (EMI), supporting next-generation compact, eco-efficient devices.

Why AC adapters based on the linear method are heavy and bulky

An AC adapter, which converts commercial AC to DC, is a good example for learning the basic technology behind power supplies. AC adapters were usually heavy, bulky objects in the past, but they are much lighter and smaller today, exemplified by a mobile phone charger. This is because the switching method has become mainstream since the early 2000s, replacing the conventional linear method.

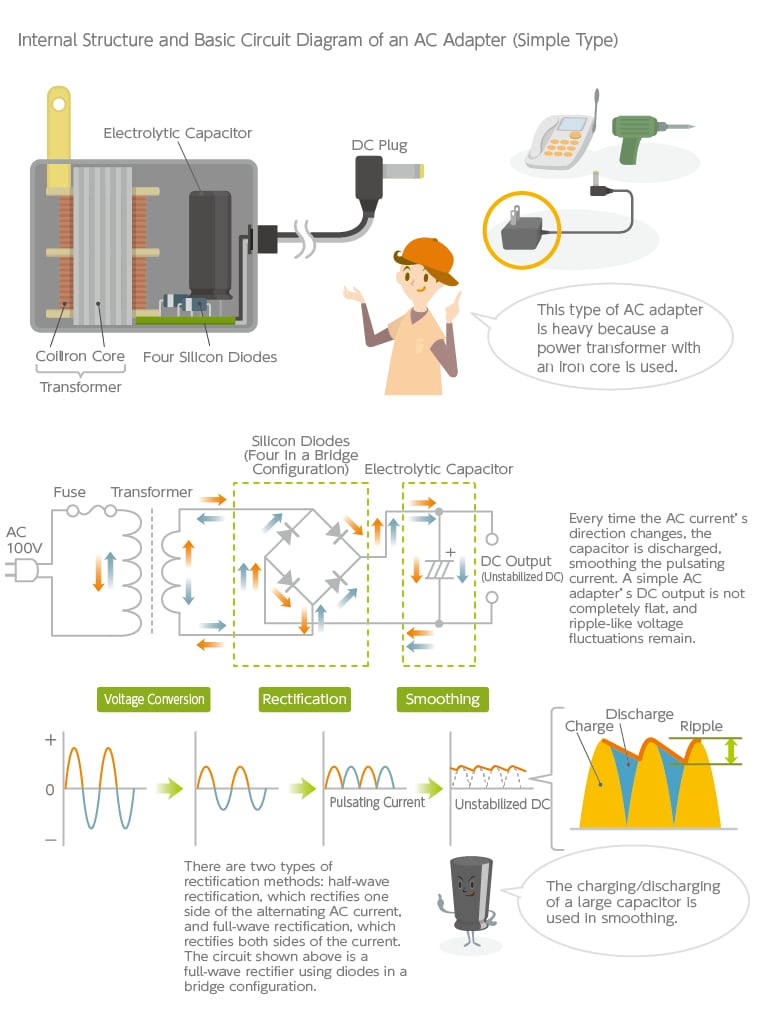

The differences between the linear and switching methods are discussed below, but first, let’s look at a simple, conventional AC adapter—a linear power supply without a stabilizing circuit. This type of AC adapter features simple circuitry and low cost, and is used in land-line cordless phones, desktop computer speakers, power tools, etc. Though hard to tell from its external appearance, most of its weight and volume are attributable to the power transformer inside, consisting of a coil wound around a solid iron core. The power transformer converts the 100V AC voltage to a lower AC voltage. Subsequently, the AC current is rectified using diodes—elements that pass current flowing in one direction but block it in the opposite direction.

Even after rectification, the current is still pulsating and far from a clean DC current, so it is further flattened by a smoothing circuit based on a capacitor. A capacitor stores electrical charge, which is its fundamental functions. The rectifying circuit shown in the figure below is an example that uses diodes in a bridge configuration (a full-wave rectification method). Even when the AC current reverses its direction, the current flowing to the capacitor is always in the same direction, charging the capacitor. In pulsating currents, the current and voltage both fluctuate widely in a cyclical manner, and the capacitor discharges its stored energy accordingly to suppress these fluctuations. High-capacity capacitors are required in smoothing circuits; thus, aluminum electrolytic capacitors are typically used. Additionally, a choke is sometimes placed in series with the capacitor, utilizing the coil’s ability to hinder changes to current, thereby further contributing to smoothing.

Stabilized DC power supplies are critical to digital electronic devices

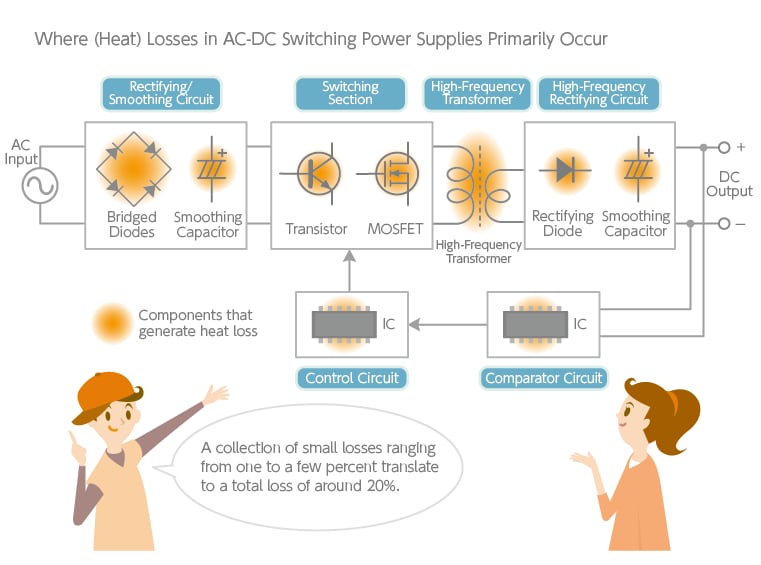

The function of an AC-DC power supply, such as an AC adapter, is to obtain DC from a commercial AC source. However, the quality of DC varies greatly. In a simple AC adapter, even after the pulsating current is smoothed out, ripples still remain in the waveform. Voltage fluctuations of the commercial AC input can also destabilize the DC output’s voltage. These imperfections may not be a problem for tasks like battery charging, but can cause low-voltage ICs to fail, necessitating a more even and stable DC current. A power supply equipped with a stabilizing circuit (a regulator) for this purpose is called a stabilized power supply.

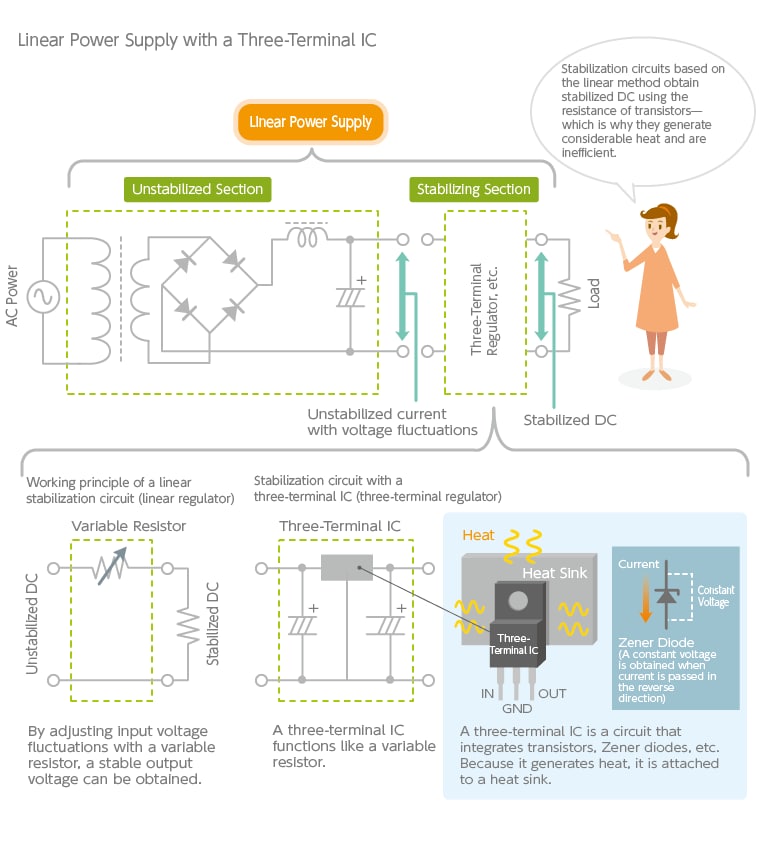

Stabilized power supplies are broadly classified into linear and switching power supplies based on the method used. Linear power supplies have been in use since the days of vacuum tubes. The principle is quite simple: the output voltage is adjusted by incorporating a variable resistor into the circuit. Zener diodes and three-terminal ICs (also known as three-terminal regulators) are examples of components that function as variable resistors.

Zener diodes are also called constant voltage diodes. Regular diodes are used as rectifying elements by allowing current flow in one direction but not in the opposite direction. However, if a voltage is applied in the reverse direction and is continually increased, a threshold will eventually be reached where the diode abruptly begins to pass current. Zener diodes make use of this phenomenon to allow current to flow only above a certain voltage; it can thereby be used to maintain a constant output voltage.

A three-terminal IC is a component that detects the difference between the voltage set by the Zener diode (known as the reference voltage) and the actual output voltage, and stabilizes the voltage by amplifying and correcting it using a transistor. It’s called a “three-terminal IC” because the entire circuit is built on a single chip and features three terminals: IN, OUT, and GND (ground). They have been widely used in electronic devices because of their small size and ease of use. They do generate large amounts of heat, requiring heat sinks for heat dissipation, so they are not suitable for power supplies with large power requirements. However, because of their simple circuitry and low noise, they are frequently used in measuring instruments, medical equipment, and high-end audio equipment.

Switching power supplies have driven downsizing, weight reduction, and high efficiency

We finally get to the explanation of switching power supplies. One of the most common switching power supplies around us is the AC adapter of a mobile phone. While its circuit is far more complex than that of a rudimentary AC adapter mentioned earlier, it is exceptionally compact, thanks to ICs used in the stabilization circuit. The fact that it lacks a large and heavy power transformer explains its small size and weight.

Switching power supplies embody many technologies that have been at the core of power electronics over history. Starting around 1960, semiconductors (diodes, transistors, etc.) began to replace vacuum tubes, but size and efficiency improvements were slow to come. This was intrinsic to linear power supplies because heat sinks were necessary to dissipate the heat from transistors, and the transformers were heavy and bulky.

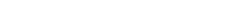

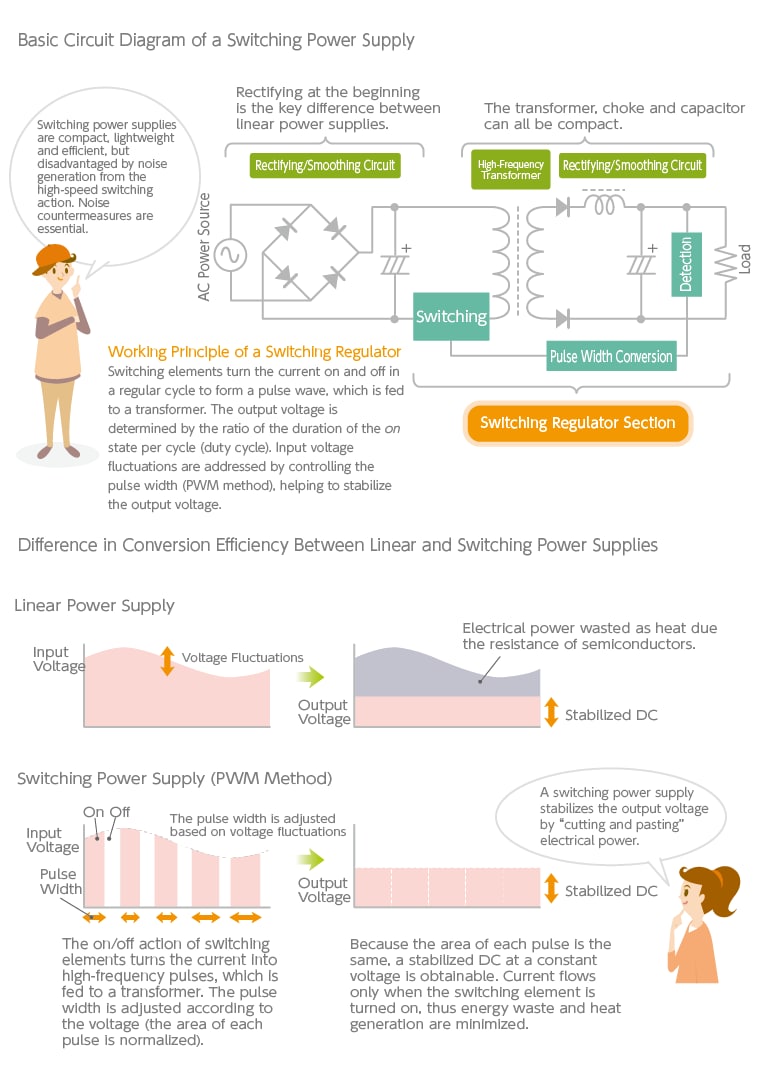

Switching power supplies took a completely different approach to overcome the disadvantages of linear power supplies. (Their development was boosted by NASA’s Apollo program.) The key difference between the two methods is that a linear power supply converts the commercial AC’s voltage using a transformer and rectifies it subsequently; a switching power supply first rectifies the AC to DC and converts the voltage afterward. Once a current is rectified, the voltage can no longer be converted with a transformer. Instead, semiconductors (transistors and MOS FETs) drive a high-speed switching action that converts the rectified current into a pulse wave, which is then fed to a high-frequency transformer that converts the voltage. This complicates the circuit and requires more components, but therein lies the essence of a switching power supply.

Several control methods for switching power supplies exist, but the PWM (pulse width modulation) method is most common. The widths of the pulses (the timing at which the current is switched on and off) are adjusted so that the “area” of each pulse (as represented in a graph) is normalized in an effort to stabilize the voltage. In terms of efficiency, this method is far superior to a linear power supply, which constantly discards part of the power as heat in the course of stabilization. A switching power supply is extremely efficient because it forms the output power as if it were cutting and pasting the waveform, with very little electrical power wasted.

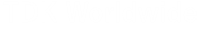

The size of a transformer is inversely proportional to the frequency it is designed to handle. The frequency of commercial AC is a low 50 or 60Hz, so the transformer in a linear power supply is inevitably large and heavy. On the other hand, a switching power supply’s pulse wave frequency is very high—tens to hundreds of kilohertz—where a much smaller and lighter transformer suffices. However, at high frequencies, transformers with iron cores become impractical because the power losses are excessive. This is where a ferrite core becomes indispensable. Just a 1% increase in the efficiency of power supplies, for example, can have a substantial energy-saving effect on society as a whole. This is why expectations are high for TDK’s ferrite technologies in the realm of power electronics. That said, switching power supplies also have their weaknesses: chiefly, the generation of noise due to high-speed switching. Traditionally, power supplies have long represented a battle against heat, and noise is an additional challenge. This is another area where TDK’s technologies come into play.

Conclusion

The evolution from linear to switching power supplies marks one of the most significant milestones in modern electronics. By harnessing high-frequency semiconductor control and ferrite-core technology, engineers achieved massive gains in efficiency, portability, and performance. TDK’s expertise in ferrite materials, EMI suppression, and magnetic design continues to shape the future of power electronics—enabling smaller, cooler, and greener devices that meet the energy demands of a connected, sustainable world.

FAQ

Q: Why were early AC adapters so heavy?

A: Linear power supplies relied on large, low-frequency iron-core transformers operating at 50/60 Hz, which made adapters bulky and heavy.

Q: What distinguishes linear from switching power supplies?

A: Linear supplies stabilize voltage through resistive regulation—simple but inefficient. Switching supplies use semiconductor-driven high-frequency switching, enabling compact transformers and high conversion efficiency.

Q: What is the role of a Zener diode or three-terminal regulator in a linear supply?

A: Both act as voltage stabilizers. The Zener diode maintains a constant reference voltage, while the three-terminal IC regulates output through feedback control and heat dissipation.

Q: How does PWM improve efficiency in switching supplies?

A: By varying the on/off duration of switching transistors, PWM maintains consistent average voltage with minimal power wasted as heat.

Q: Why is ferrite preferred over iron in switching transformers?

A: Ferrite has high resistivity and low eddy-current loss at high frequencies, enabling efficient, lightweight transformers for compact power supplies.

Q: What were the key innovations driving switching power technology?

A: The transition from vacuum tubes to semiconductors, NASA’s Apollo-era developments in compact electronics, and the advent of MOSFET-based switching control.

Q: What challenges remain with switching power supplies?

A: High-speed switching generates electromagnetic noise (EMI) and heat hotspots. Effective ferrite cores, filters, and shielding materials—like those from TDK—are vital countermeasures.

TDK is a comprehensive electronic components manufacturer leading the world in magnetic technology